Method for preparing high-molecular-weight polylactic acid through direct condensation polymerization

A high-molecular-weight, polylactic acid technology, applied in the field of preparing high-molecular-weight polylactic acid, can solve the problems of high polylactic acid material price, high equipment requirements, complex process, etc., and achieve the effects of accelerating the lactic acid polycondensation reaction, low equipment requirements, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

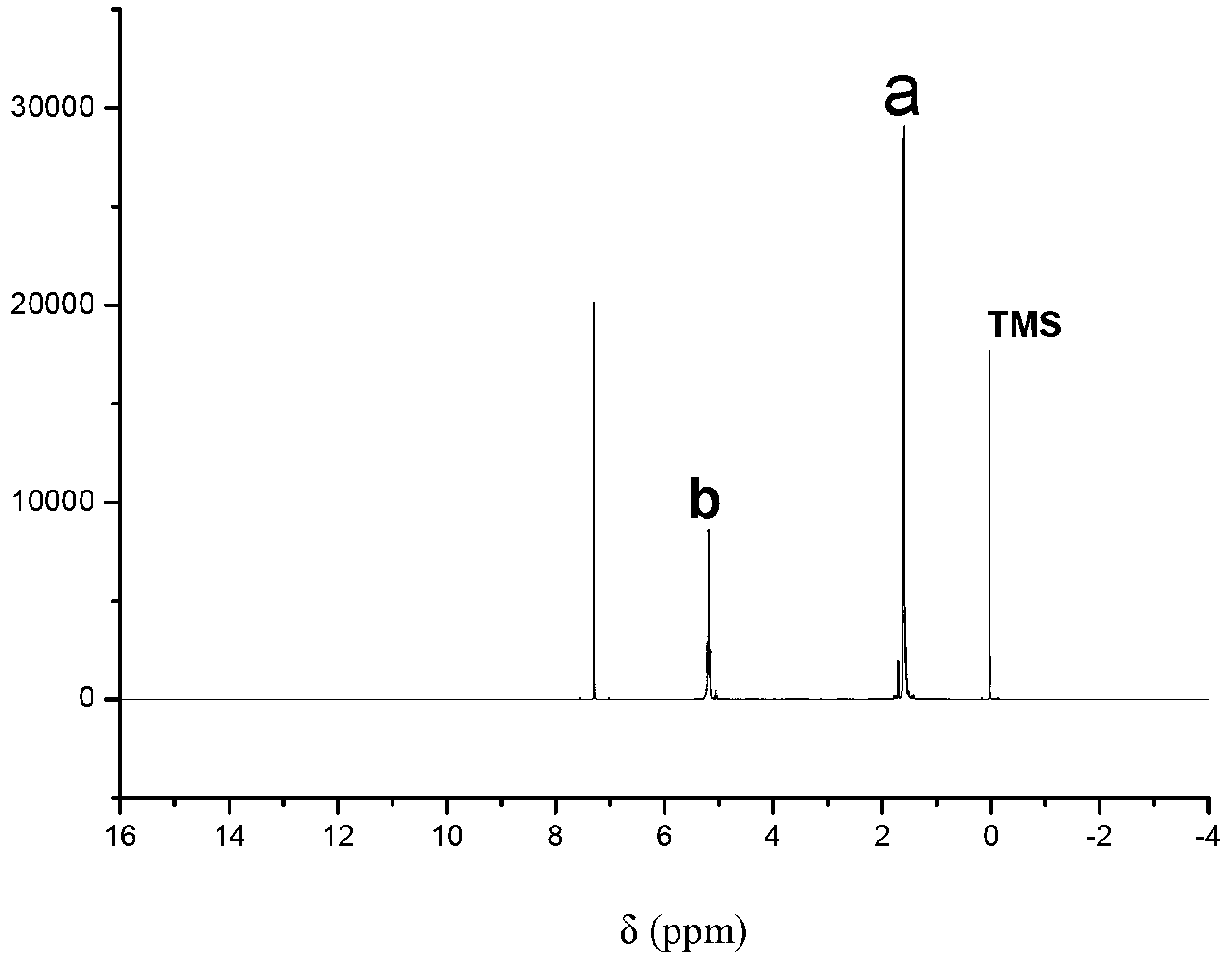

Image

Examples

Embodiment 1

[0024] 1) Mix 35g of lactic acid aqueous solution with a mass concentration of 85-90% (Tianjin Kemiou Chemical Reagent Co., Ltd.) and 10mL of toluene, and then rotate and dehydrate under reduced pressure at 65°C and a vacuum of 0.085MPa for 1h, that is Dehydrated lactic acid;

[0025] 2) Add dehydrated lactic acid into a 250mL three-neck flask, stir and raise the temperature to 100°C, then keep it warm for 10min under a vacuum of 0.065MPa, then drop the mixed solution of stannous octoate within 0.5h, keep it warm for 30min, stir and raise the temperature Temperature to 170°C and heat preservation for 5 hours under a vacuum of 0.095MPa to obtain a crude product, then purify, filter and dry the crude product to obtain a high molecular weight polylactic acid with a molecular weight of 60,000;

[0026] Among them, the mass of stannous octoate in the mixed solution of stannous octoate is 0.5% of the mass of dehydrated lactic acid, and the mixed solution of stannous octoate is compo...

Embodiment 2

[0028] 1) Mix 35g of lactic acid aqueous solution with a mass concentration of 85-90% (Tianjin Kemiou Chemical Reagent Co., Ltd.) and 10mL of toluene, and then rotate and dehydrate under reduced pressure at 65°C and a vacuum of 0.085MPa for 1h, that is Dehydrated lactic acid;

[0029] 2) Add dehydrated lactic acid into a 250mL three-necked flask, stir and raise the temperature to 90°C, keep it warm for 10min under a vacuum of 0.065MPa, then drop the mixed solution of stannous octoate within 0.5h, then keep it warm for 30min, stir and raise the temperature To 180°C and keep it under a vacuum of 0.095MPa for 5 hours to obtain a crude product, then purify, filter and dry the crude product to obtain a high molecular weight polylactic acid with a molecular weight of 80,000;

[0030] Among them, the mass of stannous octoate in the mixed solution of stannous octoate is 0.5% of the mass of dehydrated lactic acid, and the mixed solution of stannous octoate is composed of 0.15 g of stan...

Embodiment 3

[0033] 1) Mix 35g of lactic acid aqueous solution with a mass concentration of 85-90% (Tianjin Kemiou Chemical Reagent Co., Ltd.) and 10mL of toluene, and then rotate and dehydrate under reduced pressure at 65°C and a vacuum of 0.085MPa for 1h, that is Dehydrated lactic acid;

[0034] 2) Add dehydrated lactic acid into a 250mL three-necked flask, stir and heat up to 100°C, keep warm for 10min under a vacuum of 0.065MPa, then drop the mixed solution of stannous octoate within 0.5h, then keep warm for 30min, stir and heat up Heat at 190°C and keep it under a vacuum of 0.095MPa for 5 hours to obtain a crude product, then purify, filter and dry the crude product to obtain a high molecular weight polylactic acid with a molecular weight of 100,000;

[0035] Among them, the mass of stannous octoate in the mixed solution of stannous octoate is 0.5% of the mass of dehydrated lactic acid, and the mixed solution of stannous octoate is composed of 0.15 g of stannous octoate and 20 mL of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com