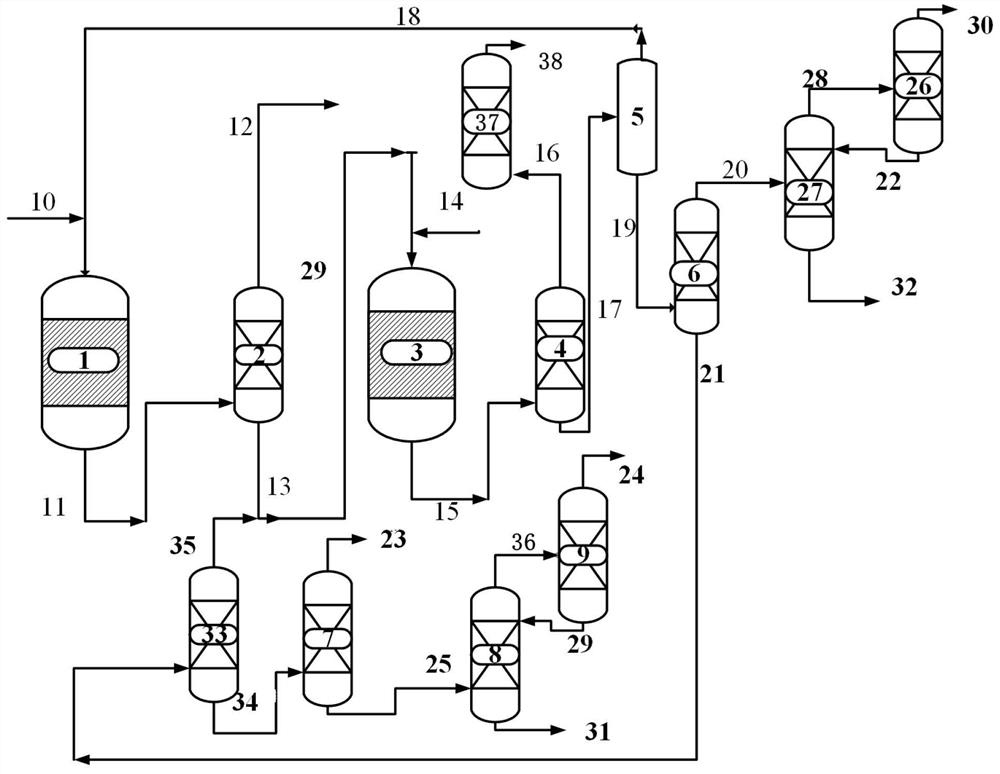

HFO-1234ze and HCFO-1233zd co-production process and co-production system

A technology of z-hcfo-1233zd and z-hfo-1234ze, applied in the field of fluorine-containing organic compounds, can solve the problems of reduced investment cost of equipment, no simultaneous preparation, low component content, etc., and achieves reduced operating cost and high selectivity , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Partially Fluorinated α-Al 2 o 3 preparation of

[0070] Weigh 204.3 grams of aluminum isopropoxide and place it in a polytetrafluoroethylene beaker, add 1L of ethylene glycol solvent, and use magnetic stirring to disperse it evenly; add nitric acid solution dropwise to the solution until the pH of the solution is 2, and continue stirring; The solution was slowly heated to 80°C and maintained at this temperature until the solution gradually became viscous; then the gel-like material was transferred into a stainless steel pan and dried in an oven at 120°C. The dried material is programmed from room temperature to 650°C at a heating rate of 3°C / min in a box furnace, and kept at 650°C for 3 hours, and then programmed at 3°C / min to 1200°C, and kept at 1200°C for firing 3 hours, the carrier α-Al was obtained 2 o 3 , specific surface area 15.53m 2 / g, the average pore diameter is 24.2nm, and more than 88% of the pore diameter is 15-35nm. α-Al 2 o 3 At 320°C...

Embodiment 2

[0071] Example 2: Partially fluorinated θ-Al containing 2 o 3 and α-Al 2 o 3 Preparation of mixed crystal phase alumina

[0072] Add aluminum isopropoxide to ethylene glycol to prepare a solution with an aluminum content of 1.0 mol / L, then treat at 150°C for 24 hours, centrifuge, wash the sample obtained by centrifugation with absolute ethanol, and store in air at 50°C Dry for 12 hours to obtain a powder, and bake the above powder in an air atmosphere at 1200°C for 3 hours to obtain a powder containing θ-Al 2 o 3 and α-Al 2 o 3 Crystalline alumina with a specific surface area of 15.3m 2 / g, the average pore diameter is 23.3nm, and more than 92% of the pore diameter is 15-35nm, among which, α-Al 2 o 3 The content is 85%, θ-Al 2 o 3 The content is 15%.

[0073] will contain θ-Al 2 o 3 and α-Al 2 o 3 Mixed crystal phase alumina at 350°C, HF / N 2 (HF:N 2 =1:3) under the atmosphere for 45 minutes to obtain partially fluorinated θ-Al 2 o 3 and α-Al 2 o 3 Alumi...

Embodiment 3

[0074] Embodiment 3: the preparation of the first catalyst

[0075] Weigh the required amount of Cr(NO 3 )3.9H 2 O and NiCl 2 ·6H 2 O (the mass ratio of Cr to Ni is 2:1) is dissolved in a certain amount of water, and partially fluorinated α-Al is added dropwise 2 o 3 immersion at 60°C for 18h and drying at 105°C for 6h to obtain the catalyst precursor 6%Cr-3%Ni / partially fluorinated α-Al 2 o 3 .

[0076] The catalyst precursor was placed in an Incon alloy tubular reactor with an inner diameter of 1 inch and a length of 90 cm, and nitrogen gas was introduced at 100 mL / min, and roasted at 200 ° C for 2 h, then raised to 500 ° C, and roasted for 3 h to obtain the first catalyst . Treat the first catalyst at 200° C. for 60 minutes in an HF atmosphere, and set it aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com