Quantum dot film with high luminous efficiency, and preparation process thereof

A high luminous efficiency, quantum dot film technology, applied in the direction of non-polymer adhesive additives, epoxy resin glue, adhesive type, etc., can solve the problems of low yield rate, poor stability of quantum dot film, etc., to achieve improved Stability, optimize the effect of curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

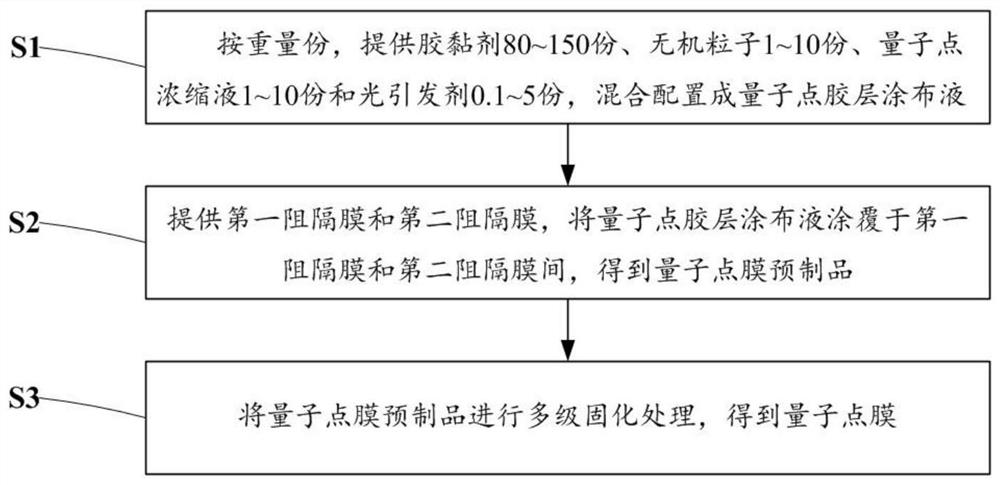

Method used

Image

Examples

Embodiment 1

[0043] (1) Mix 100 parts by weight of adhesive, 2.5 parts by weight of titanium dioxide particles, 0.5 parts by weight of benzophenone, 0.25 parts by weight of red quantum dot solution, and 1.75 parts by weight of green quantum dot solution to form quantum dots Adhesive coating solution.

[0044] (2) A first barrier film and a second barrier film are provided, and the quantum dot adhesive layer coating liquid is coated between the first barrier film and the second barrier film to obtain a quantum dot film pre-product.

[0045] (3) The quantum dot film pre-product is subjected to the first-stage curing treatment, the second-stage curing treatment and the third-stage curing treatment in sequence to obtain the quantum dot film.

Embodiment 2

[0047] Except that the above-mentioned quantum dot film pre-product is subjected to the first-stage curing treatment and the second-stage curing treatment in sequence, the rest is the same as that of Example 1.

Embodiment 3

[0049] (1) 100 parts by weight of adhesive, 2.5 parts by weight of titanium dioxide particles, 0.5 parts by weight of benzophenone, 0.8 parts by weight of 1-hydroxycyclohexyl phenyl ketone, 0.25 parts by weight of red quantum dot solution 1.75 parts by weight of the green quantum dot solution are mixed and configured to form a quantum dot glue layer coating solution.

[0050] (2) A first barrier film and a second barrier film are provided, and the quantum dot adhesive layer coating liquid is coated between the first barrier film and the second barrier film to obtain a quantum dot film pre-product.

[0051] (3) The quantum dot film pre-product is subjected to the first-stage curing treatment, the second-stage curing treatment and the third-stage curing treatment in sequence to obtain the quantum dot film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com