Method for extracting hydrocarbon oil from oil sand and producing ceramsite

A technology for oil sands and ceramsite, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, ceramic products, etc., can solve the problems that the device cannot realize large-scale industrialization, cannot realize comprehensive utilization, solid particle wear, etc. Realize the effect of comprehensive utilization of resources and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

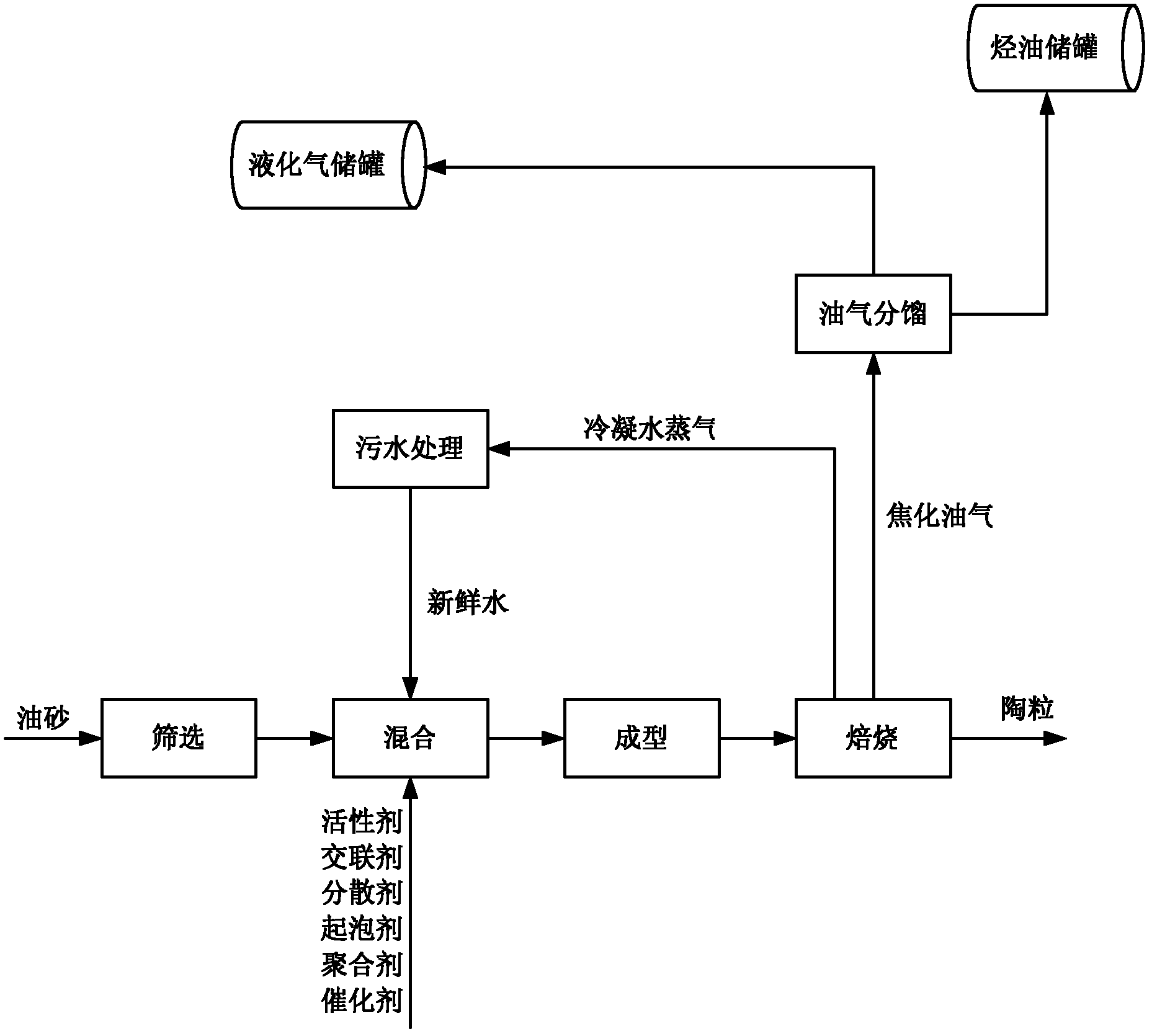

[0040] see figure 1 As shown, the present embodiment provides a method for producing hydrocarbon oil and ceramsite using oil-lubricating oil sands as a raw material, the method comprising the following steps:

[0041] Oil-lubricating oil sand raw ore mined on the surface or in shallow layers, with a bulk density of 0.65g / cm 3 , the water content is 3%, the oil content is about 15%, after proper drying and crushing, the particles with a particle size below 150 μm are screened, adding clean water, stirring in the reaction kettle, adding active agent, cross-linking agent and dispersant in sequence to produce a suspension, After stirring, add foaming agent to generate foam, then add polymerization agent and catalyst, and inject into mold before gel generation. Among them, the various material components are:

[0042] Active agent (acrylamide)

[0043] Cross-linking agent (N, N'-methylenebisacrylamide)

[0044] Dispersant (2,3,5-triphenyltetrazolium)

[0045] Foaming agent (po...

Embodiment 2

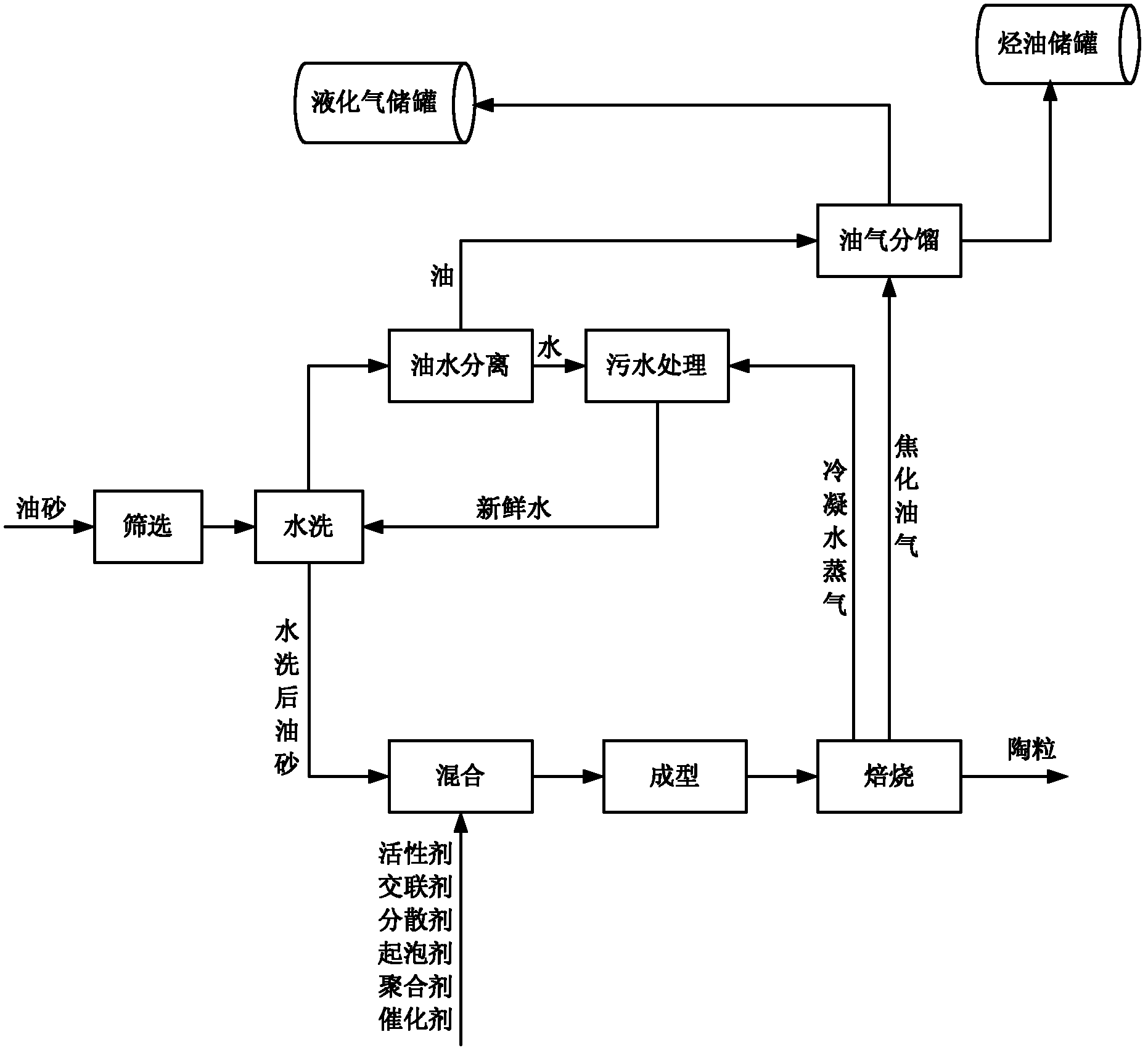

[0064] see figure 2 As shown, the present embodiment provides a method for producing hydrocarbon oil and ceramsite with water-wettable oil sand as a raw material, the method comprising the following steps:

[0065] The water-moistened oil sand raw ore mined on the surface or shallow layer is a mixture of asphalt, sand, rich ore clay and water, containing 3% to 6% of water, 6% to 20% of asphalt, and the balance is inorganic matter ( sand, minerals, clay, etc.), the porosity is about 35%. This type of oil sand is pulverized, and through the screening process to remove larger gravel and other sundries, inject fresh water, heat to 90°C, mix and stir, and after fully circulating and washing, the oil-water mixture enters the oil-water separation unit to separate the crude crude.

[0066] Part of the sewage (still containing a small amount of oil) after the crude oil is separated is reinjected and circulated, and the rest passes through a traditional sewage treatment unit. In this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com