High-toughness abrasion-resistant damping cable used for ships

A high-toughness technology for ships, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of restricting the execution of long-term maritime missions, increasing operating costs, frequent cable replacement, etc., to avoid gel failure, improve purity, The effect of nanoporous structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

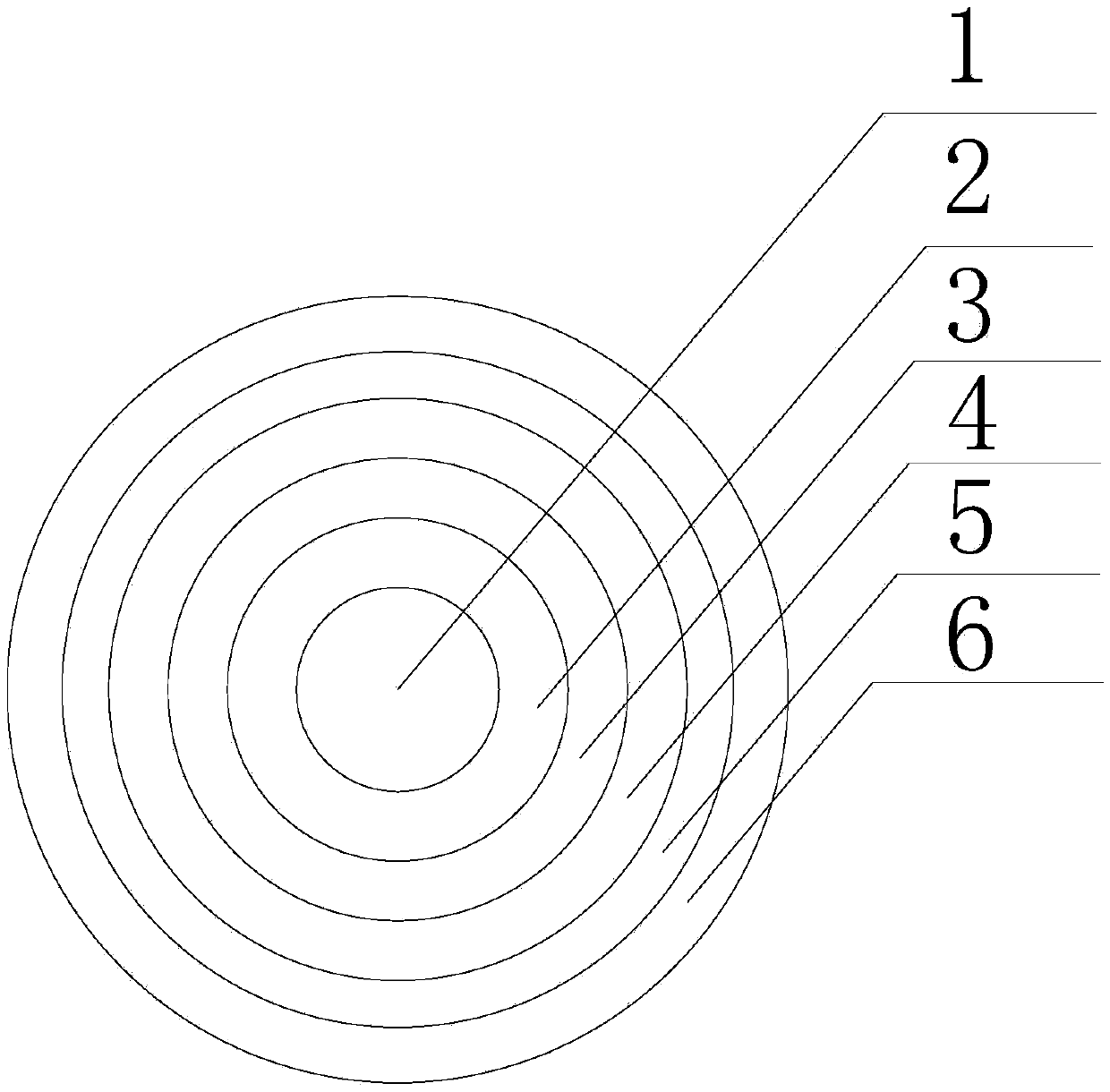

[0028] Such as figure 1 as shown, figure 1 It is a schematic diagram of the radial section structure of a high-toughness wear-resistant shock-absorbing cable for ships proposed by the present invention.

[0029] refer to figure 1 , a high-toughness wear-resistant shock-absorbing cable for ships proposed by the present invention includes a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, The armor layer 5 covering the shielding layer 4 and the outer sheath 6 covering the armor layer 5;

[0030]The raw materials of the outer sheath 6 include by weight: 60 parts of high cis-butadiene rubber, 20 parts of EPDM rubber, 18 parts of chlorinated polyethylene 140B, 8 parts of high toughness and high heat insulation performance gel, and 1.5 parts of sulfur powder 1.4 parts of accelerator DM, 2.4 parts of accelerator TMTM, 5 parts of trioctyl trimellitate, 3.5 parts of tribu...

Embodiment 2

[0036] A high-toughness wear-resistant shock-absorbing cable for ships proposed by the present invention comprises a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, a covering The armor layer 5 covering the shielding layer 4 and the outer sheath 6 covering the armor layer 5;

[0037] Wherein the raw material of outer sheath 6 comprises by weight: 50 parts of high cis-butadiene rubber, 25 parts of EPDM rubber, 15 parts of chlorinated polyethylene 140B, 12 parts of gel with high toughness and high heat insulation performance, 1 part of sulfur powder 11.7 parts of accelerator DM, 2.1 parts of accelerator TMTM, 7 parts of trioctyl trimellitate, 2 parts of tributyl citrate, 28 parts of barite powder, 17 parts of high wear-resistant carbon black, nanocarbonic acid 15 parts of calcium, 7 parts of superfine talcum powder, 9 parts of hard clay, 5 parts of kaolin, 4 parts of...

Embodiment 3

[0043] A high-toughness wear-resistant shock-absorbing cable for ships proposed by the present invention comprises a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, a covering The armor layer 5 covering the shielding layer 4 and the outer sheath 6 covering the armor layer 5;

[0044] The raw materials of the outer sheath 6 include by weight: 56 parts of high cis-butadiene rubber, 21 parts of EPDM rubber, 17 parts of chlorinated polyethylene 140B, 9 parts of high toughness and high heat insulation performance gel, and 1.4 parts of sulfur powder 1.5 parts of accelerator DM, 2.3 parts of accelerator TMTM, 5.5 parts of trioctyl trimellitate, 3.2 parts of tributyl citrate, 26 parts of barite powder, 19 parts of high wear-resistant carbon black, nanocarbonic acid 13 parts of calcium, 9 parts of superfine talcum powder, 7 parts of hard clay, 7 parts of kaolin, 2.5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com