Press-fit device for new energy automobile battery control panel and connector

A technology for battery control panels and new energy vehicles, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of safety hazards, low efficiency, time-consuming and labor-intensive manual operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

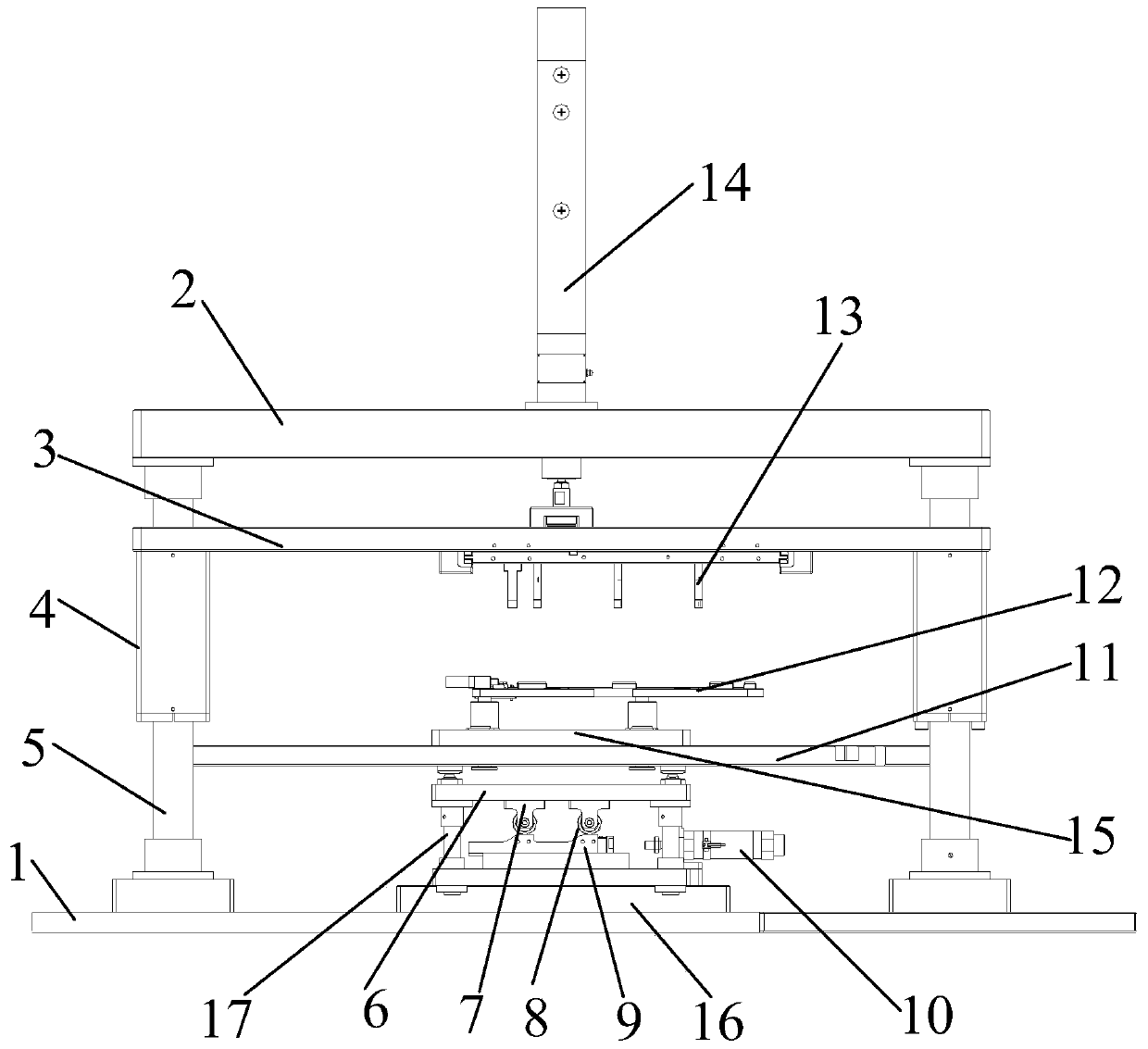

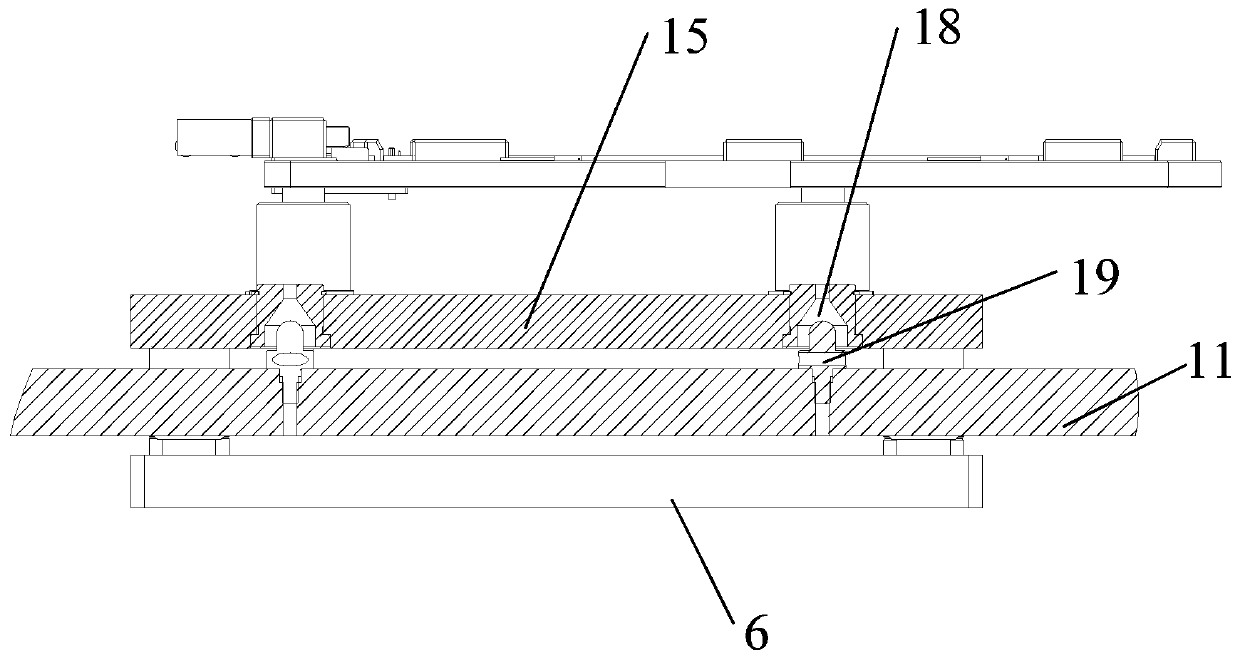

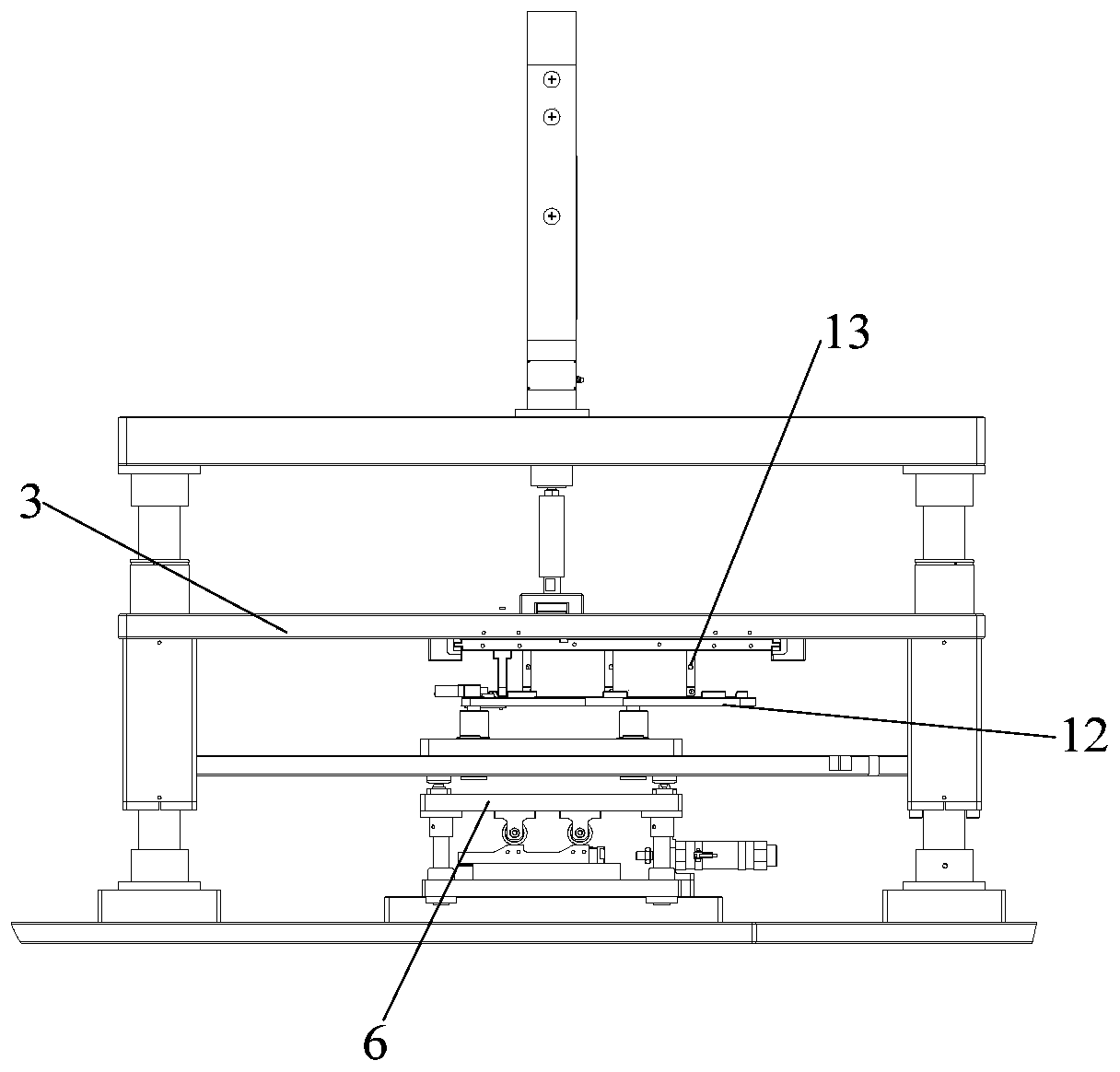

[0023] Such as figure 1 As shown, the pressing device of the new energy vehicle battery control board and the connector is erected on the workbench 1 with four uprights 5, and the four uprights are distributed in the form of four vertices of a regular quadrilateral, and the moving beam 3 is placed through the guide sleeve 4. On the column 5, a fixed beam 2 is fixed horizontally on the top of the column, and a servo press 14 is installed on the fixed beam 2. The lead screw of the servo press 14 passes through the fixed beam 2 and is connected with the moving beam 3 to drive the moving beam 3 Move up and down along the column, the bottom surface of the moving beam 3 is distributed with pressure heads 13, the turntable 11 is installed on the turntable on the worktable, the control board fixed plate 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com