High-efficiency water reducing agent and preparation method thereof

A high-efficiency water-reducing agent and water-reducing agent technology, applied in the field of water-reducing agents, can solve the problems of low production efficiency and easy mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

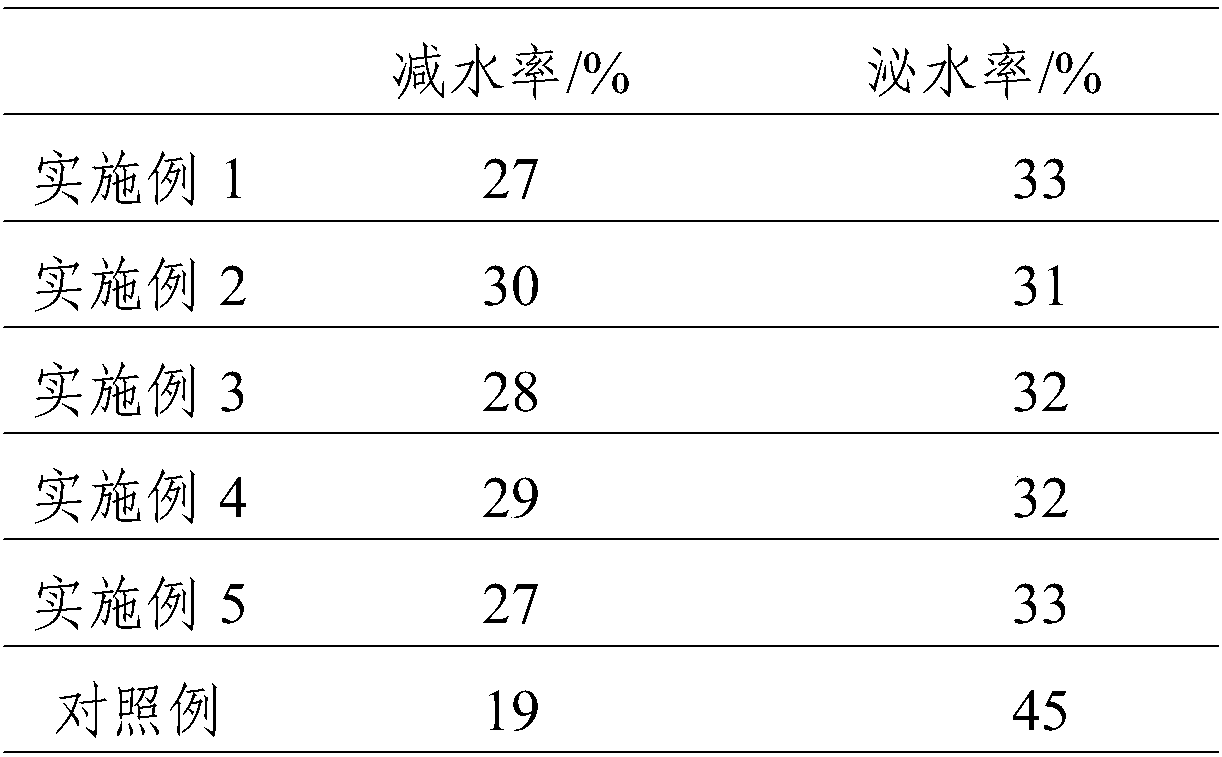

Embodiment 1

[0020] A high-efficiency water reducer, which is made of the following raw materials in parts by weight: 10 parts of naphthalene oil, 4 parts of liquid caustic soda, 15 parts of acetone, 5 parts of formaldehyde, 7 parts of potassium permanganate, 4 parts of sodium nitrite, Concentrated sulfuric acid 13 parts, appropriate amount of water.

[0021] The preparation method of this water reducer comprises the following steps:

[0022] (1) Add naphthalene oil and potassium permanganate into the reaction pot, heat and melt to 130°C, add concentrated sulfuric acid dropwise under the condition of mechanical stirring speed of 100r / min, and sulfonate for 2h;

[0023] (2) Cool the product obtained in step (1) to 120° C., add water equal in quality to naphthalene oil, and stir for 30 minutes to obtain a hydrolyzate;

[0024] (3) Add the hydrolyzed solution into the reactor, lower the temperature to 80° C., adjust the pressure to 2 MPa, add formaldehyde and acetone dropwise under the condi...

Embodiment 2

[0027] A high-efficiency water reducer, which is made of the following raw materials in parts by weight: 15 parts of naphthalene oil, 9 parts of liquid caustic soda, 20 parts of acetone, 11 parts of formaldehyde, 12 parts of potassium permanganate, 9 parts of sodium nitrite, Concentrated sulfuric acid 21 parts, appropriate amount of water.

[0028] The preparation method of this water reducer comprises the following steps:

[0029] (1) Add naphthalene oil and potassium permanganate into the reaction pot, heat and melt to 140°C, add concentrated sulfuric acid dropwise under the condition of mechanical stirring speed of 200r / min, and sulfonate for 2h;

[0030] (2) Cool the product obtained in step (1) to 125° C., add water equal in quality to naphthalene oil, and stir for 30 minutes to obtain a hydrolyzate;

[0031] (3) Add the hydrolyzed solution into the reactor, lower the temperature to 90° C., adjust the pressure to 2.5 MPa, add formaldehyde and acetone dropwise under the c...

Embodiment 3

[0034] A high-efficiency water reducer, which is made of the following raw materials in parts by weight: 11 parts of naphthalene oil, 5 parts of liquid caustic soda, 16 parts of acetone, 7 parts of formaldehyde, 8 parts of potassium permanganate, 6 parts of sodium nitrite, Concentrated sulfuric acid 10 parts, appropriate amount of water.

[0035] The preparation method of this water reducer comprises the following steps:

[0036] (1) Add naphthalene oil and potassium permanganate into the reaction pot, heat and melt to 135°C, add concentrated sulfuric acid dropwise under the condition of mechanical stirring speed of 120r / min, and sulfonate for 2h;

[0037] (2) Cool the product obtained in step (1) to 120° C., add water equal in quality to naphthalene oil, and stir for 30 minutes to obtain a hydrolyzate;

[0038] (3) Add the hydrolyzed solution into the reaction kettle, lower the temperature to 85° C., adjust the pressure to 2 MPa, add formaldehyde and acetone dropwise under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com