Hydrogen-containing tail gas recycling process of cyclohexanol production device

A production device and tail gas recovery technology, which is applied in hydrogen separation, low-temperature hydrogen separation, hydrogen separation using solid contact, etc., can solve the problems of large hydrogen consumption, high hydrogen production cost, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

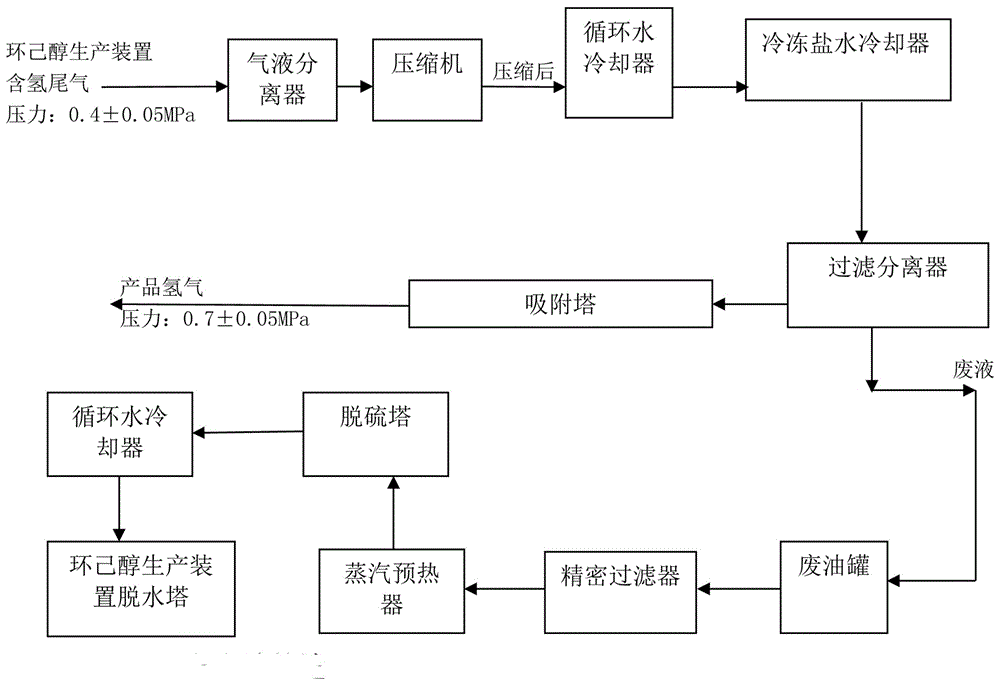

[0009] A process for recycling hydrogen-containing tail gas of a cyclohexanol production device, comprising the following steps: sending the hydrogen-containing tail gas (0.40MPa, ≤40°C) generated by the cyclohexanol production device into a gas-liquid separator, and separating the mechanical liquid therein The gas separated by the gas-liquid separator is compressed to 0.8MPa by the compressor, cooled to 40°C by the circulating water cooler, and then cooled to 8°C by the frozen brine cooler (at this temperature, it can be separated by the filter separator A large amount of impurities such as cyclohexene, cyclohexane and benzene), and finally enter the filter separator to obtain waste liquid and crude hydrogen (at this time, there are traces of cyclohexene, cyclohexane, benzene and other impurity components in the crude hydrogen), The crude hydrogen is removed through the adsorption tower to remove trace impurities such as cyclohexene, cyclohexane, benzene, etc., to obtain the p...

Embodiment 2

[0013] The difference between Example 2 and Example 1 is that the gas separated by the gas-liquid separator is compressed to 0.7 MPa by the compressor, cooled to 45°C by the circulating water cooler, and then cooled to 12°C by the refrigerated brine heat exchanger; After the organic phase is filtered through a precision filter, the temperature is raised to 140°C through a medium-pressure steam preheater.

Embodiment 3

[0015] The difference between Example 3 and Example 1 is that the gas separated by the gas-liquid separator is compressed to 0.7 MPa by the compressor, cooled to 42°C by the circulating water cooler, and then cooled to 10°C by the refrigerated brine heat exchanger; After the organic phase is filtered through a precision filter, the temperature is raised to 130°C through a medium-pressure steam preheater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com