Rotary touch obstacle meeting mechanism, power integration mechanism and clothes drying machine

A technology of rotating contact and encountering resistance, which is applied in the direction of clockwork mechanism, washing device, textile and paper making, etc. It can solve the problems of large size, easy impact of drying rod on user's head, and inability to control the suspension of drying rod in the first place. , to achieve the effect of reducing the overall volume, improving accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

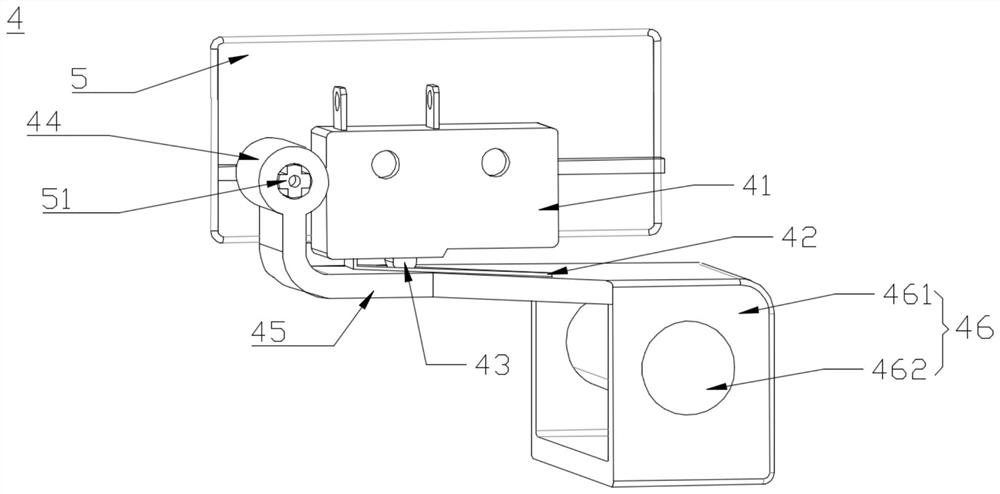

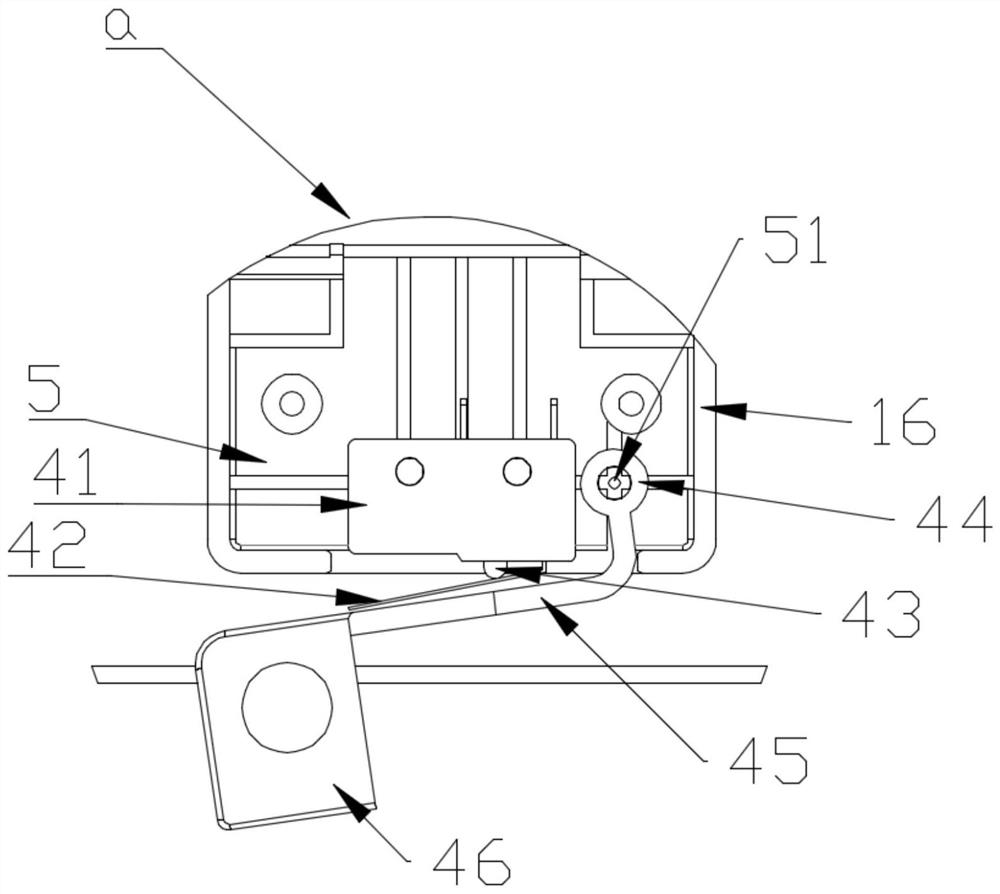

[0046] This embodiment provides a rotary touch resistance mechanism 4, which uses the switch shrapnel 42 instead of the traditional spring to realize the reset function, and the overall size of the resistance mechanism 4 can be further reduced through the bending structure of the pressing part and the effect of rotation resistance. volume.

[0047] Such as figure 1 As shown, the rotary touch resistance mechanism 4 in this embodiment includes a cover plate 5, and the cover plate 5 is used as a carrier so that both the pressing member and the main body member 41 can be arranged on the cover plate 5 to limit the resistance. The positional relationship between the pressing piece and the main piece 41.

[0048]The body part 41 is fixed on the cover plate 5, and any side wall of the body part 41 is provided with a switch elastic piece 42. The switch elastic piece 42 has a certain elasticity relative to the body part 41. Elastic deformation can occur. The switch elastic piece 42 c...

Embodiment 2

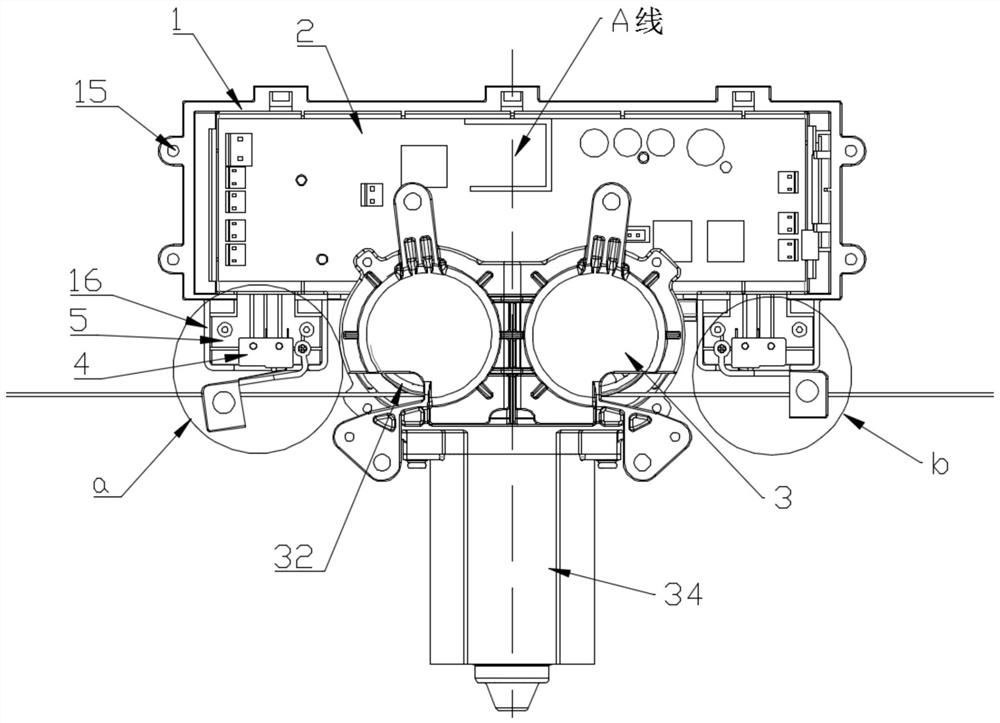

[0059] This embodiment provides a power integration module, which integrates the main control board 2, the resistance mechanism 4 and the winding device 3 in the first embodiment on a box body 1, so that the power integration module is small in size and compact in structure, making The internal wiring is neat and orderly, which can speed up the efficiency of disassembly and assembly while eliminating potential safety hazards, and improve the internal aesthetics.

[0060] Such as Figure 2-7 As shown, the power integration module of this embodiment includes a box body 1 , a main control board 2 mounted on the box body 1 , a winding device 3 and the resistance mechanism 4 in the first embodiment. Wherein the box body 1 includes a bottom plate 11 and a surrounding plate 12, the surrounding plate 12 is vertically connected to the edge of the bottom plate 11, so that the two jointly define an accommodation space, which can be used to accommodate the main control board 2 and other ...

Embodiment 3

[0073] This embodiment provides a clothes dryer, including a clothes dryer host and a power integration module as described in Embodiment 2; Figure 8 As shown, the host is provided with a bottom panel 6, and the box body 1 is reversely installed on the bottom panel 6, so that the bottom panel 6 blocks the accommodating space. At the same time, in order to install the box body 1 on the bottom panel 6 of the main body of the washing machine, at least one side wall fixing hole 15 extending outward is provided on each of the short side walls 121, and the The side wall fixing hole 15 is not in contact with the bottom plate 11, that is, the side wall fixing hole 15 can be arranged on the upper edge of the short side wall 121, or in the middle of the short side wall 121, but always Keep a certain distance from the bottom plate 11, so that when the box body 1 is installed on the bottom panel 6 of the clothes dryer, the accommodating space is facing the bottom panel 6 of the clothes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com