Manufacturing method of embedded metal through-hole wafer and device thereof

A technology of metal through holes and manufacturing methods, which is applied in the direction of manufacturing microstructure devices, microstructure devices, metal material coating technology, etc., and can solve problems such as high cost, limited application, unfavorable mass production of pre-embedded metal through hole wafers, etc. , to achieve the effect of realizing manufacturing, realizing mass production and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the utility model of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] The present invention relates to a method for manufacturing a pre-buried metal through-hole wafer. In this embodiment, it is a method for manufacturing a glass wafer, which includes the following steps:

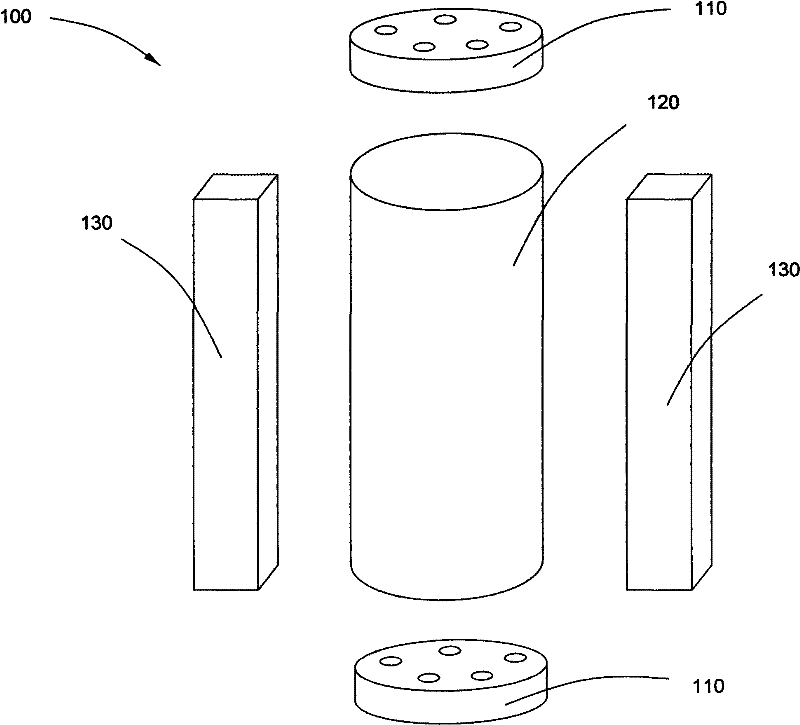

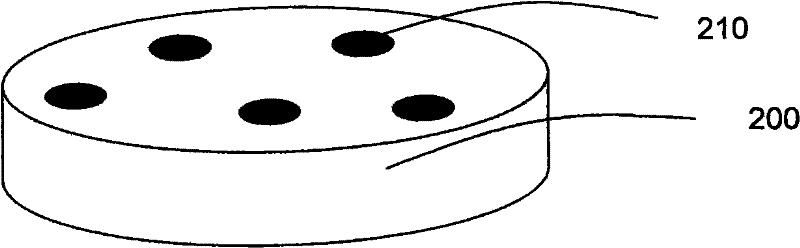

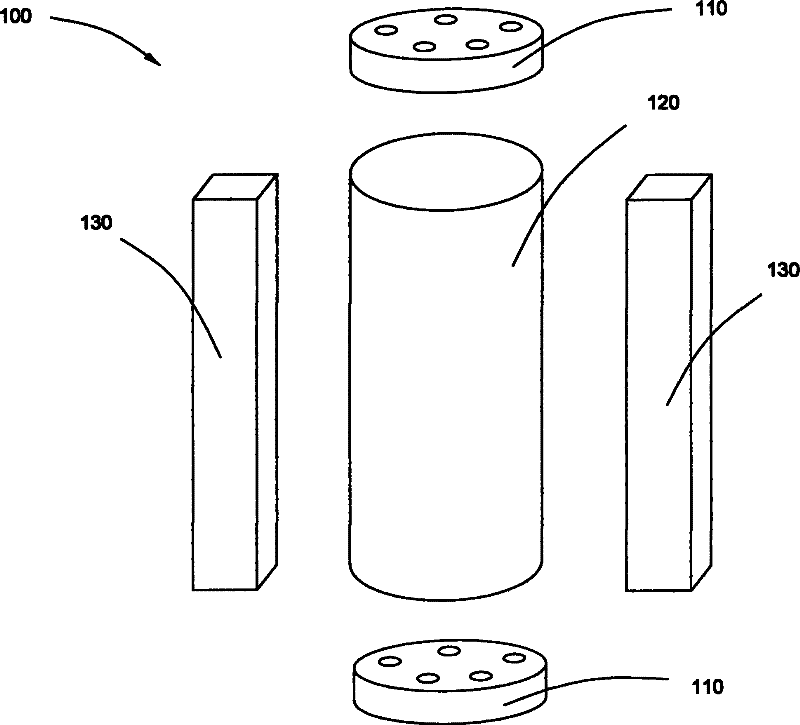

[0027] The first step is to provide a pair of load-bearing devices, a high-temperature resistant mold, and a number of metal tungsten wires; the load-bearing device is preset with a number of through holes; and the mold is provided with a cylindrical housing cavity, and the bottom is provided with a number of through holes for Connect the inside of the receiving cavity with the outside of the mold.

[0028] In the second step, pass the tungsten wire through a carrying device and the through hole at the bottom of the mold, and after passing through the cavity of the mold, pass through the through hole of another carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com