Trolley type electrolyte fertilizer production and spraying device

A spraying device and production device technology, applied in the electrolysis process, electrolysis components, liquid fertilizer pressurized spreading method, etc., can solve the problems of inconvenient use of flow-type electrolytic cells, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

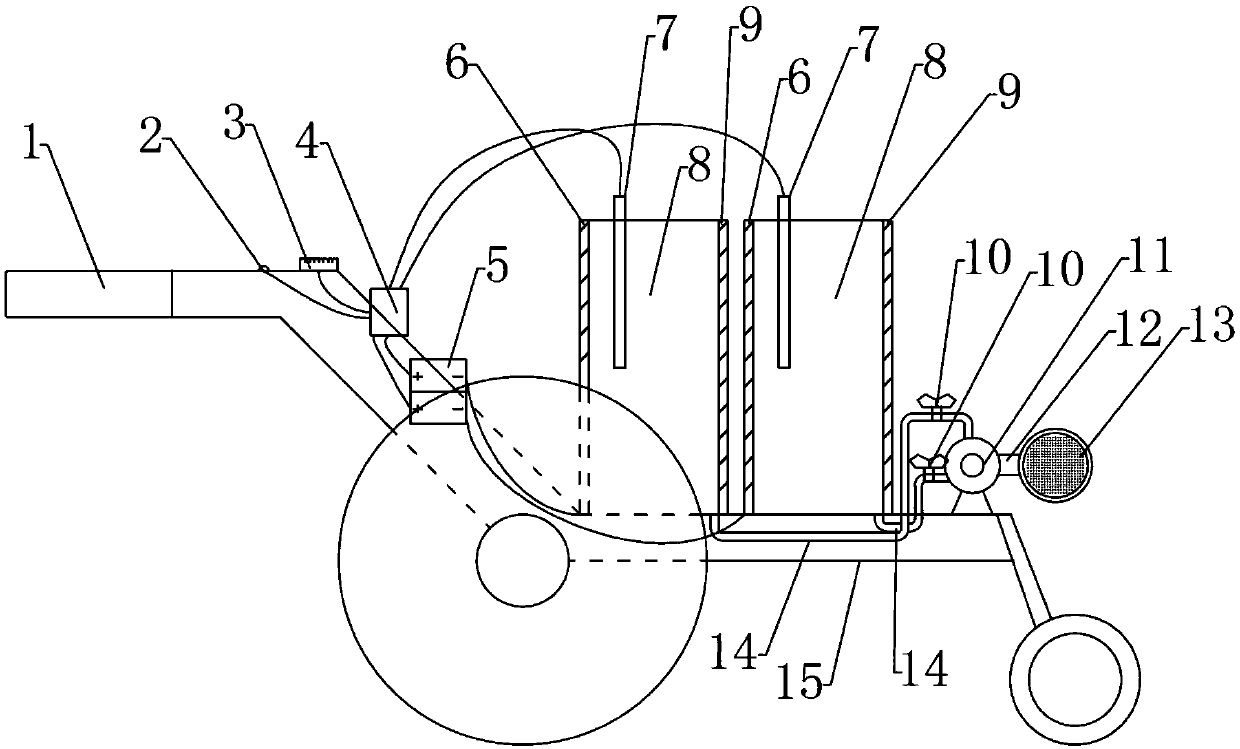

[0027] A trolley-type electrolyte fertilizer production and spraying device includes a pusher 1 and a car body 15 on which an electrolyte fertilizer production device, a liquid suction pump 11 and a sprinkler head 13 are installed. The installation direction of the sprinkler head 13 is towards the side of the vehicle body 15, and a connecting pipe 12 is arranged between the sprinkler head 13 and the liquid suction pump 11, and the connecting pipe 12 is a corrugated pipe. The electrolytic fertilizer production device comprises an electrolysis chamber 8. A cathode plate 6 and an anode plate 9 are arranged in the electrolysis chamber 8. A liquid outlet pipe 14 is arranged at the bottom of the electrolysis chamber 8. The liquid outlet pipe 14 is connected with a liquid suction pump 11, and the liquid outlet pipe 14 A valve 10 is arranged on it.

[0028] This embodiment is a cart-type electrolyte fertilizer production and spraying device with simple structure and easy to use. After...

Embodiment 2

[0030] A trolley-type electrolyte fertilizer production spraying device includes a pusher 1 and a car body 15 on which two electrolyte fertilizer production devices, a liquid suction pump 11 and a sprinkler head 13 are installed. There are two sprinkler heads 13, and the installation direction of the two sprinkler heads 13 is to face the two sides of the vehicle body 15 respectively. A connecting pipe 12 is arranged between the sprinkler head 13 and the pump 11, and the connecting pipe 12 is a corrugated pipe. . The electrolytic fertilizer production device comprises an electrolysis chamber 8. A cathode plate 6 and an anode plate 9 are arranged in the electrolysis chamber 8. A liquid outlet pipe 14 is arranged at the bottom of the electrolysis chamber 8. The liquid outlet pipe 14 is connected with a liquid suction pump 11, and the liquid outlet pipe 14 A valve 10 is arranged on it. The electrolytic fertilizer production device also includes a detection device 7, a power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com