Monitoring and repairing method for curing and cementing of composite material

A composite material and curing glue technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as in-situ repairs that cannot be achieved, and achieve the effects of solving excessive local temperature differences, improving bonding strength, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

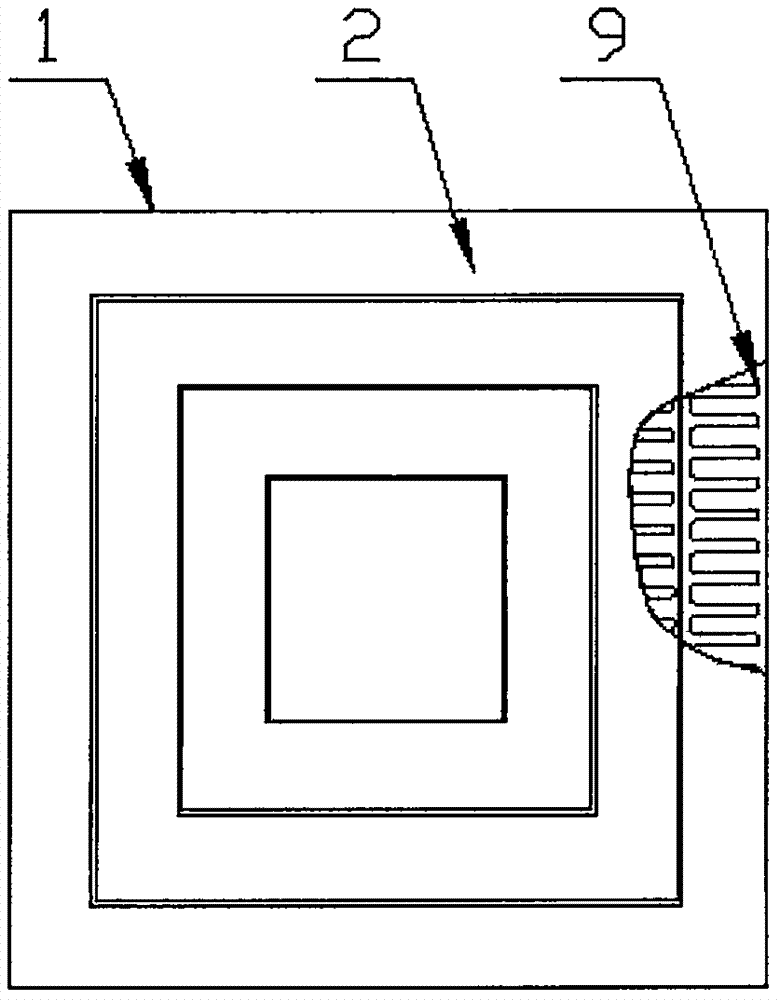

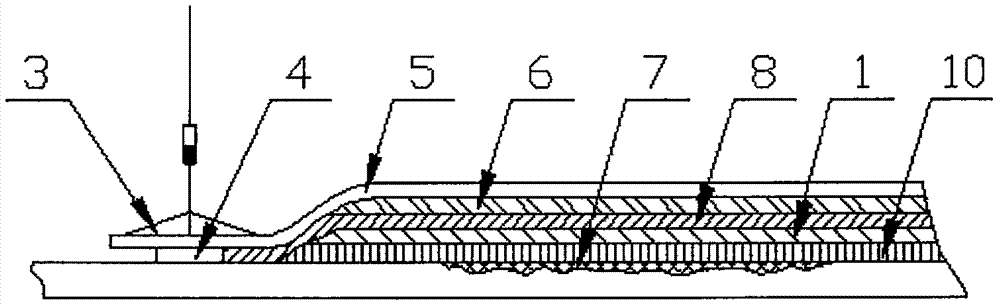

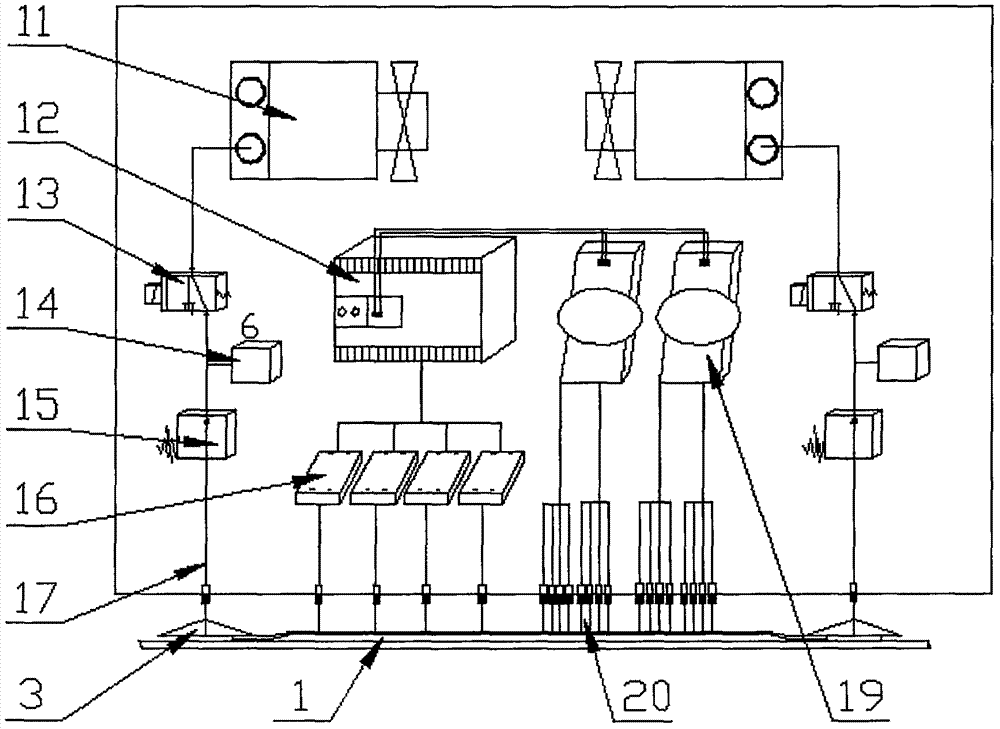

[0038] Attached below Figure 1-7 , a method for monitoring and repairing composite material solidified bonding of the present invention will be described in detail below.

[0039] 1Composite material curing adhesive repair equipment

[0040] 1.1 Mechanical structure of the equipment

[0041] as attached figure 1 As shown, a composite material curing adhesive repair equipment of the present invention includes a composite material prepreg 7 filled in the structurally damaged area, a curing source module 1 is arranged above the structurally damaged area, and the curing source The module 1 provides energy for the composite material prepreg 7 to be cured, and the curing source module 1 is surrounded by a plurality of temperature zones 2 from the inside to the outside, and each temperature zone 2 is provided with an independent The temperature zone 2 provides the energy curing source 9. Multiple temperature zones 2 are used alone or in conjunction with each other, and are determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com