Cross-linking agent for oil field produced water solution preparation and preparation method of cross-linking agent

A technology of cross-linking agent and produced water, which is applied in chemical instruments and methods, mining fluids, earthwork drilling and mining, etc. It can solve the problems of spatial network structure damage, decrease in the number of hydrophobic units, increase in apparent viscosity, etc., and achieve the goal of preparation process Simple, easy to obtain raw materials, strong salt resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention discloses a crosslinking agent for liquid preparation of oilfield produced water and a preparation method thereof. The crosslinking agent is composed of the following components in weight percent: sorbitol 8% to 15%, cationic polystyrene sulfonate 12% %-25%, solvent 10-20%, initiator 3-5%, catalyst 3%-5%, and the rest is water.

[0023] The specific operation steps of the preparation method of the crosslinking agent are as follows: add the sorbitol and the cationic polystyrene sulfonate of the formula quantity in the reactor, add the solvent and the initiator of the formula quantity simultaneously, and add the catalyst of the formula quantity, water Under vacuum conditions, stir and heat up to 180-190°C, react for 3-6 hours, and obtain a colorless and transparent liquid, which is the cross-linking agent for oilfield produced water.

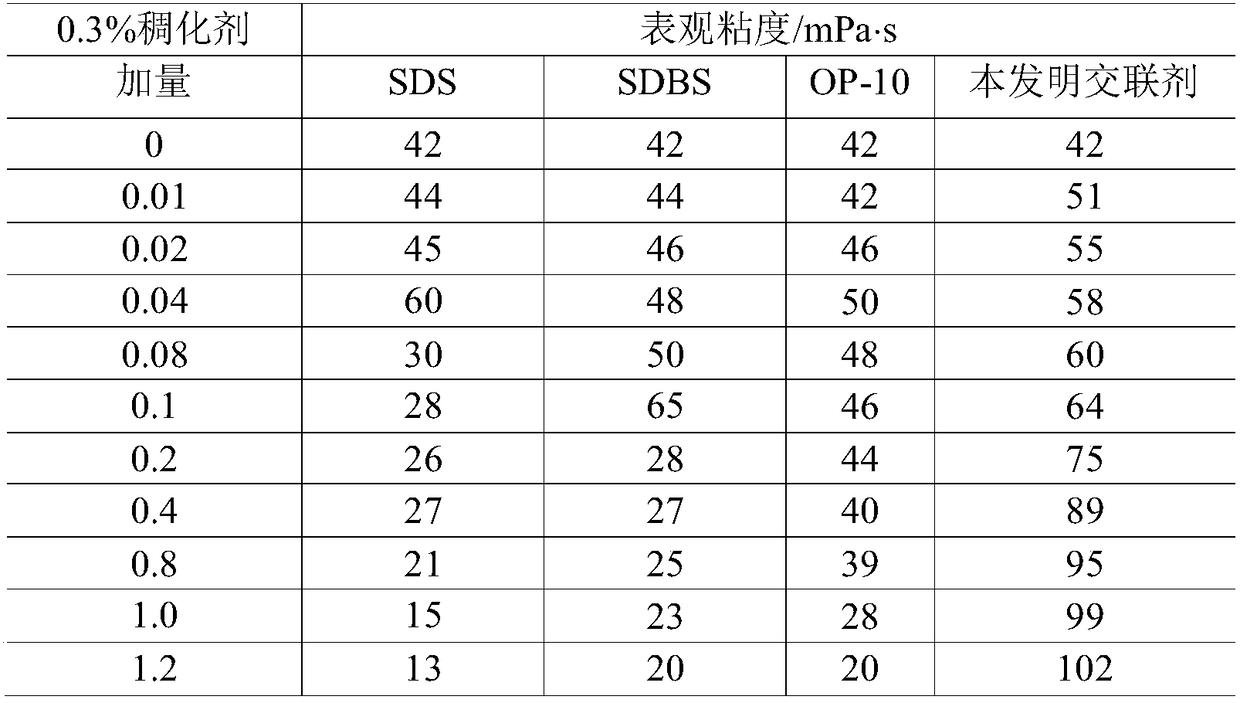

[0024] The cross-linking agent prepared by the invention has strong salt-resistant performance, and at the same time takes i...

Embodiment 2

[0026] On the basis of Example 1, sorbitol is used to react with cationic polystyrene sulfonic acid or polystyrene sulfonate, the ratio of the two substances is 1: (1.5~3.5), and 10-20% solvent is added at the same time And 3-5% initiator, add 3%-5% catalyst, under the condition of water vacuum, stir and heat up to 180-190°C, react for 3-6 hours, and obtain a colorless transparent liquid, which is oilfield produced water Cross-linking agent for solution.

[0027] The cationic polystyrene sulfonate is a light amber liquid with a molecular weight of 100,000-200,000; the cationic polystyrene sulfonate is polystyrene sulfonic acid, sodium polystyrene sulfonate, polystyrene One of the potassium sulfonates.

[0028] Described solvent is a kind of in methanol, ethylene glycol, ether, glycerol.

[0029] The initiator is one of ammonium persulfate, sodium persulfate and sodium perbromate.

[0030] The catalyst is one of sodium hydroxide, potassium hydroxide and sodium bicarbonate. ...

Embodiment 3

[0034] On the basis of the foregoing examples, a three-necked flask with magnetic stirring and a thermometer is placed on a magnetic stirrer temperature control electric heating mantle, and 8% sorbitol and 12% polystyrene sulfonic acid (sorbitol and The material ratio of polystyrene sulfonic acid is 1:1.5), while adding 10% methanol and 3% sodium persulfate, adding 3% sodium hydroxide, 64% water, stirring and heating up under the condition of water vacuum to 180°C, and continuously stirred for 6 hours to obtain a colorless transparent liquid, which is the cross-linking agent for oilfield produced water preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com