Cylindrical wave strip-shaped coupler module

A technology of coupler and cylindrical wave, applied in the direction of frequency/direction characteristic device, etc., can solve the coupling effect of high frequency band of sound wave, improve sound quality and limited radiation transmission distance, sound radiation direct sound transmission distance limit, can not reach natural sound Coupling and other issues, to achieve the effect of high-precision sound energy coverage, high-definition analysis power, and long-distance sound wave radiation transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described in detail.

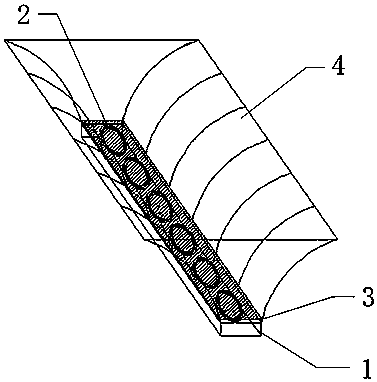

[0015] like figure 1 As shown, a cylindrical wave bar coupler module includes a bar-shaped NdFeB magnet 1, several voice coils 2, a bar-shaped diaphragm 3 and a horizontal control unit 4; the voice coil 2 is inlaid and mounted on The bar-shaped NdFeB magnet 1 is connected to the bar-shaped diaphragm 3, and the bar-shaped diaphragm 3 is fixed between the bar-shaped Nd-Fe-B magnet 1 and the horizontal control unit 4.

[0016] Further, the voice coil 2 is oval or circular.

[0017] Further, the strip-shaped diaphragm 3 is a strip-shaped composite diaphragm.

[0018] Further, the strip-shaped diaphragm 3 is adhered between the strip-shaped NdFeB magnet 1 and the horizontal control unit 4 by oxygen-insulated composite glue.

[0019] The present invention utilizes a plurality of vertically closely arranged voice coils embedded in the same bar-shaped NdFeB magnet to jointly push a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com