A process and device for recovering hydrochloric acid and producing copper sulfate from acidic etching waste liquid

A technology for recovering hydrochloric acid from acidic etching waste liquid, applied in copper sulfate, halogen/halogen acid, chemical instruments and methods, etc., can solve the problem of reducing the treatment cost of acidic etching waste liquid, low operating safety factor, low conversion rate of copper sulfate, etc. problems, achieve continuous and stable production, safe and stable operation, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

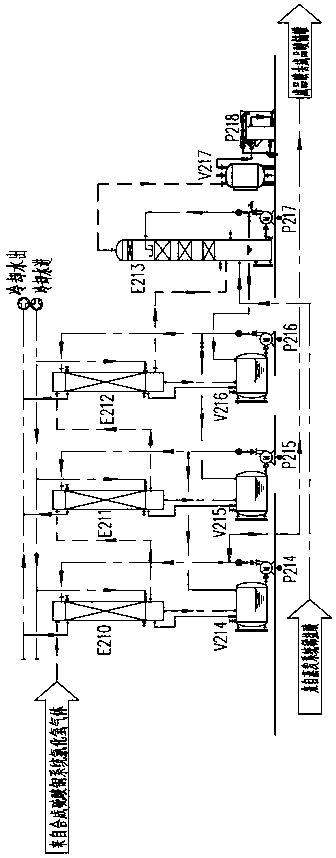

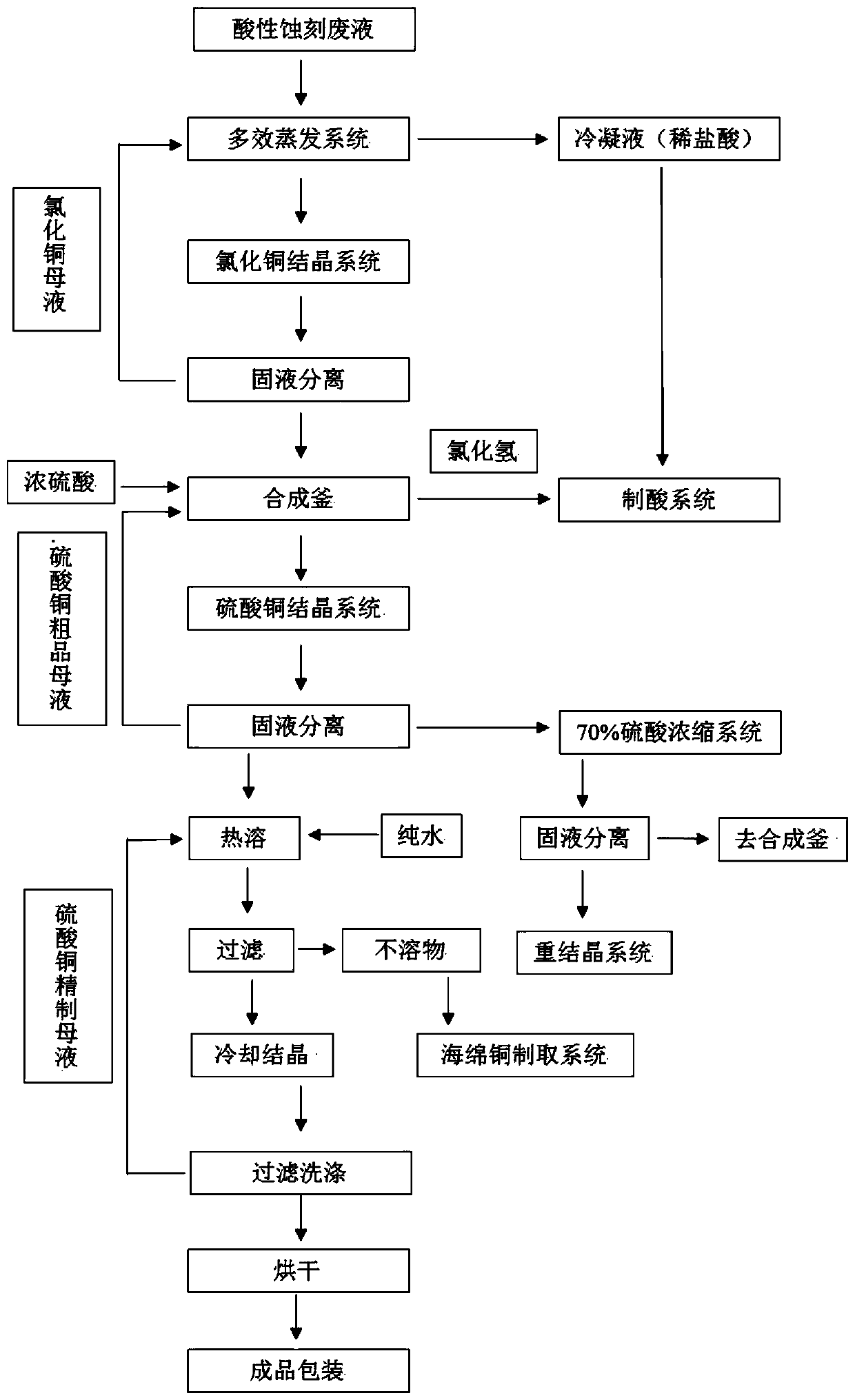

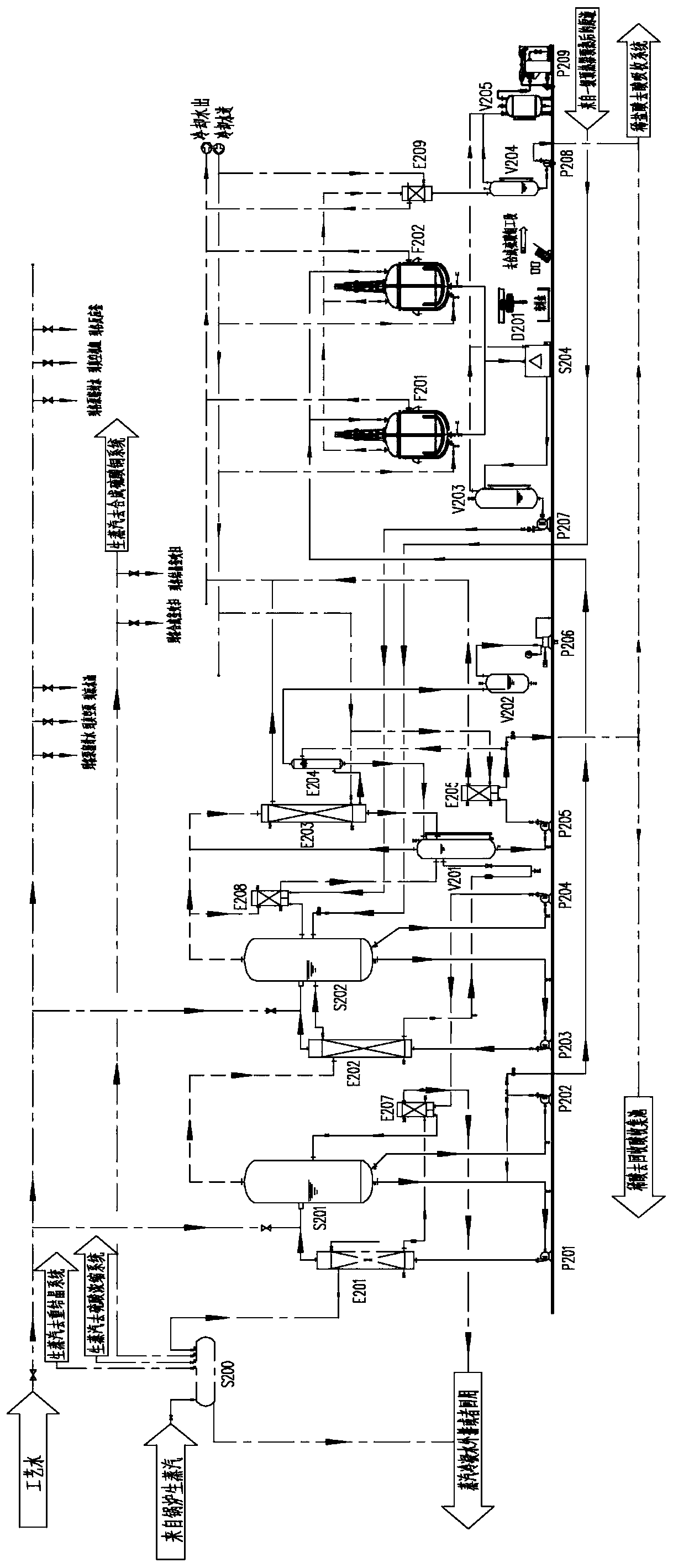

[0044] to combine figure 1 As shown, a kind of process of reclaiming hydrochloric acid and producing copper sulfate from acidic etching waste liquid of the present embodiment comprises the following steps:

[0045] (1) Pump the acidic etching waste liquid containing 10% copper ions and 10% hydrogen chloride into the multi-effect evaporation system after precipitation and removal of impurities, and produce dilute hydrochloric acid with a hydrogen chloride content of 12% to 14% as the recovery of high-concentration hydrochloric acid through evaporation and condensation The absorption solution of the acid system; the supersaturated concentrated solution of copper chloride produced by evaporation and concentration enters the copper chloride crystallization system, and after the crystallization is completed, the solid-liquid separation is carried out, and the separated copper chloride crystals enter the subsequent copper sulfate synthesis system. The separated copper chloride mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com