Method for cleaning type screw extrusion preparing of lithium battery polymer electrolyte membrane

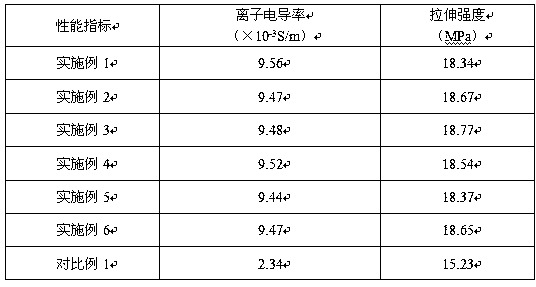

A technology of screw extrusion and electrolyte membrane, applied in electrolytes, secondary batteries, circuits, etc., can solve the problems of high cost, environmental pollution, unsatisfactory electrical conductivity and mechanical properties of solid electrolyte membranes, and achieve low cost, high electrical conductivity, etc. Good, process clean and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 56kg of polyvinylidene fluoride, 11kg of polyethylene oxide, 12kg of lithium hexafluorophosphate (LiPF 6 ), 7kg of pomegranate-type lanthanum-zirconium oxide electrolyte, 8kg of nano-titanium oxide, and 6kg of urea-plasticized cotton fibers were mixed, and then added to a vortex jet mill for interface modification and fine compounding under the impact of strong airflow. The spindle speed of the cyclone airflow pulverizer is 4300r / min, the strong air flow rate is 460m / s, and the time is 34min to prepare the compound; then 66kg compound and 34kg polyurethane elastomer are mixed evenly, and then the obtained mixed material is sent into In the twin-screw extruder, it is heated to a temperature of 70-90°C, and is continuously sheared and mixed at a speed of 300-500r / min to disperse evenly. The twin-screw extruder is equipped with a sheet die, and the mixture is passed through the die. The head is formed into a sheet, and then continuously stretched into thin sheets through r...

Embodiment 2

[0028] 60kg polyvinylidene fluoride, 9kg polyethylene oxide, 11kg lithium hexafluorophosphate (LiPF 6 ), 6kg Li 2 S-P 2 S 5 Sulfide electrolyte, 8kg nano-alumina, 6kg urea plasticized kapok fibers are mixed, then added to the vortex jet mill, and the interface is modified and refined under the impact of strong air flow. The spindle speed of the vortex jet mill is 4100r / min, the strong air flow rate is 420m / s, and the time is 38min to prepare the compound; then 62kg compound and 38kg polyester elastomer are mixed evenly, and then the obtained mixture is sent into the twin-screw extruder, Heat to a temperature of 75°C, and carry out continuous shear mixing at a speed of 350r / min to disperse evenly. The twin-screw extruder is equipped with a sheet die, and the mixed material is formed into a sheet through the die, and then continuously passed through roller calendering and stretching Form into thin sheets, the roller temperature of roller calendering is 42 ℃, the roller speed ...

Embodiment 3

[0031] 54kg of polyvinylidene fluoride, 11kg of polyethylene oxide, 13kg of lithium hexafluorophosphate (LiPF 6 ), 7kg of pomegranate-type lanthanum-zirconium oxide electrolyte, 9kg of nano-zinc oxide, and 7kg of urea-plasticized flax fiber were mixed, and then added to a vortex airflow mill for interface modification and fine compounding under the impact of strong airflow. The rotational speed of the main shaft of the cyclone airflow pulverizer is 4400r / min, the strong air flow rate is 480m / s, and the time is 33min to prepare the compound; then 68kg of the compound and 32kg of polyurethane elastomer are mixed evenly, and then the obtained mixed material is sent into In the twin-screw extruder, heat it to a temperature of 85°C, and carry out continuous shearing and mixing at a speed of 450r / min to disperse evenly. The twin-screw extruder is equipped with a sheet die, and the mixed material is formed into a sheet through the die. Then it is stretched into thin sheets by roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com