Film mounter and film mounting method thereof

A placement machine and patch technology, applied in optics, instruments, packaging, etc., can solve the problems of easy generation of bubbles or creases, poor quality of artificial film, waste of manpower and material resources, etc., to improve quality, improve patch efficiency, Guarantee the effect of film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

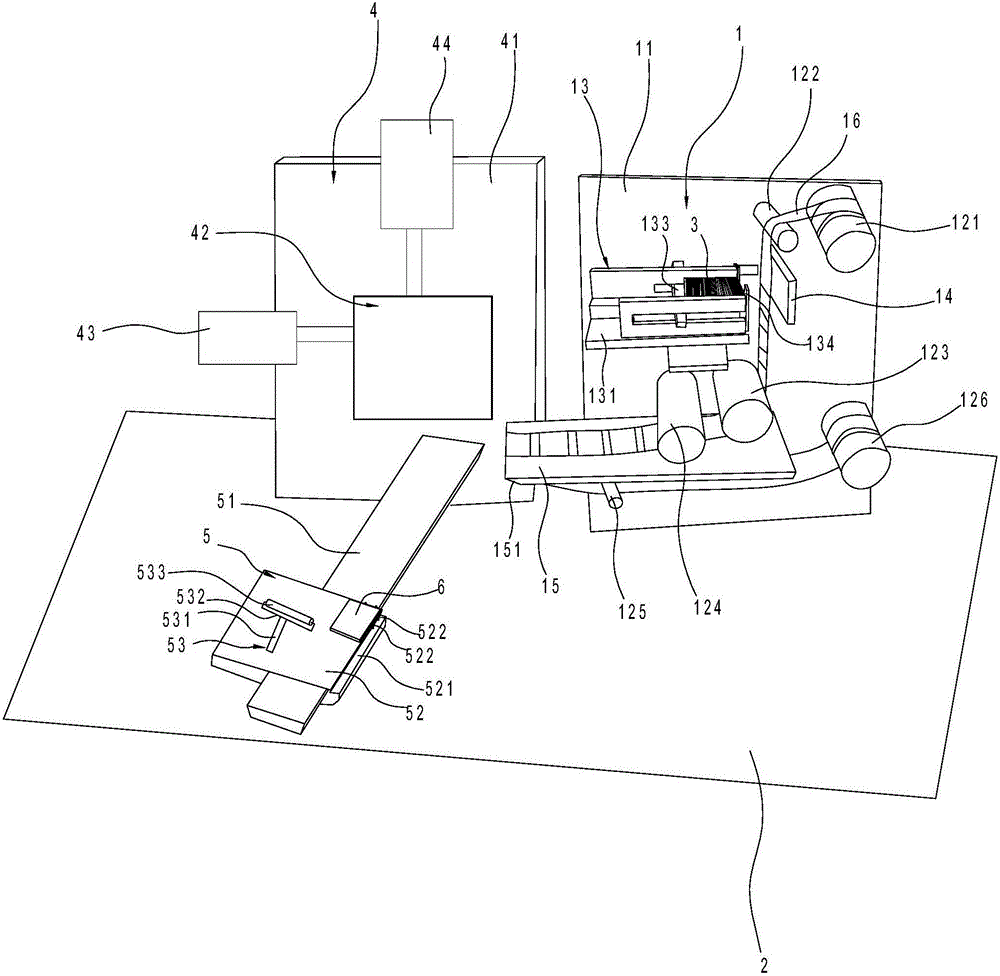

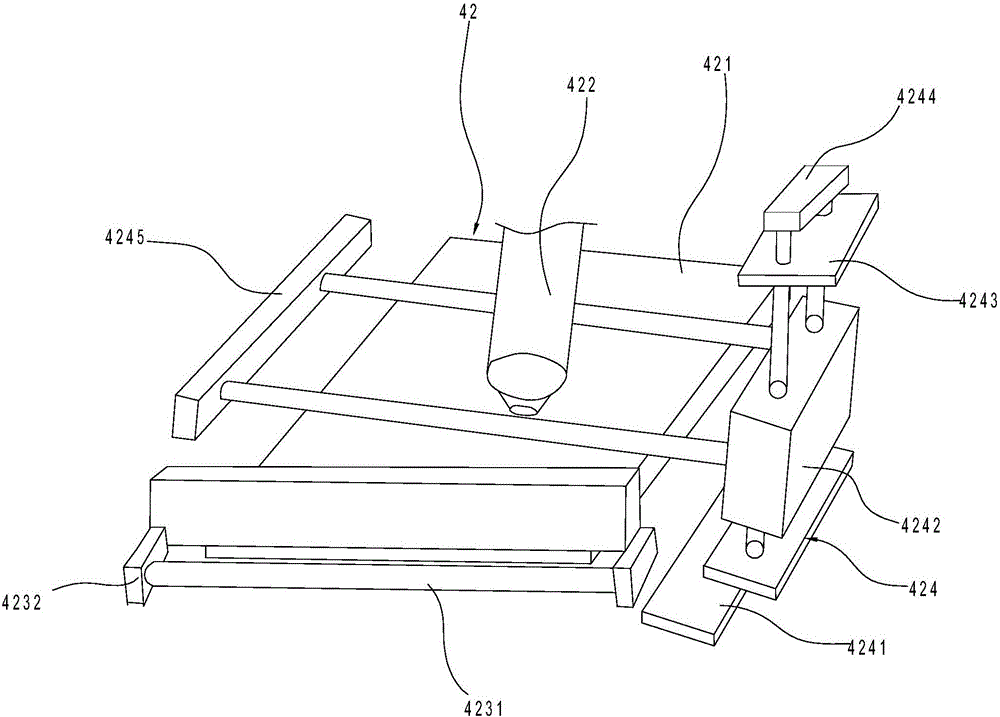

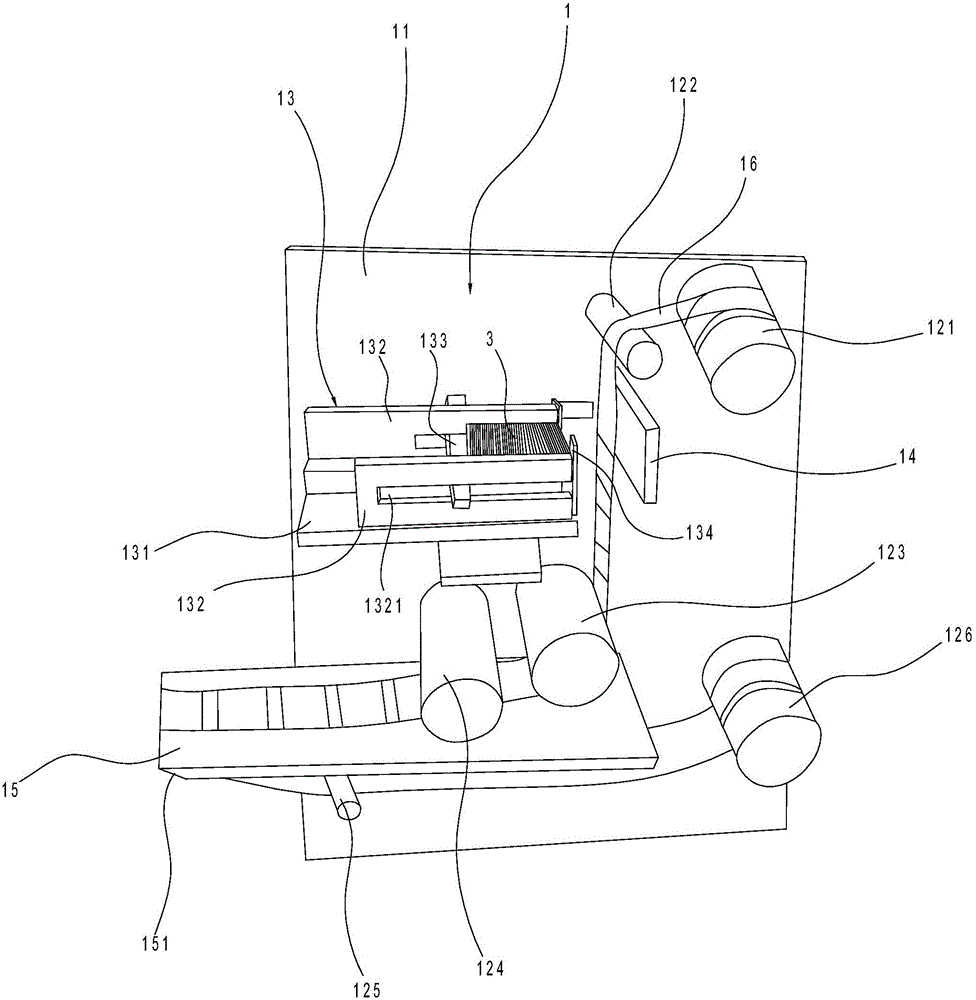

[0031] like Figures 1 to 4 As shown, the placement machine in this implementation includes a machine platform 2, a film tearing device 1 arranged on the machine platform 2, a chip mounting device 4 and an upper board device 5, and the film tearing device 1 is located on the right side of the chip mounting device 4 , the upper plate device 5 is located on the front side of the placement device 4 .

[0032] Wherein, the film tearing device 1 comprises a tear film vertical plate 11 erected on the machine platform 2, and the film tear vertical plate 11 is provided with an adhesive tape feeding reel 121 for placing the plastic tape 16 and is positioned at the bottom of the adhesive tape feeding reel 121 for reclaiming the plastic tape. 16 tape recovery reel 126, the tape recovery reel 126 shaft is driven by a servo motor, a feeding transition rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com