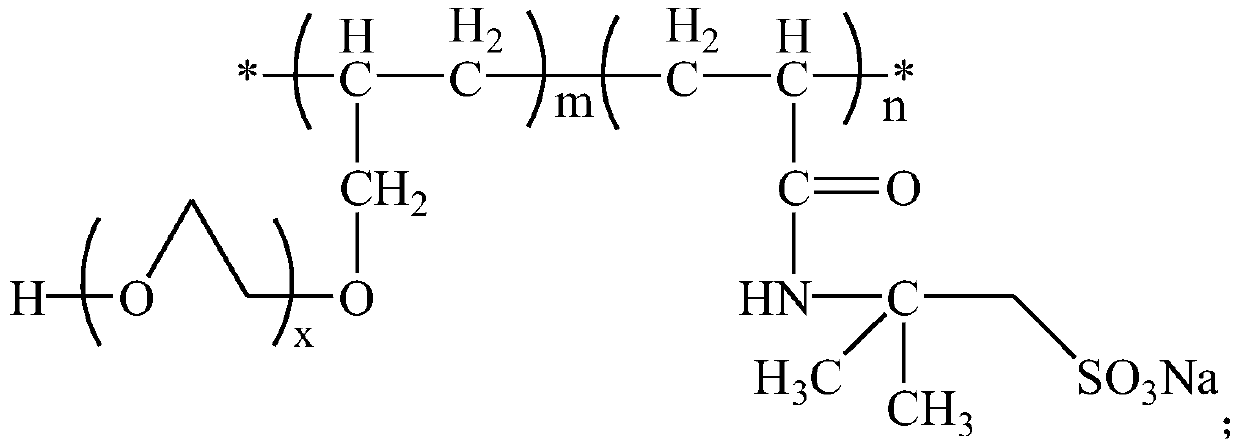

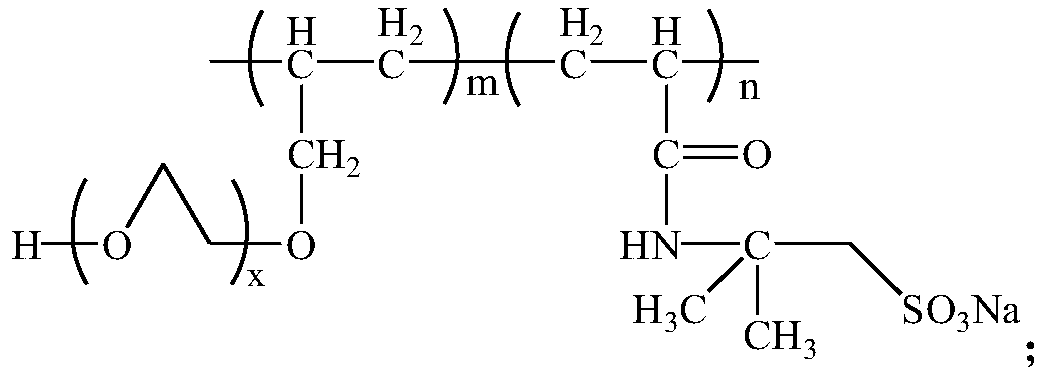

Permeable modified viscosity-reducing oil-displacing agent for water drive thickened oil as well as preparation method of oil-displacing agent

An oil-displacing agent and modification technology, applied in the field of chemical agents, can solve the problems of difficult viscosity-lowering agent efficiency, large oil-water mobility ratio, etc., and achieve the effects of clean process, no pollution, reduced use concentration, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

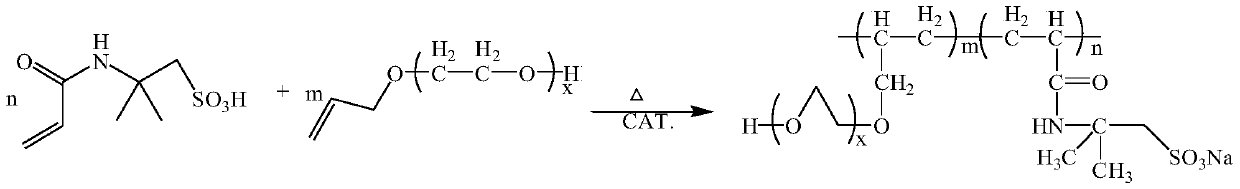

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 1 mol of 2-acrylamide-2-methylpropanesulfonic acid and 0.1 mol of allyl alcohol polyoxyethylene ether into a four-necked flask with a thermometer, reflux condenser, and stirrer, and heat while stirring , The stirring rate is 200 rpm, the heating temperature is 30°C, and the nitrogen is introduced for 5 minutes.

[0029] (2) Then add 0.88g sodium bisulfite and 0.88g ammonium persulfate solution, continue to pass nitrogen, raise the heating temperature of the four-neck flask to 70℃, adjust the stirring rate to 500rpm, and turn off the heat source and stirrer after 4 hours of reaction. After cooling to room temperature, pour it into a beaker to obtain a crude product.

[0030] (3) Wash the above-mentioned crude product with 1362.2g of absolute ethanol for 3 times, and then place it in an oven at 60°C for 24 hours to obtain a white solid material, which is crushed and sieved with a pulverizer to obtain a white powder with a mesh number of 300-500, namely Permeable modif...

Embodiment 2

[0037] (1) Add 1 mol of 2-acrylamide-2-methylpropanesulfonic acid and 1.5 mol of allyl alcohol polyoxyethylene ether into a four-neck flask with a thermometer, reflux condenser, and stirrer, and heat while stirring , The stirring rate is 300 rpm, the heating temperature is 45°C, the nitrogen is introduced, and the nitrogen is introduced for 6 minutes.

[0038] (2) Then add 0.80g sodium bisulfite and 0.88g ammonium persulfate solution, continue to pass in nitrogen, raise the heating temperature of the four-neck flask to 75℃, adjust the stirring rate to 520rpm, and turn off the heat source and stirrer after 6 hours of reaction. After cooling to room temperature, pour it into a beaker to obtain a crude product.

[0039] (3) Wash the above crude product 4 times with 1486.3g of absolute ethanol, and then place it in an oven at 65°C for 26 hours to obtain a white solid material, which is crushed and sieved with a pulverizer to obtain a white powder with a mesh number of 300-500, namely ...

Embodiment 3

[0046] (1) Add 1 mol of 2-acrylamide-2-methylpropanesulfonic acid and 4.8 mol of allyl alcohol polyoxyethylene ether into a four-necked flask with a thermometer, reflux condenser, and stirrer, and heat while stirring , The stirring rate is 350 rpm, the heating temperature is 52 ℃, nitrogen is introduced, and the time of nitrogen is 7 minutes.

[0047] (2) Then add 1.2g sodium bisulfite and 1.42g ammonium persulfate solution, continue to pass in nitrogen, raise the heating temperature of the four-neck flask to 80°C, adjust the stirring rate to 560rpm, and turn off the heat source and stirrer after reacting for 5 hours. After cooling to room temperature, pour it into a beaker to obtain a crude product.

[0048] (3) Wash the above crude product 5 times with 1568.7g of absolute ethanol, and then place it in an oven at 73°C for 25h to obtain a white solid material, which is crushed and sieved with a pulverizer to obtain a white powder with a mesh number of 300-500, namely Permeable mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com