Nanometer magnesium hydride hydrogen-storage material preparation method

A hydrogen storage material, a technology of magnesium hydride, applied in the directions of alkali metal/alkaline earth metal/beryllium/magnesium hydride, hydrogen separation, hydrogen separation by selective and reversible absorption, etc. The problems of large grain size and low hydrogen storage capacity can solve the problems of harsh preparation conditions, low equipment requirements and low operating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

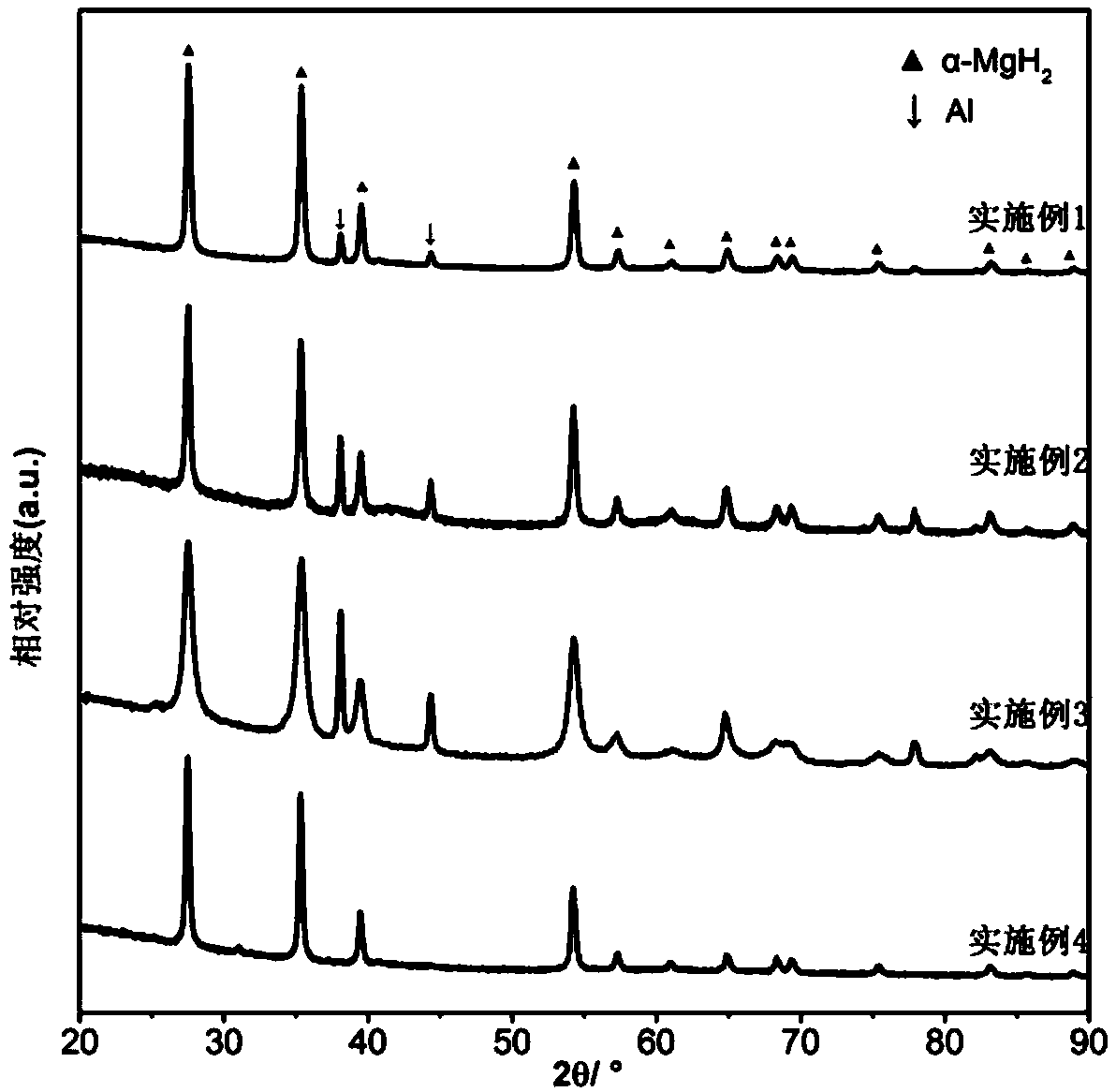

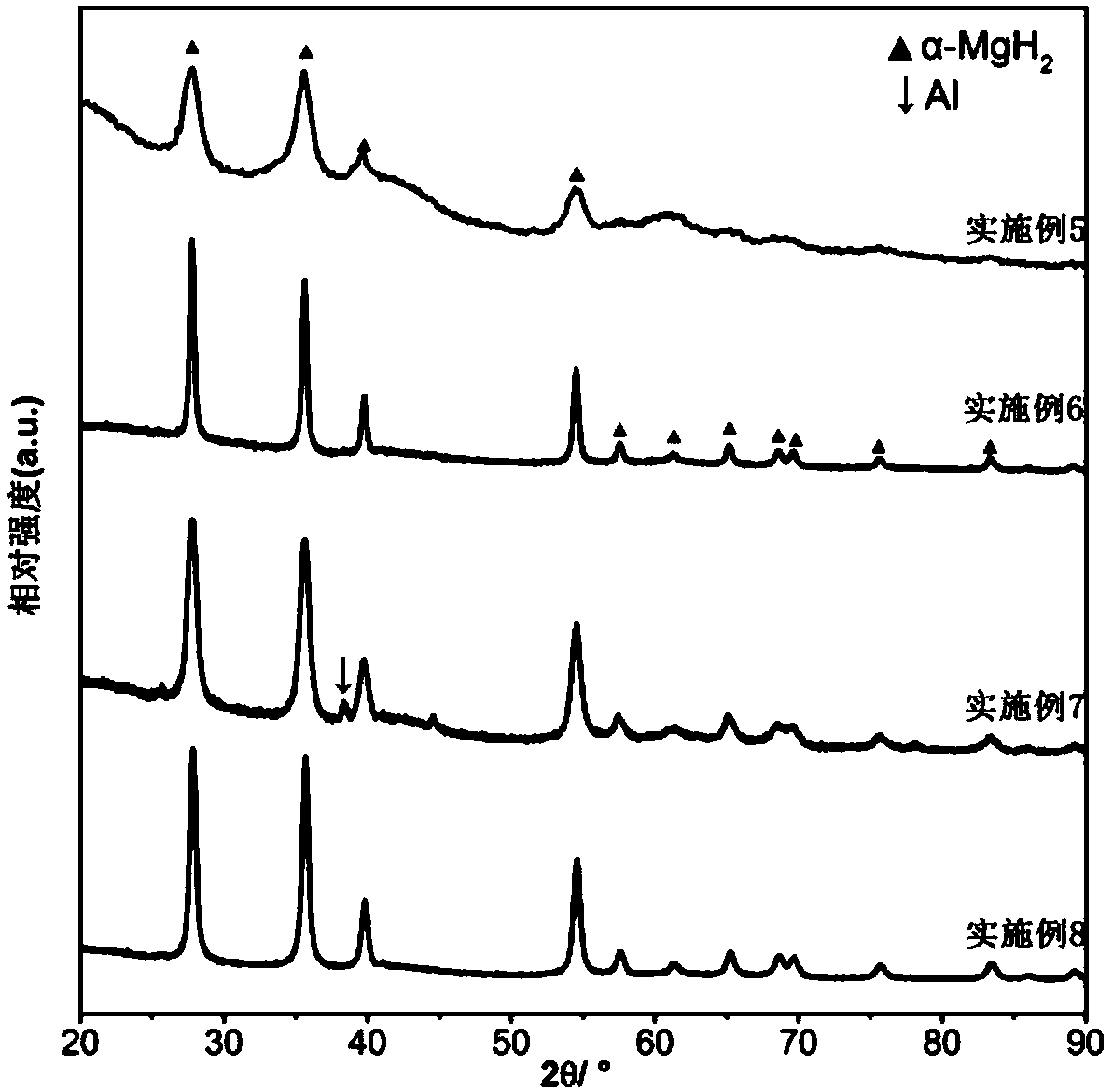

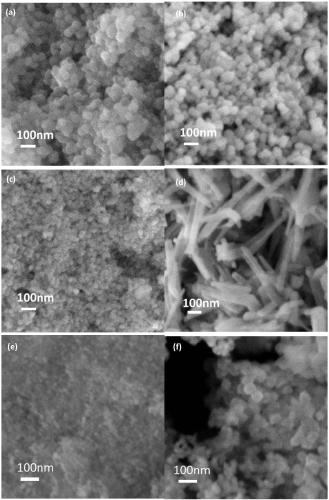

[0030] Add 15mL of 1mol / L dibutylmagnesium heptane solution into a 200mL vacuum stainless steel planetary ball mill tank, then add 75g of stainless steel ball mill balls, and clean the atmosphere in the ball mill tank with hydrogen after sealing the tank. The specific steps are: Hydrogen cleaning→vacuumizing→introducing hydrogen for cleaning→vacuumizing, and then introducing 3MPa hydrogen as the reaction atmosphere. Put an electric heating jacket on the jacket of the loaded planetary ball mill jar, and the heating temperature is 200°C. Use QM-1SP4 planetary ball mill, the ball milling speed is 300 r / min, every 60 minutes during the ball milling process, the cooling needs to be stopped, the gas in the tank is pumped out and 3MPa hydrogen is added. Ball mill for 1 hour to obtain a suspension containing magnesium hydride nanoparticles, open the can and take the suspension into a centrifuge tube, centrifuge, separate the solid from the liquid, and dry the solid in vacuum for 30 mi...

Embodiment 2

[0033] Add 15mL of 1mol / L dibutylmagnesium heptane solution into a 200mL vacuum stainless steel planetary ball mill tank, then add 75g of stainless steel ball mill balls, and clean the atmosphere in the ball mill tank with hydrogen after sealing the tank. The specific steps are: Hydrogen cleaning→vacuumizing→introducing hydrogen for cleaning→vacuumizing, and then introducing 3MPa hydrogen as the reaction atmosphere. Put an electric heating jacket on the jacket of the loaded planetary ball mill jar, and the heating temperature is 200°C. Use QM-1SP4 planetary ball mill, the ball milling speed is 300 r / min, every 60 minutes during the ball milling process, the cooling needs to be stopped, the gas in the tank is pumped out and 3MPa hydrogen is added. Ball mill for 2 hours to obtain a suspension containing magnesium hydride nanoparticles, open the can and take the suspension in a centrifuge tube, centrifuge, separate the solid from the solid and dry it in vacuum for 30 minutes to o...

Embodiment 3

[0036] Add 15mL of dibutylmagnesium heptane solution into a 200mL vacuum stainless steel planetary ball mill jar, then add 75g of stainless steel ball mill balls, and clean the atmosphere in the ball mill jar with hydrogen after sealing the jar. Vacuum→introduce hydrogen to clean→vacuumize, and then infuse 5MPa hydrogen as the reaction atmosphere. Put an electric heating jacket on the jacket of the loaded planetary ball mill jar, and the heating temperature is 150°C. Use the QM-1SP4 planetary ball mill, the ball milling speed is 200 r / min, every 60 minutes during the ball milling process, the cooling needs to be stopped, the gas in the tank is pumped out and 5MPa hydrogen is added. Ball mill for 4 hours to obtain a suspension containing magnesium hydride nanoparticles, open the can and take the suspension in a centrifuge tube, centrifuge, separate the solid from the solid and dry it in vacuum for 30 minutes to obtain the magnesium hydride nanoparticle powder.

[0037] The XRD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com