Monomer of benzoxazine resin, benzoxazine resin and preparation method of benzoxazine resin

A benzoxazine and resin technology, applied in the field of bio-based thermosetting resin and its preparation, can solve the problems of unsatisfactory curing process, dependence on petroleum products, high curing temperature, and achieve the effects of low cost, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the low-temperature curing bio-based benzoxazine resin in this embodiment comprises the following steps:

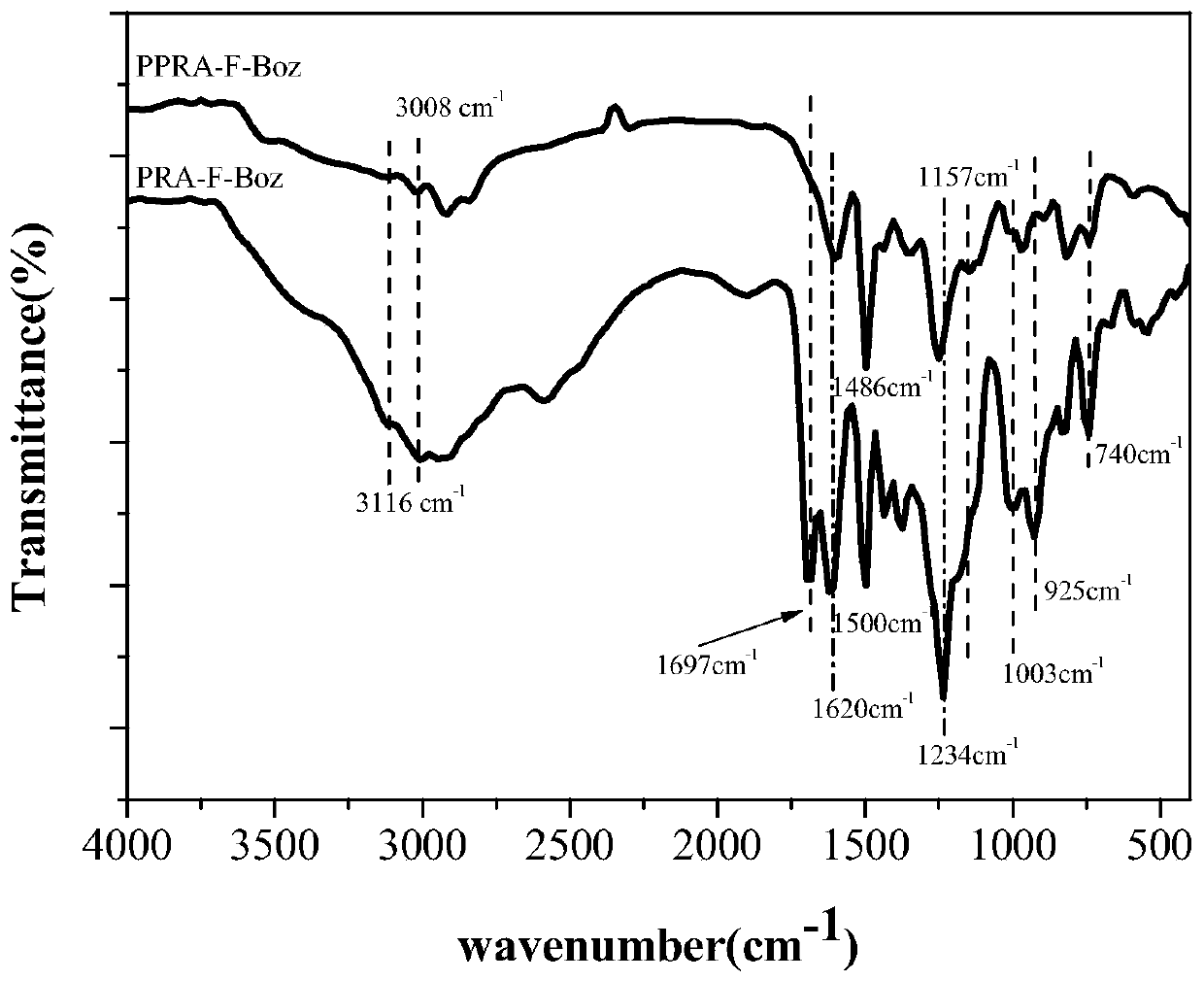

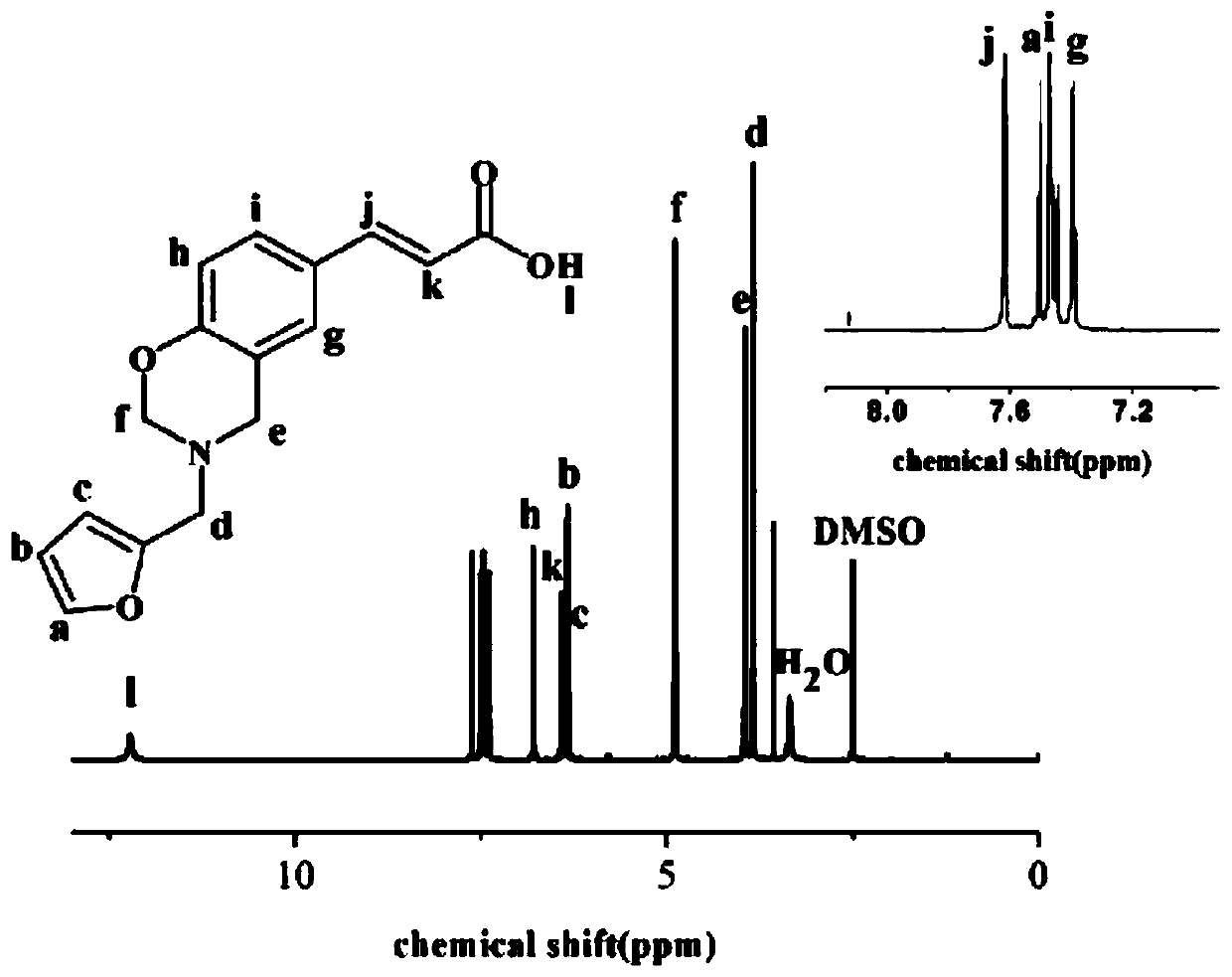

[0045] (1) In a three-neck round bottom flask equipped with a magnetic stirrer and a spherical condenser, add 0.01mol of p-coumaric acid, 0.02mol of furfurylamine, 0.02mol of polyoxymethylene and 100ml of dioxane in sequence, and stir until completely dissolved The temperature was slowly raised to a reflux state, and kept at the temperature of the reflux state for a constant temperature reaction for 8 hours. The obtained turbid solution was filtered to obtain a clear solution, cooled and crystallized in an ice-water bath to obtain a white powder, namely bio-based p-coumaric acid / furfurylamine type benzoxazine monomer (PRA-F-Boz), with a yield of 85.0% and a purity of 94.8% .

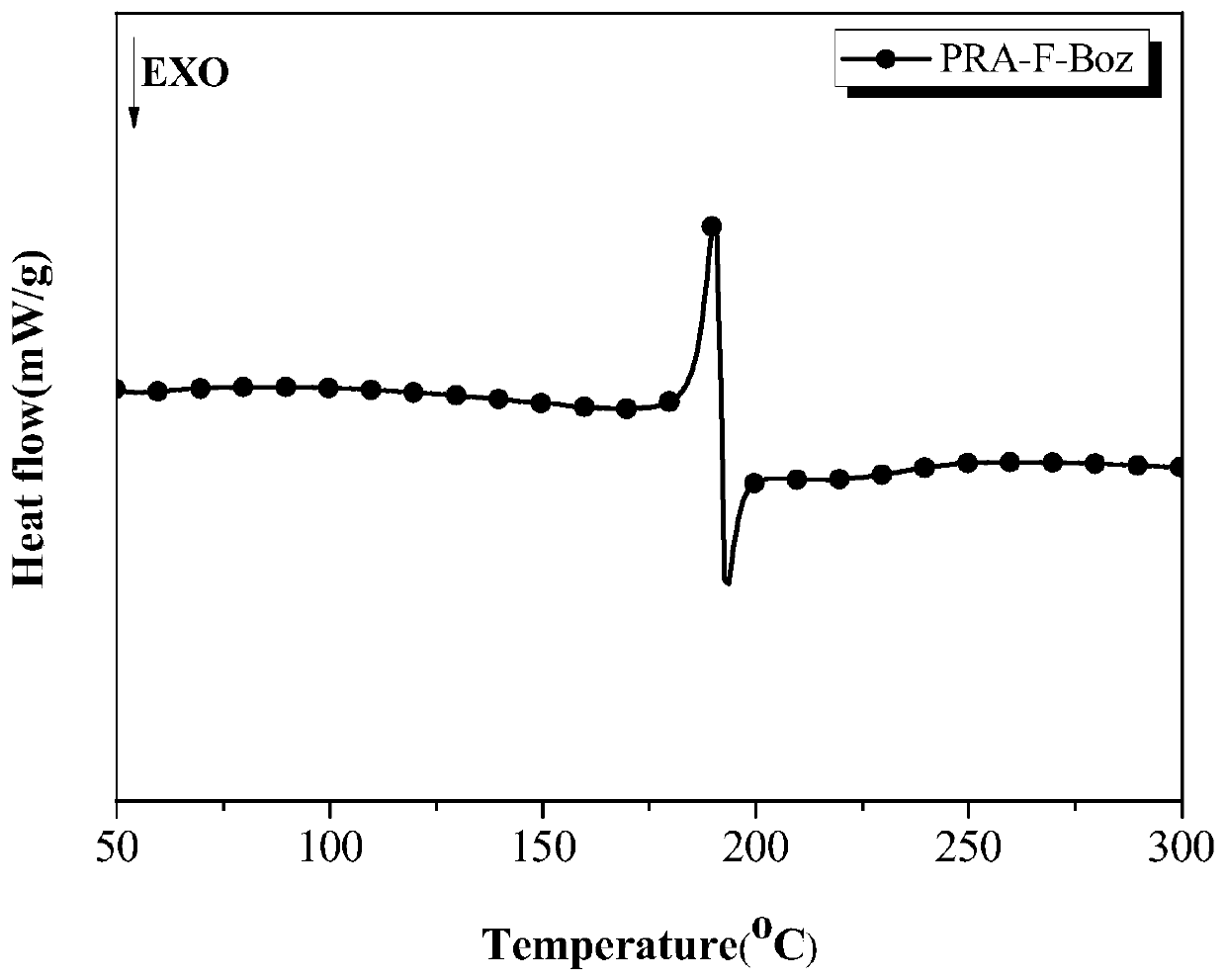

[0046] (2) Put the product of step (1) into the pre-prepared mold and put it in a blast drying oven for segmental curing. The heating process of segmental curing is...

Embodiment 2

[0048] The preparation method of the low-temperature curing bio-based benzoxazine resin in this embodiment comprises the following steps:

[0049] (1) In a three-neck round bottom flask equipped with a magnetic stirrer and a spherical condenser, add 0.01mol of p-coumaric acid, 0.01mol of furfurylamine, 0.02mol of polyoxymethylene and 100ml of dioxane in sequence, and stir until completely dissolved The temperature was slowly raised to a reflux state, and the reaction was carried out at a constant temperature for 6 hours. The resulting turbid solution was filtered to obtain a clear solution, cooled and crystallized in an ice-water bath to obtain a white powder, namely bio-based p-coumaric acid / furfurylamine benzoxazine monomer (PRA-F-Boz), with a yield of 75.0% and a purity of 91.8% .

[0050] (2) Put the product of step (1) into the pre-prepared mold and put it in a blast drying oven for segmental curing. The heating process of segmental curing is: 180°C / 1h, 185°C / 2h, 190°C / 1...

Embodiment 3

[0052] The preparation method of the low-temperature curing bio-based benzoxazine resin in this embodiment comprises the following steps:

[0053] (1) In a three-neck round bottom flask equipped with a magnetic stirrer and a spherical condenser, add 0.01mol of p-coumaric acid, 0.02mol of furfurylamine, 0.02mol of polyoxymethylene and 150ml of dioxane in sequence, and stir until completely dissolved The temperature was slowly raised to a reflux state, and the reaction was carried out at a constant temperature for 8 hours. The resulting turbid solution was filtered to obtain a clear solution, cooled and crystallized in an ice-water bath to obtain a white powder, namely bio-based p-coumaric acid / furfurylamine type benzoxazine monomer (PRA-F-Boz), with a yield of 94.0% and a purity of 97.8% .

[0054] (2) Put the product of step (1) into the pre-prepared mold and put it in a blast drying oven for segmental curing. The heating process of segmental curing is: 180°C / 1h, 185°C / 2h, 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com