Automatic knife sharpener

A knife sharpening machine and automatic technology, which is applied in the directions of grinding machine parts, grinding workpiece supports, grinding drive devices, etc. High efficiency, flexible use, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

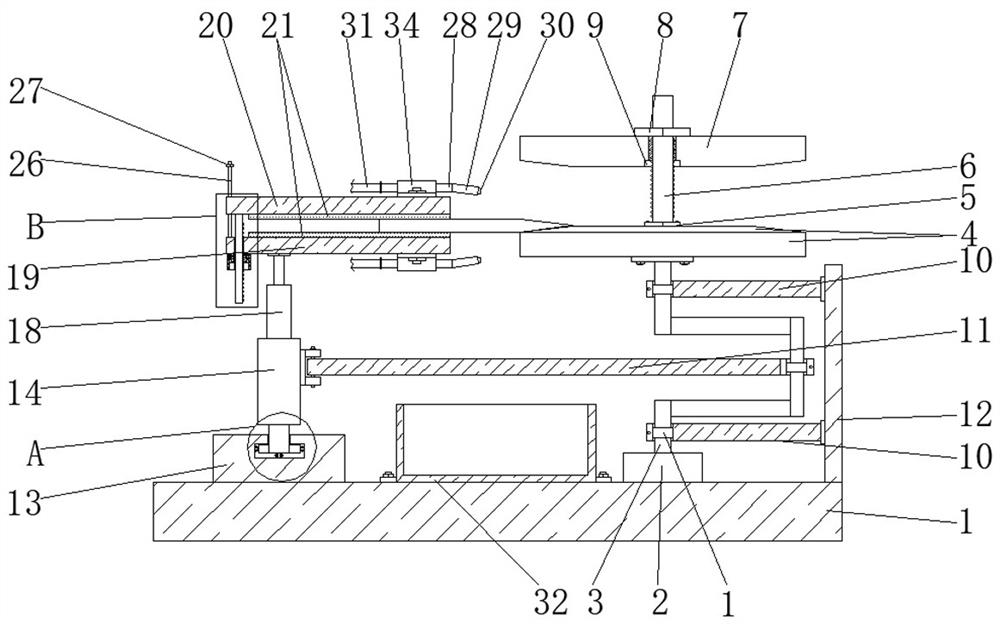

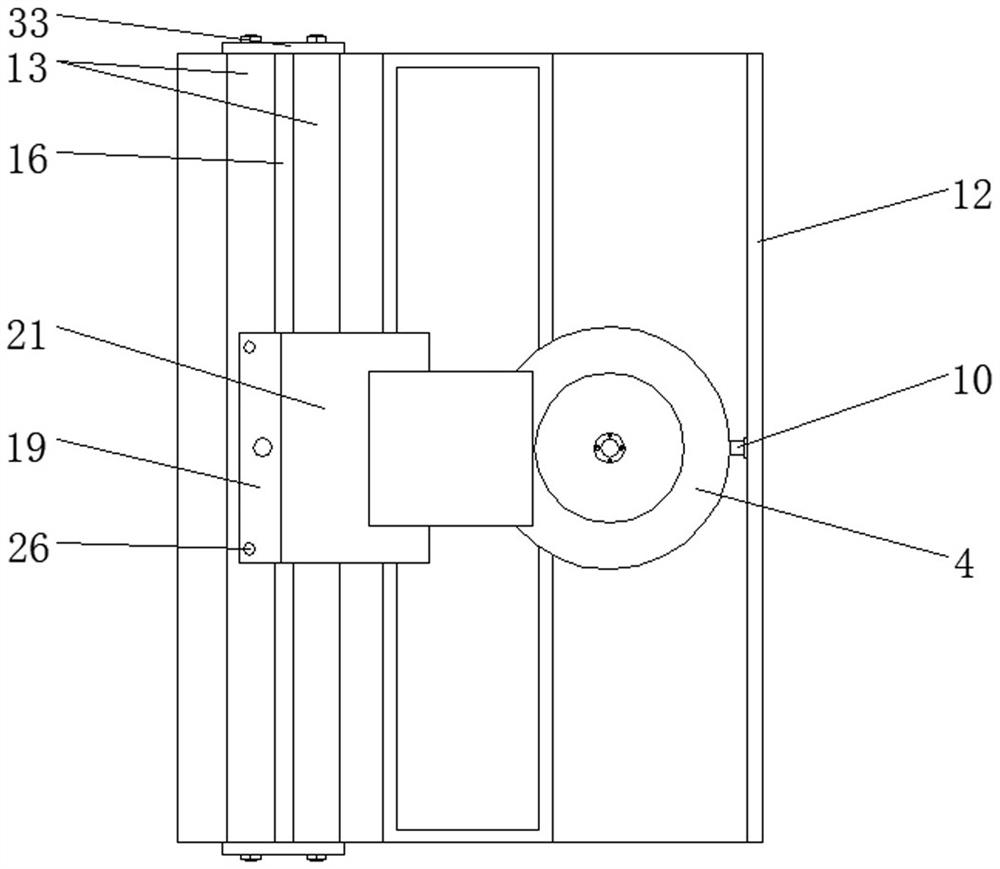

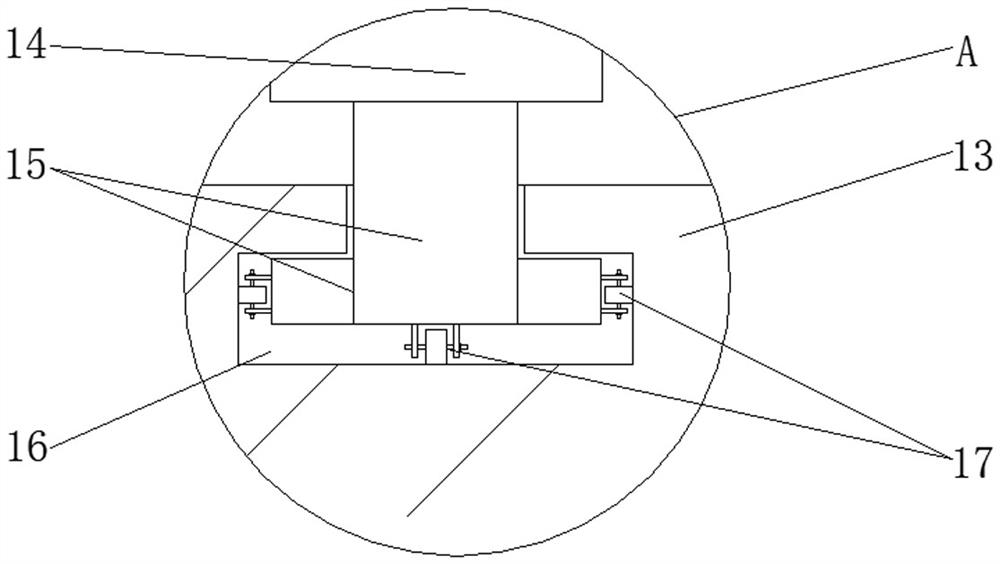

[0029] like Figure 1-4A kind of automatic sharpening machine shown, comprises base 1, motor 2, rotating shaft 3, annular whetstone 4 and fixed block 5, and the top of base 1 is equipped with vertically arranged motor 2, and the output end of motor 2 A rotating shaft 3 is connected, and the top of the rotating shaft 3 is connected with a horizontally arranged ring-shaped whetstone 4 through a fixed block 5. A clamping mechanism for fixing the blade is provided above the base 1, and the middle part of the top of the ring-shaped whetstone 4 passes through Another fixed block 5 is connected with a first threaded rod 6, and the first threaded rod 6 is perpendicular to the ring whetstone 4, and the threaded sleeve on the first threaded rod 6 is provided with a press-fit whetstone parallel to the ring whetstone 4 Stone 7, and the pressing whetstone 7 has the same shape as the ring-shaped whetstone 4, and the pressing whetstone 7 and the ring-shaped whetstone 4 are arranged oppositel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com