Automatic wire cutting and pressing machine for flat braided wire

A braided wire and flat wire technology, applied in the field of crimping machines, can solve the problems of inability to accurately control the cut length, difficult braided wire ends are fed into terminals, and flat braided wires cannot be crimped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

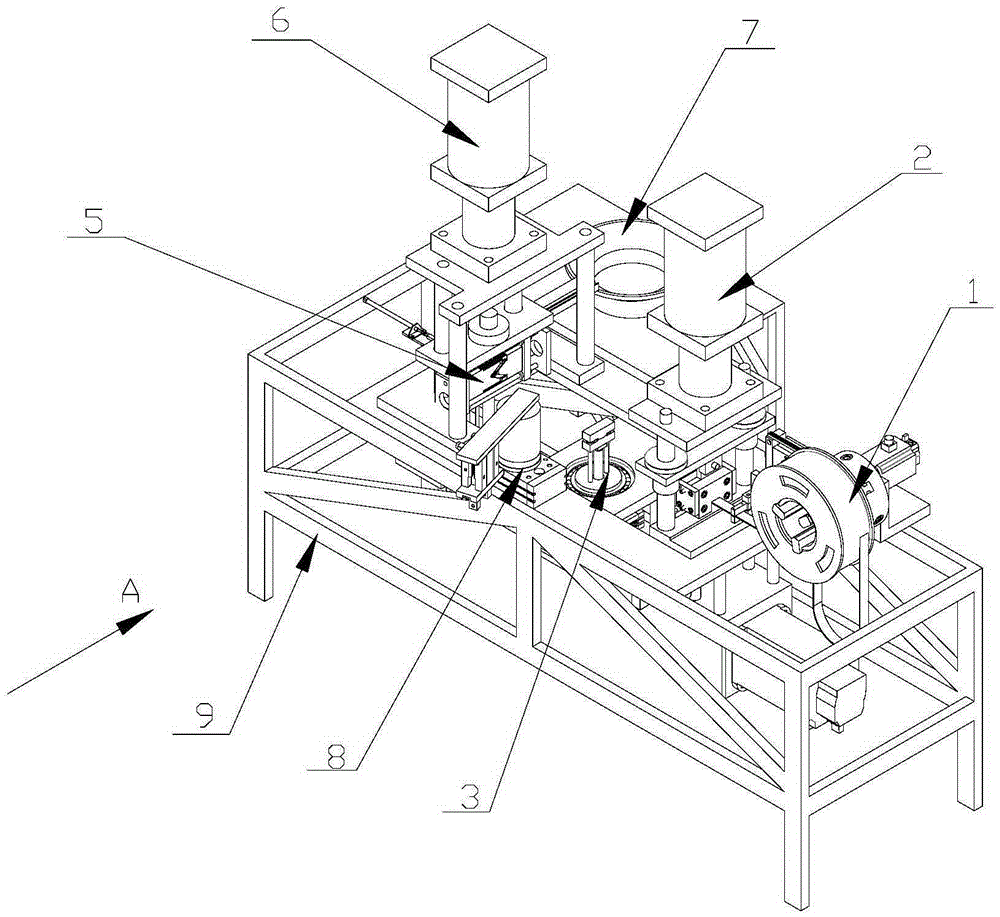

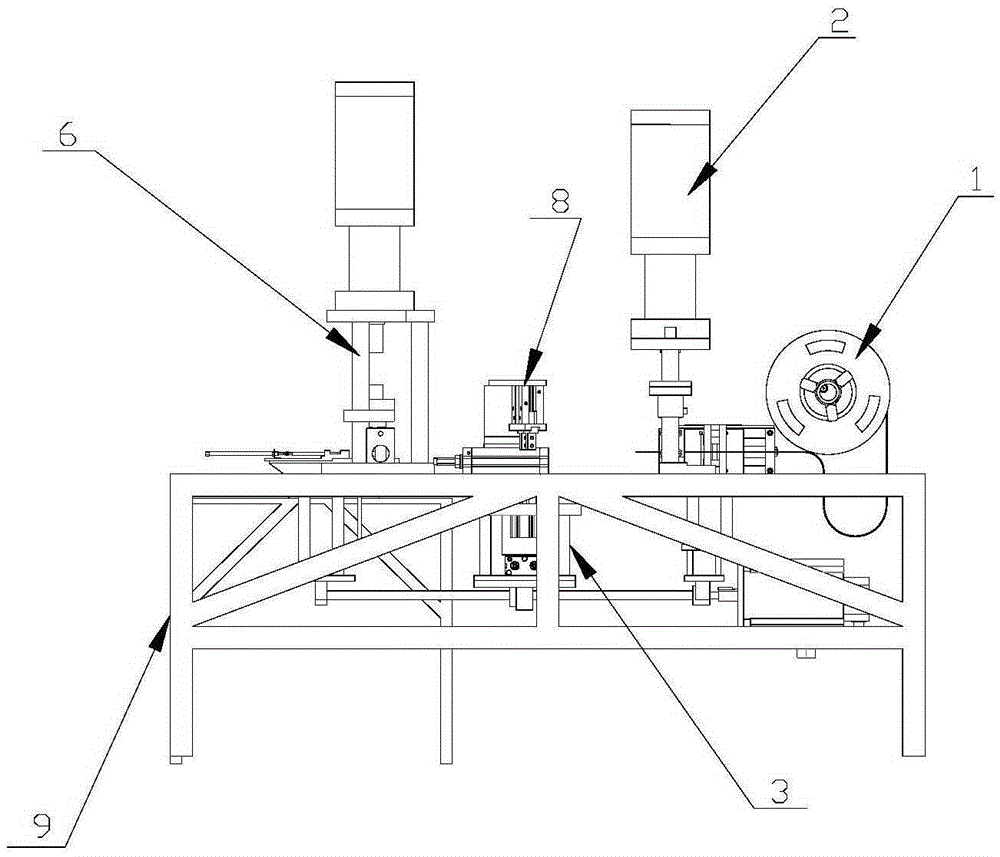

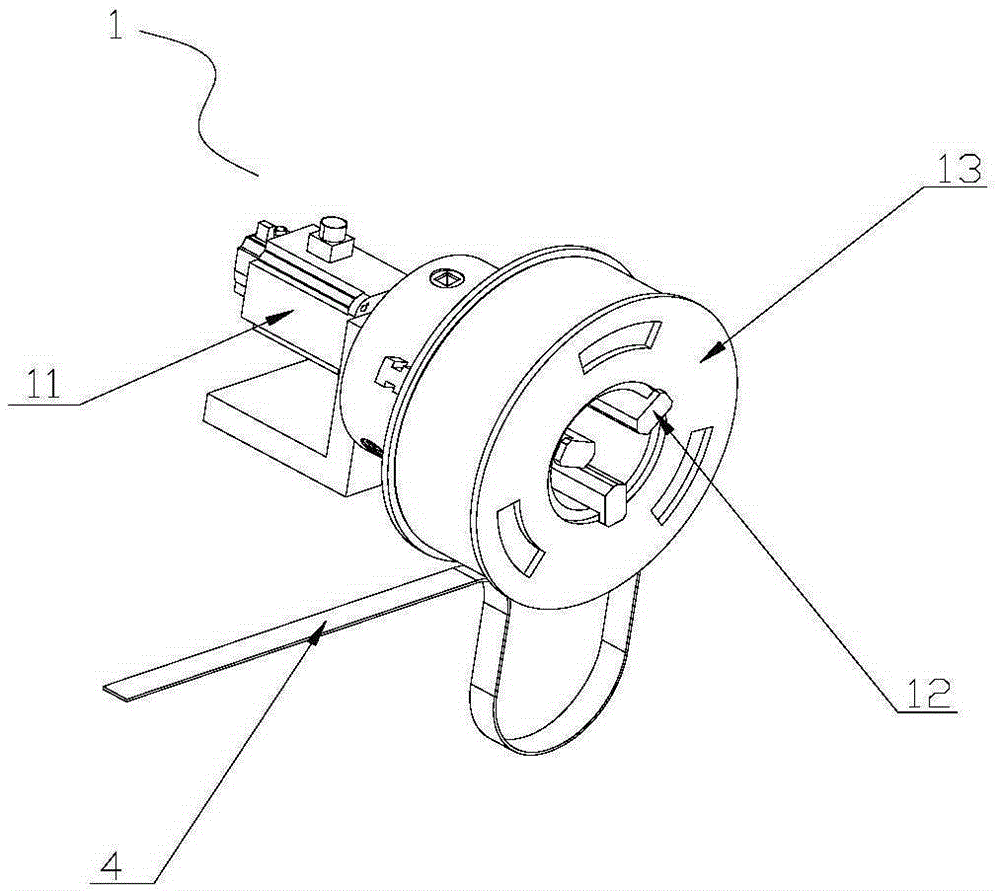

[0043] Please refer to figure 1 with figure 2 As shown, an automatic cutting and crimping machine for flat braided wire mainly has a frame 9, a wire feeding mechanism 1, a wire cutting mechanism 2, a wire clamping mechanism 3, a wire winding mechanism 5, a crimping mechanism 6, and a vibration plate mechanism 7 and discharge mechanism 8 form. Wherein, the frame 9 is used as the support of the whole flat braided wire automatic cutting and crimping machine, and all the other mechanisms are installed on the frame 9 . The wire feeding mechanism 1 is used to install the flat wire 4 (such as flat copper wire) and transfer the flat wire to the wire cutting mechanism 2; Send it to the thread gathering mechanism 5; the thread clamping mechanism 3 is located between the thread cutting mechanism 2 and the thread gathering mechanism 5, and is used to clamp one end of the flat thread 4, and pull the flat thread 4 to a set length, so that the thread cutting mechanism 2 Cut the flat wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com