Non-array type super-capacitive tactile sensor and application

A tactile sensor, super capacitor technology, applied in instruments, measuring devices, measuring force and other directions, can solve the problems of many leads, high signal-to-noise ratio, unable to solve the effective capacitance, etc., to increase the pressure detection range and high signal-to-noise ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

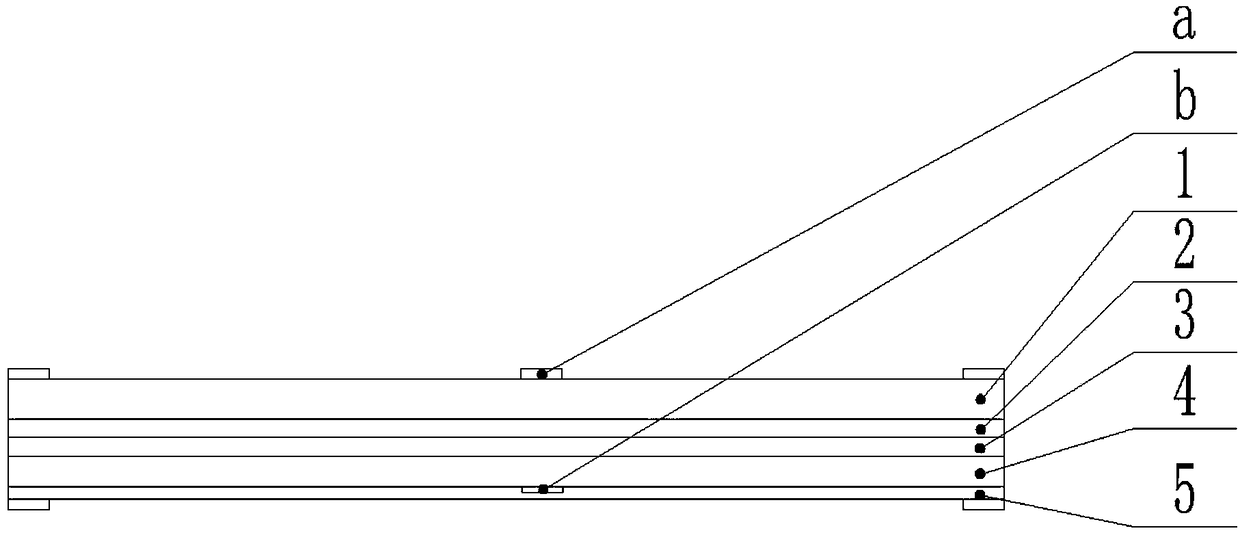

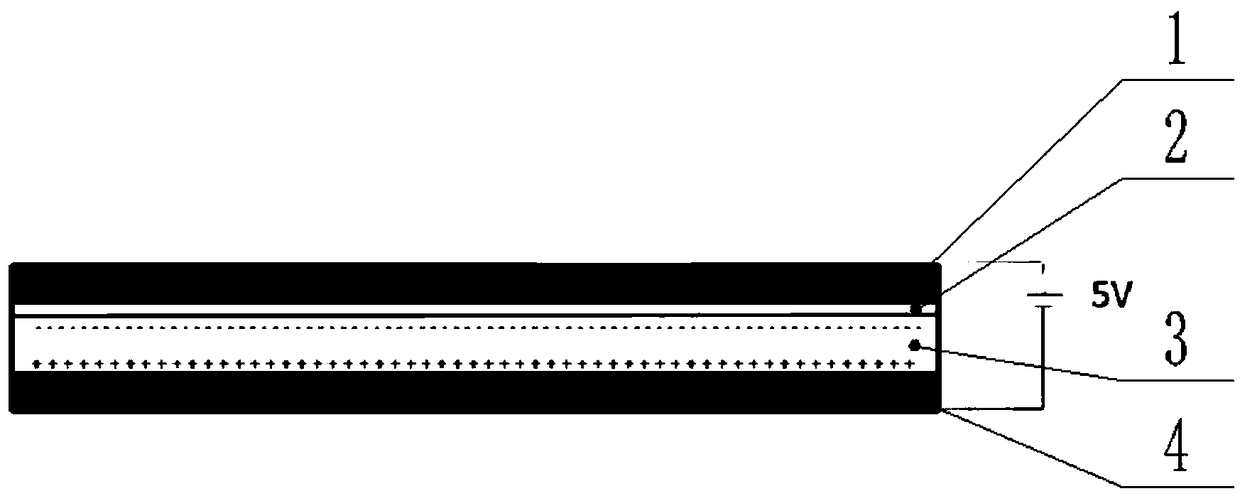

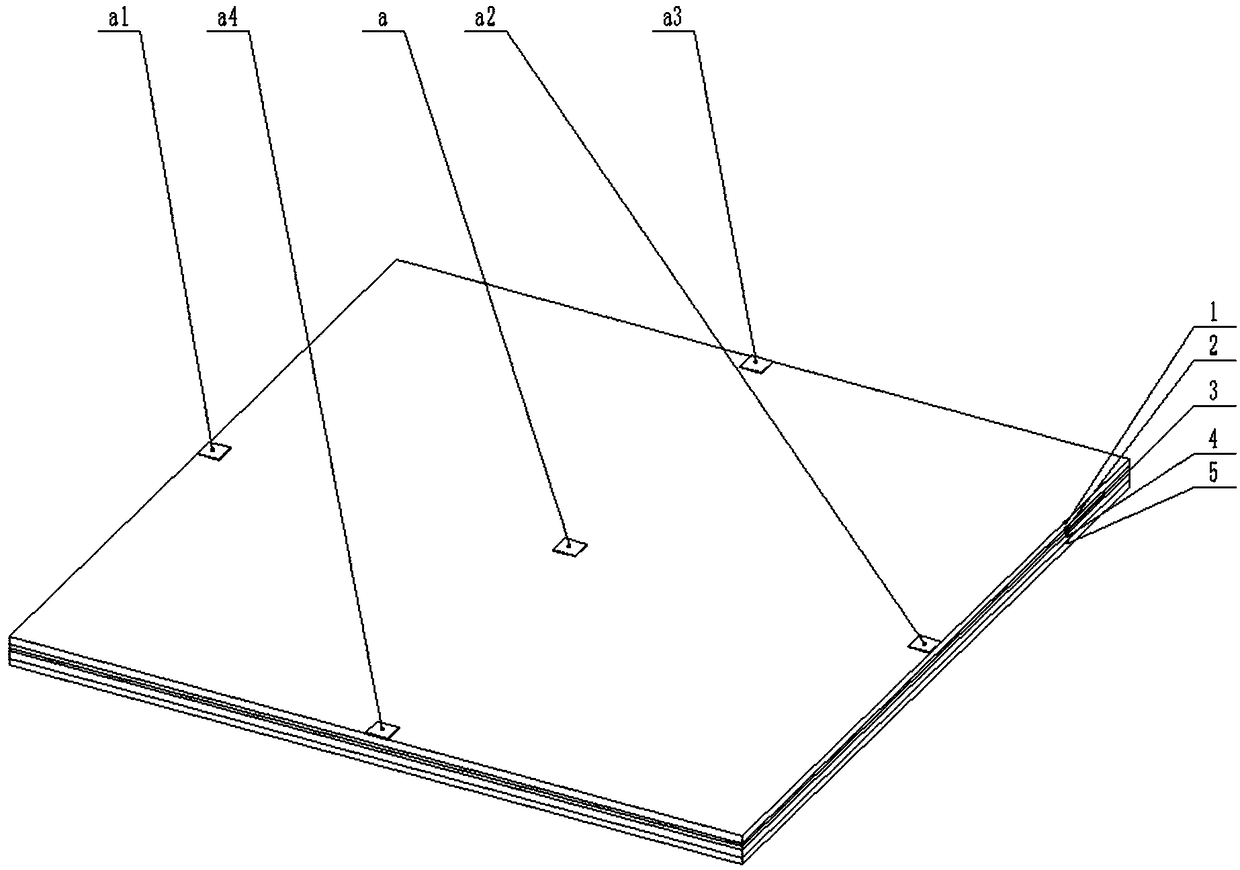

[0031] The non-array supercapacitive tactile sensor of this embodiment comprises an upper electrode layer 1, a lower electrode layer 4, a piezoelectric layer 5, and an ion gel layer 3 and an air layer 2 between the two electrode layers; the upper electrode layer Between the ion gel layer and the ion gel layer 3 is an air layer 2, the thickness of the ion gel layer is 300 μm, the resistance of the ion gel layer is greater than that of the upper electrode layer, and the ion gel layer can gather positive and negative electrodes on the upper and lower surfaces when electrified. Charge; the upper electrode layer is connected to the positive pole a of the power supply, the lower electrode layer is grounded b, and two sets of measuring electrodes are arranged along the horizontal and vertical directions on the upper surface of the upper electrode layer, and each set of measuring electrodes includes two measuring electrodes. The distance to the center of the upper electrode layer is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com