Self-adaptive hoisting device of skylight assembly production line

A technology for assembling production lines and lifting devices, which is applied in the directions of lifting devices, lifting frames, assembling machines, etc., can solve the problems of reducing production efficiency, and the assembly and transfer of skylights is not a very process, so as to improve production efficiency and solve the inability to quickly adapt to positioning. , the effect of fast adaptive positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

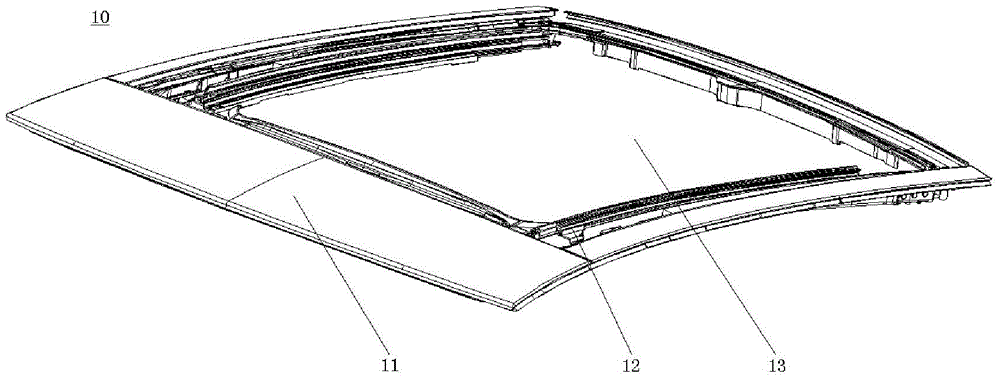

[0029] figure 1 Schematic diagram of the structure of the panoramic sunroof.

[0030] like figure 1 As shown, the panoramic sunroof 10 is composed of three parts covering plastic plate (PC-COVER) 11, sunroof frame 12 and sunroof glass 13, and the three are glued together and formed by pressing on the curing line. The sunroof frame is fully injection-molded, the front end is very weak, and the size difference is large, it is not easy to position, and the overall rigidity is poor.

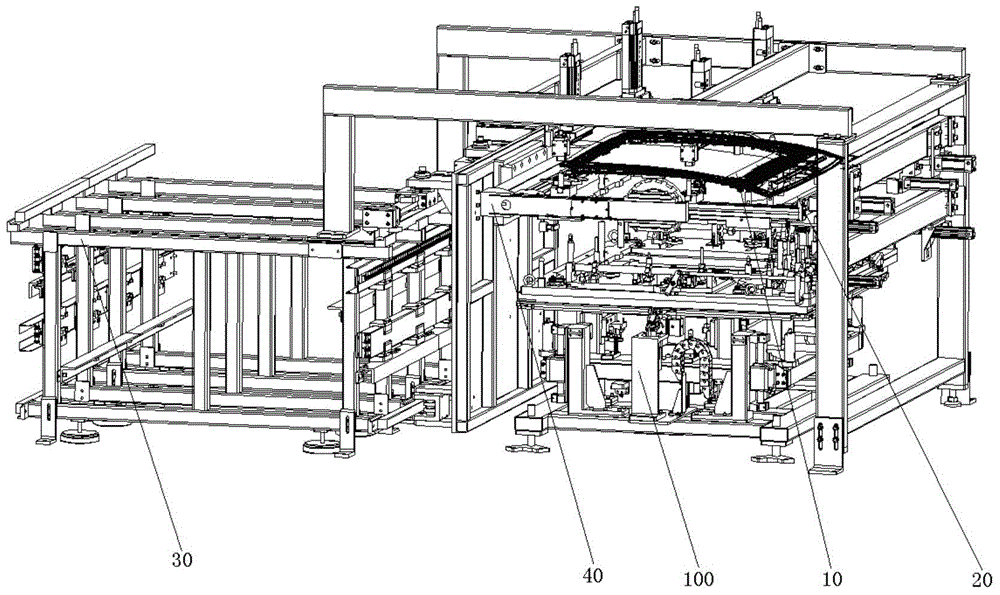

[0031] figure 2 It is a schematic diagram of the mechanism of the panoramic sunroof transfer workstation.

[0032] like figure 2 As shown, the transfer workstation includes: an adaptive lifting device 100 , a main line 30 , a curing line 20 and a transfer trolley 40 . The adaptive lift device 100 is located on the curing line 20 . Curing line 20 and main line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com