Separation method of oily sludge and application of sludge impurities to preparation of active carbon

A technology for preparing activated carbon and separation methods, which is applied in water/sludge/sewage treatment, sludge treatment, and pyrolysis sludge treatment, etc. Extraction and other problems, to avoid incomplete water-oil separation, improve the degree of water-oil separation, and promote the effect of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

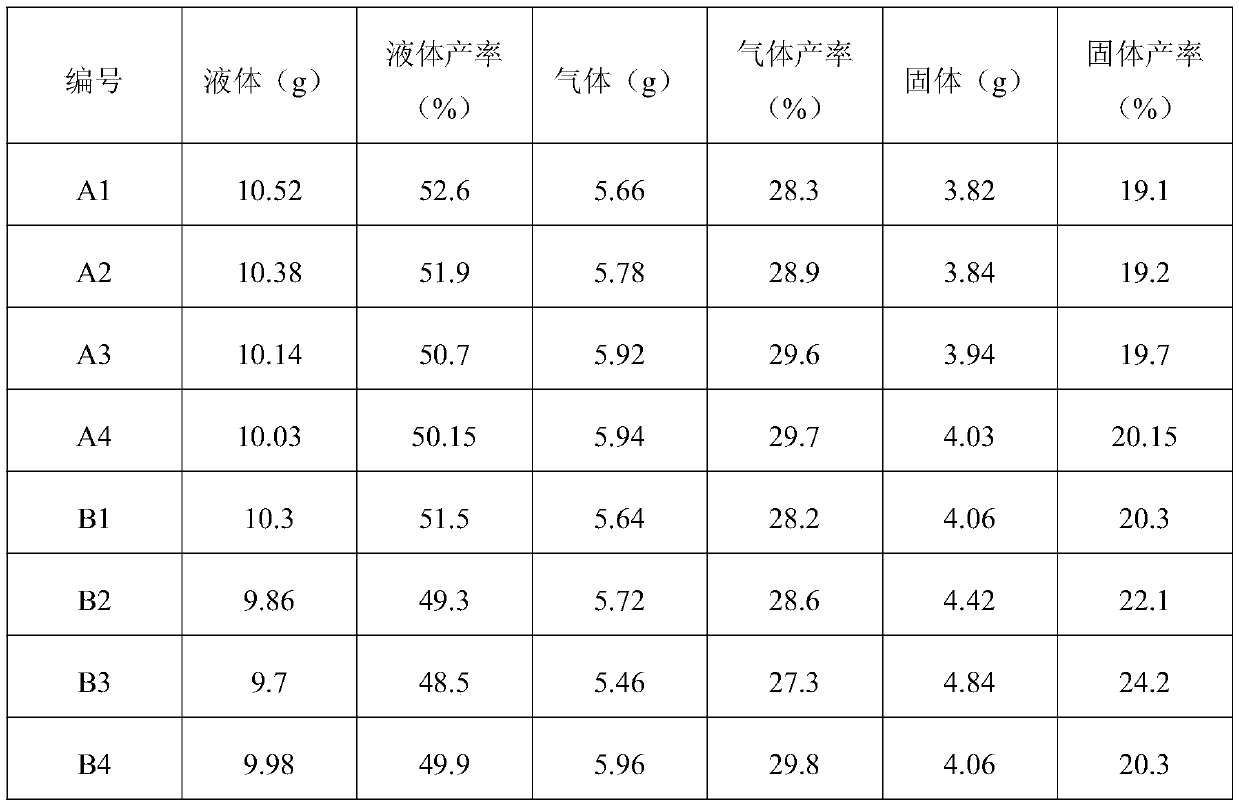

Embodiment 1

[0039] 1) Microwave the oily sludge for 2 minutes under microwave conditions with a frequency of 2500 MHz and an output power of 150 W; centrifuge the oily sludge after the above microwave treatment at a speed of 2000 r / min, and then place Place it under the condition of -15~-20℃ for 3-8 hours, add demulsifier to it, then place it under the condition of rotating speed of 4500r / min for a second centrifugation, and then remove the liquid phase to obtain the pretreated oily sludge;

[0040]2) Use nitrogen gas with a flow rate of 1L / min to purge the reactor to discharge the air in the reactor to form a nitrogen environment, and place the pretreated oily sludge in the above reactor at a heating rate of 20°C / min. Raise the temperature to 800°C, and then keep it warm for 10 minutes for dry distillation (during the dry distillation process, nitrogen gas is continuously fed at a flow rate of 100mL / min), and the gas phase and impurities after dry distillation are collected respectively, ...

Embodiment 2

[0042] 1) Microwave the oily sludge for 5 minutes under microwave conditions with a frequency of 2500 MHz and an output power of 150 W; centrifuge the oily sludge after the above microwave treatment at a speed of 2200 r / min, and then place it in Place it under the condition of -15~-20℃ for 3-8 hours, add demulsifier to it, then place it under the condition of rotating speed of 5500r / min for a second centrifugation, and then remove the liquid phase to obtain the pretreated oily sludge;

[0043] 2) Use nitrogen with a flow rate of 1L / min to purge the reactor to discharge the air in the reactor to form a nitrogen environment, and place the pretreated oily sludge in the above reactor at a heating rate of 40°C / min Raise the temperature to 900°C, and then keep it warm for 20 minutes to carry out dry distillation (during the dry distillation process, nitrogen gas is continuously fed at a flow rate of 100mL / min), and the gas phase and impurities after dry distillation are collected res...

Embodiment 3

[0045] Separation was carried out as in the separation method shown in Example 1, except that the microwave treatment time was 1 min, and the output power was 80 W, and the impurities in the gas phase and dry distillation were collected respectively, which were recorded as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com