Strong release-type connecting adhesive tape

A strong release and adhesive tape technology, applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve the problems of poor release performance, high price, increased production costs, etc., to achieve strong release and durability Solvent, strong release properties, low migration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

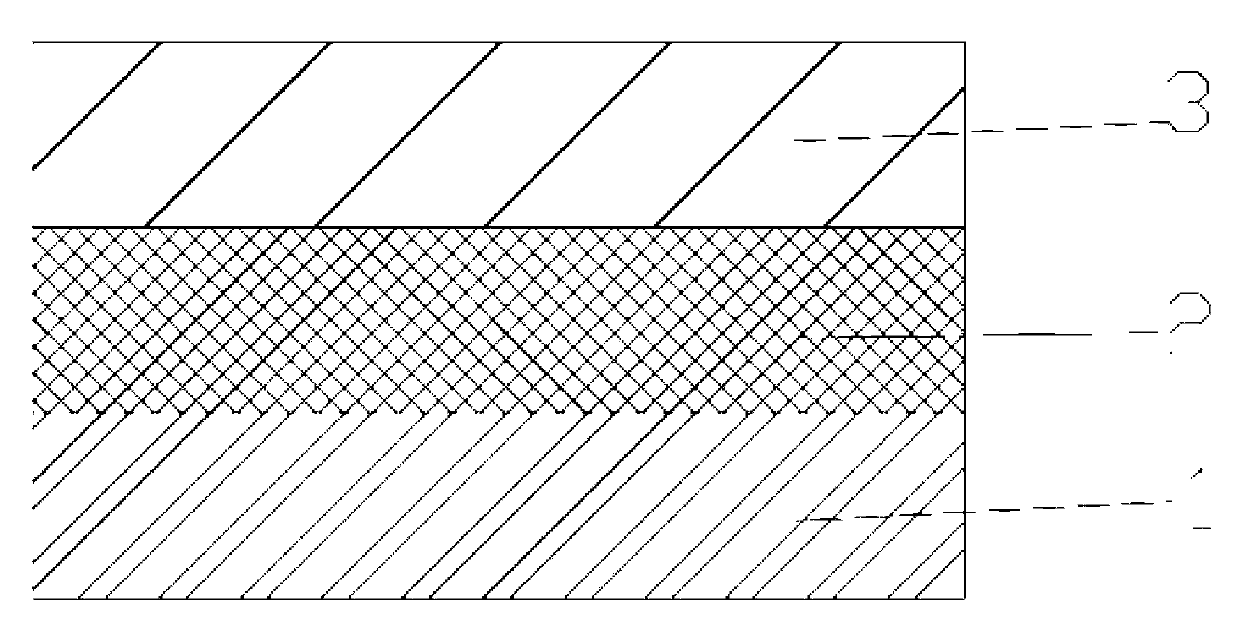

[0021] A strong release splicing adhesive tape, which comprises a layer of PET film 2, on one side of the PET film 2 is coated with a silica gel water layer 1, and on the other side is coated with a fluorine silicon coating 3.

[0022] The production process of the above-mentioned strong release splicing tape is as follows: use an anilox roller coating method, two-roll or three-roll transfer coating method, and apply a fluorine-silicon release agent on one side of the PET film 2 to form a fluorine-silicon coating 3. After standing at room temperature for one day, apply silica gel water on the other side of the PET film 2 by combining an anilox roller and a scraper to form a silica gel water layer 1 . During the preparation process, the cured fluorosilicone coating 3 can also be applied first, followed by the cured silica gel water layer 1, which can be completed online at one time.

[0023] In a preferred embodiment of the present invention, in the process of coating the fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com