Separation, purification and recovery process of hydrogen in industrial waste gas

A technology for industrial waste gas and hydrogen, which is applied in hydrogen separation, separation of hydrogen using solid contact, separation of hydrogen by selective and reversible absorption, etc. problems, to achieve the effect of low comprehensive use cost, increased turbulence effect, and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

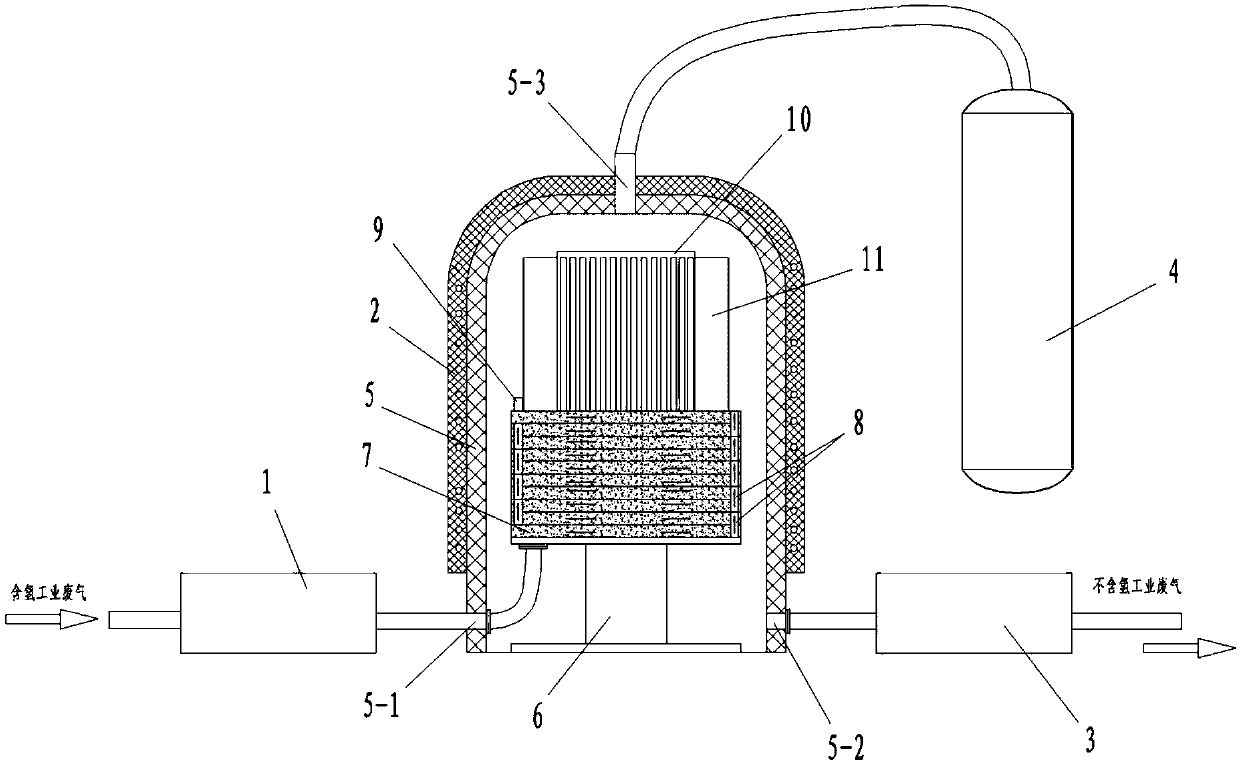

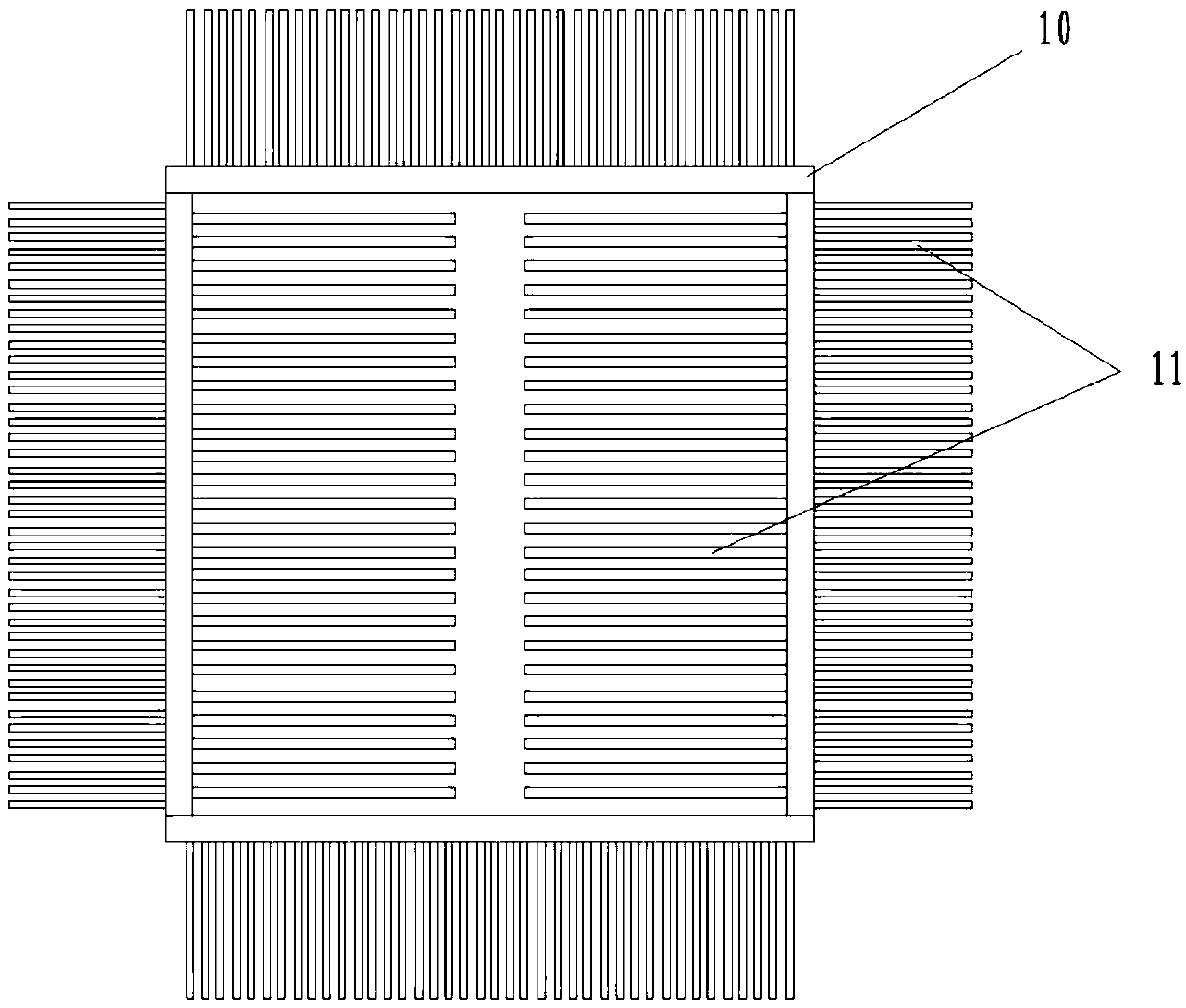

[0020] See attached figure 1 and 2 , the process of the present invention is based on an industrial waste hydrogen separation, purification and recovery system, which includes a waste gas pressurization device 1, a hydrogen storage alloy container, a hydrogen storage alloy container heating device 2, an exhaust device 3, a hydrogen storage device, a recovery device 4 and supporting pipeline.

[0021] The waste gas boosting device 1 mentioned above is a booster pump, which is used to fill the hydrogen storage alloy container with industrial waste gas containing hydrogen.

[0022] The above-mentioned hydrogen storage alloy container heating device 2 includes a heating wire arranged outside the hydrogen storage alloy container for heating and raising the temperature of the hydrogen storage alloy container.

[0023] The above-mentioned hydrogen storage alloy container includes a housing 5 having an air inlet 5-1, an exhaust port 5-2 and a hydrogen outlet 5-3, and a hydrogen stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com