Continuous shearing and pressing device for rigid thin band

A thin belt, pressing technology, applied in the direction of shearing device, laminating device, attachment device of shearing machine, etc. The effect of compact structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

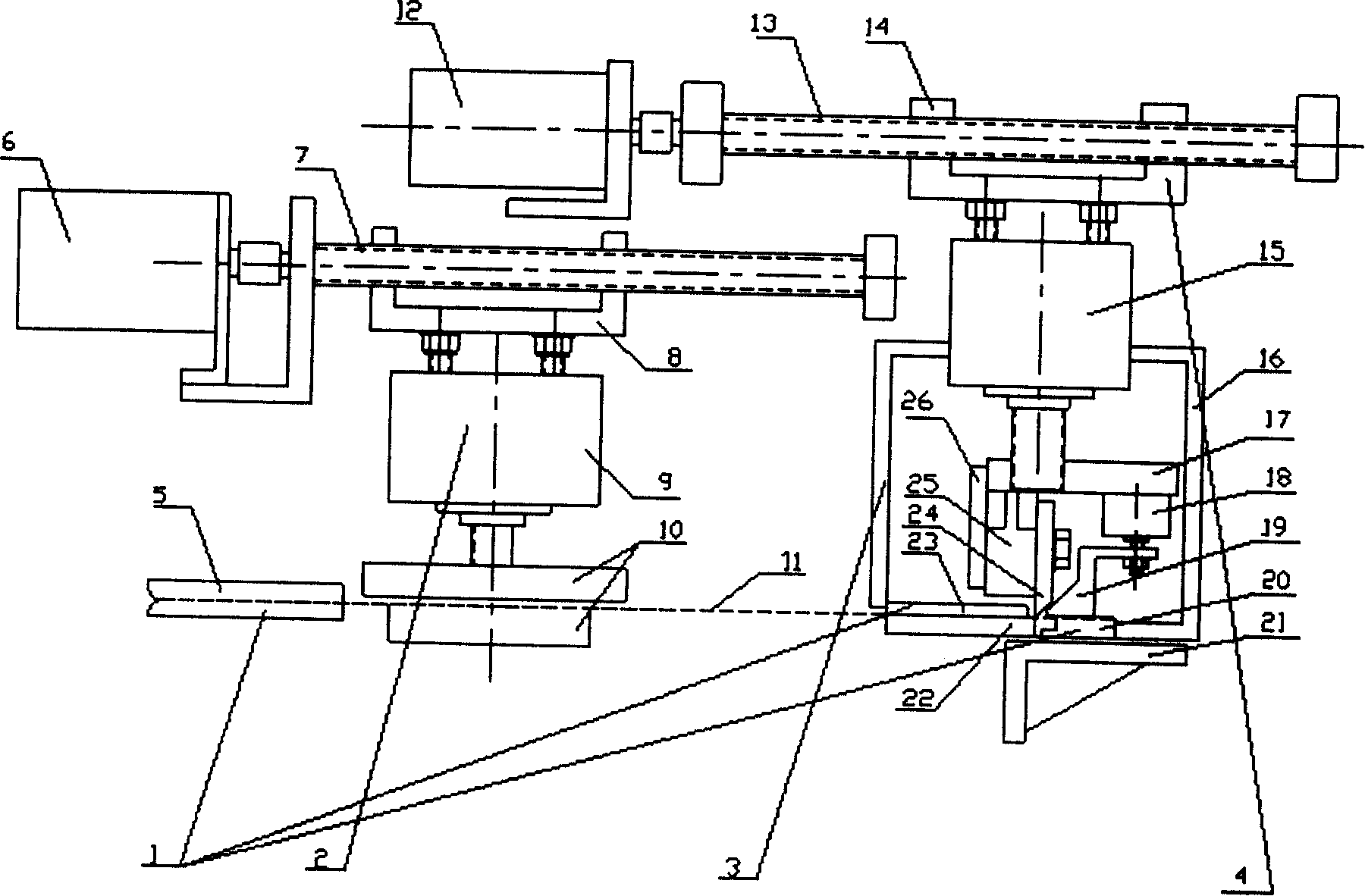

[0014] Such as figure 1 As shown, the present invention includes: a strip guiding part 1, a strip pinching part 2, a strip cutting and pressing part 3 and a displacement part 4 of the strip cutting and pressing part. The strip guide part 1 includes: a guide plate 5, a material retaining grid 20, and a material guide grid 23; the strip pinch part 2 includes: a drive motor 6 for the pinch part, a transmission mechanism 7 for the pinch part, and a sliding connection block for the pinch part 8. Clamping cylinder 9, clamping plate 10; strip cutting and pressing parts 3 include: shearing cylinder 15, cylinder mounting plate 16, punch mounting plate 17, pressing cylinder 18, pressing plate 19, lower Blade 22, scissors 24, connecting block 25, scissors guide plate 26; The shifting part 4 of strip shearing and pasting part comprises shearing and pasting displacement part driving motor 12, shearing and pasting displacement part transmission mechanism 13 and The sliding connection block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com