Low-temperature methanol washing device and method for removing acid gas in synthesis gas

A low-temperature methanol washing and methanol technology, which is applied in hydrogen/synthesis gas production, low-temperature hydrogen separation, climate sustainability, etc., can solve the problems of methanol loss, high energy consumption, and prone to ammonia crystallization, etc., to reduce consumption and reduce Methanol loss, effects of avoiding ammonia crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

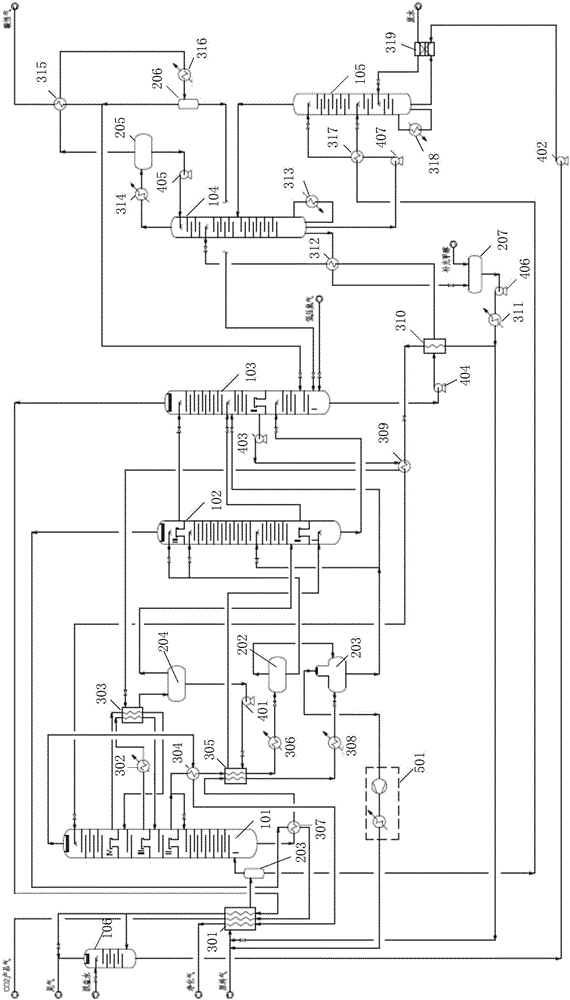

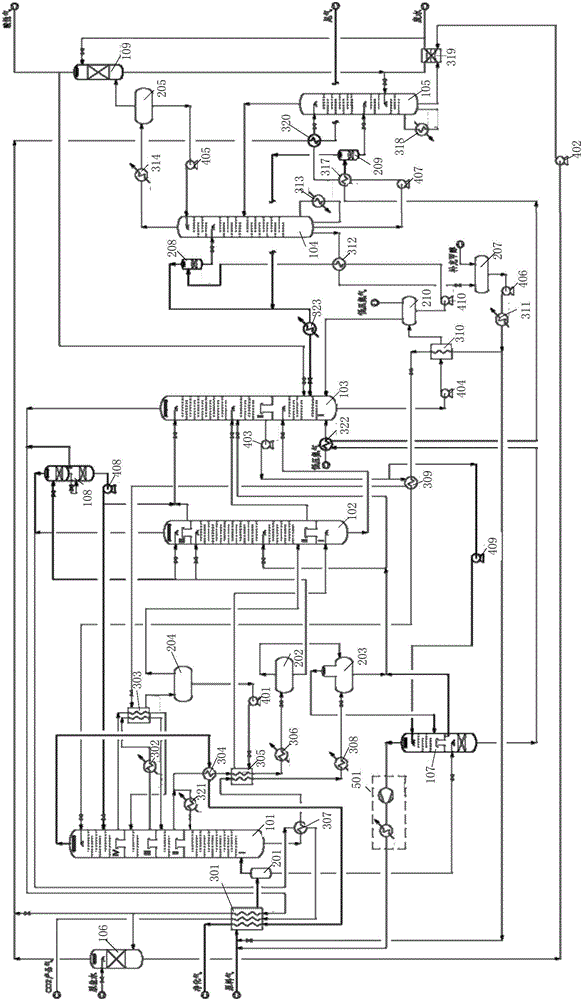

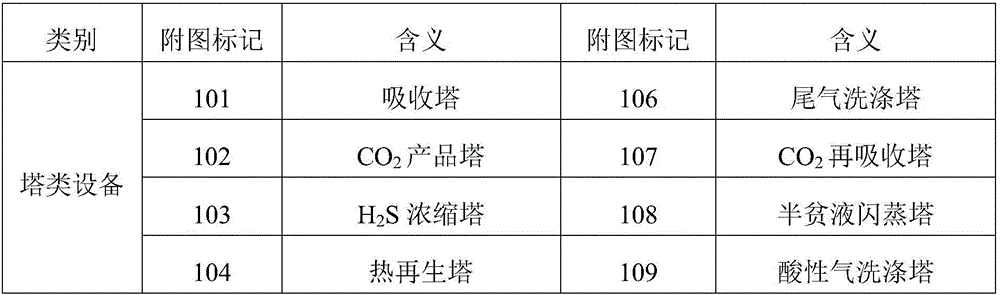

[0047] Embodiment 1 adopts such as figure 2 process shown.

[0048] The feed gas from the upstream conversion unit is mixed with methanol from the methanol-lean water cooler 311 and the recycle gas from the recycle gas compressor 501, and then cooled to -11~-25°C through the feed gas cooler 301. The cooled raw gas enters the raw gas separator 201 for flash separation.

[0049] The absorption tower 101 is divided into four sections of I, II, III, and IV from bottom to top. Section I at the bottom and Section IV at the top. Section I of the absorption tower 101 is a desulfurization section, and sections II to IV of the absorption tower 101 are decarburization sections. The gas phase separated by the feed gas separator 201 enters the bottom of the first section of the absorption tower 101. The top of the first section of the absorption tower 101 uses part of the sulfur-free methanol-rich solution from the second section of the absorption tower 101 as an absorbent. The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com