Alkali concentrated flake device capable of simultaneously producing different concentrations of solid caustic soda

A technology of sheeting and equipment, applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of high energy consumption, high product cost, and a single product, so as to reduce production Energy consumption, reduced production costs, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

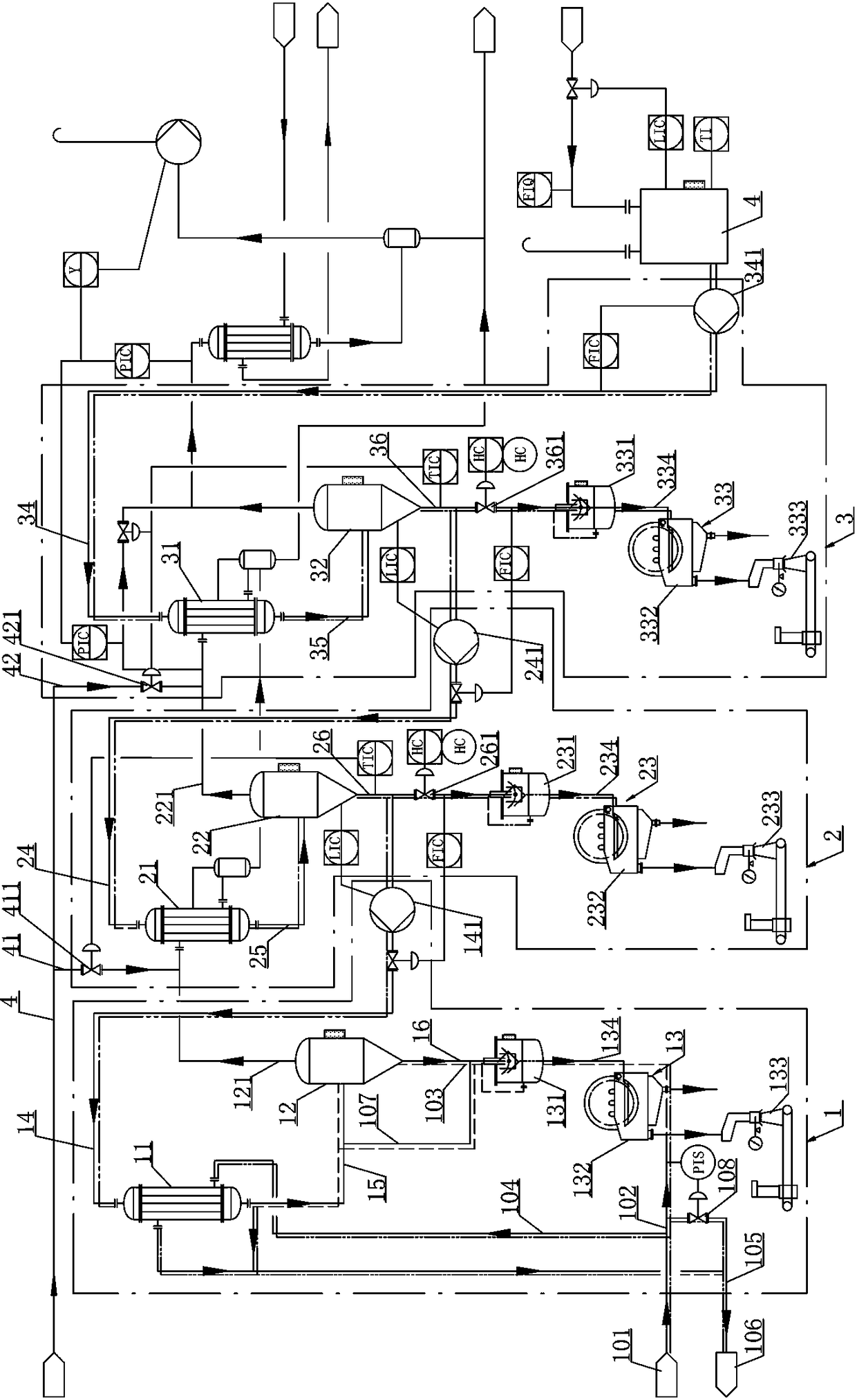

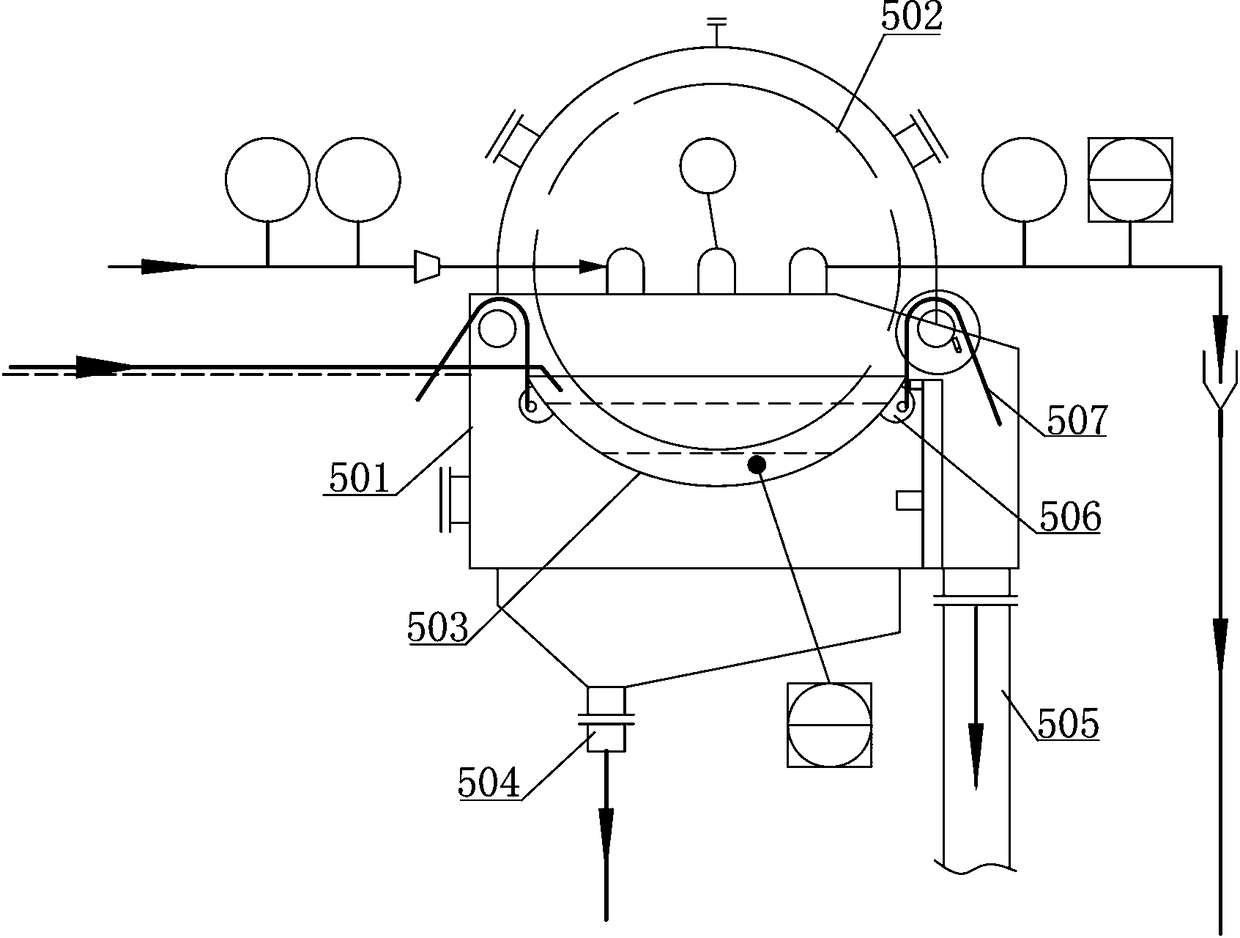

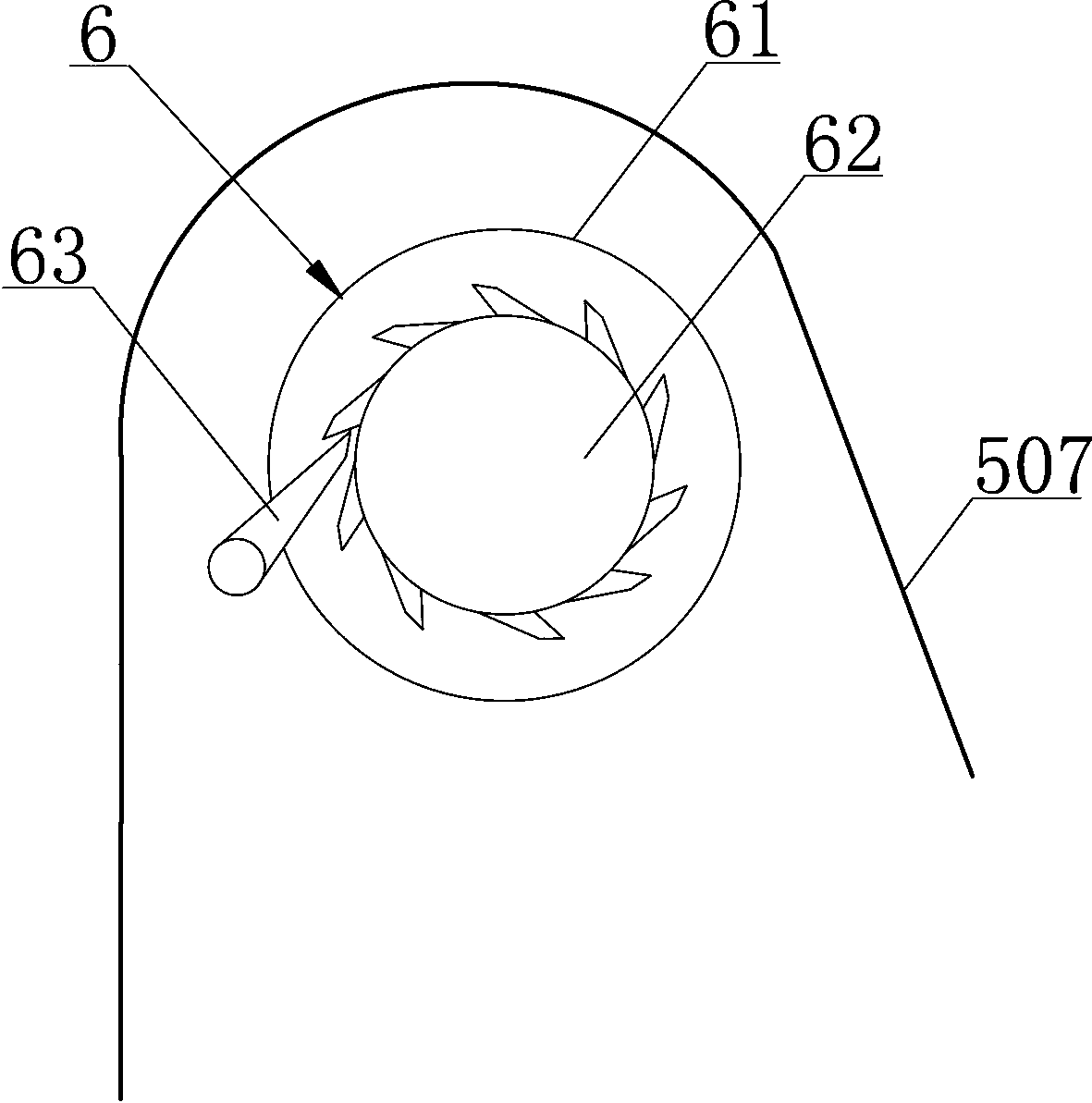

[0018] Such as figure 1 As shown, the alkali concentration sheeting equipment capable of simultaneously producing different concentrations of solid alkali includes: an alkali solution tank 4, and also includes a three-effect concentration sheeting mechanism 3, a second-effect concentration sheeting mechanism 2 and a one-effect concentration sheeting mechanism 1.

[0019] Wherein the three-effect concentration sheeting mechanism 3 includes: a three-effect evaporator 31 , a three-effect separator 32 and a three-effect sheeting mechanism 33 . The feed port of the three-effect evaporator 31 is provided with a three-effect feed pipe 34, the three-effect feed pipe 34 communicates with the lye tank 4, and the three-effect feed pipe 34 is provided with a three-effect feed pump 341, and the three-effect feed The pump 341 can continuously pump the lye to the three-effect evaporator 31, the output port of the three-effect evaporator 31 is provided with a three-effect evaporator output pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com