Hydrogen-storage alloy of metal oxide for air-conditioner

A technology for hydrogen storage alloys and hydrides, applied in the field of rare earth metals or lanthanide compounds, can solve the problems of increasing hydrogen absorption time, the equilibrium hydrogen pressure does not meet the requirements of hydrogen storage alloys, reducing the hydrogen absorption capacity of alloys, etc., and achieving convenient activation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of hydrogen storage alloy La 0.6 Nd 0.4 Ni 4.8 mn 0.2 Cu 0.1 Alloy button ingots are formulated according to the design composition, and the metal purity (at%) used is La 99.3, Nd99, Ni 99.9, Cu 99.9, Mn 99.5. Clean the above-mentioned raw materials with an ultrasonic oscillator, then distribute the weight according to the design composition, put the prepared material in a water-cooled copper mold, and melt it in an electric arc furnace under the protection of an argon atmosphere. During the melting process, the alloy is turned over and weighed. Melt five times while carrying out electromagnetic stirring to ensure the uniformity of the alloy. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace, heat it up to 1100°C for 8 hours, and then quench it (the preparation method is an existing mature technology).

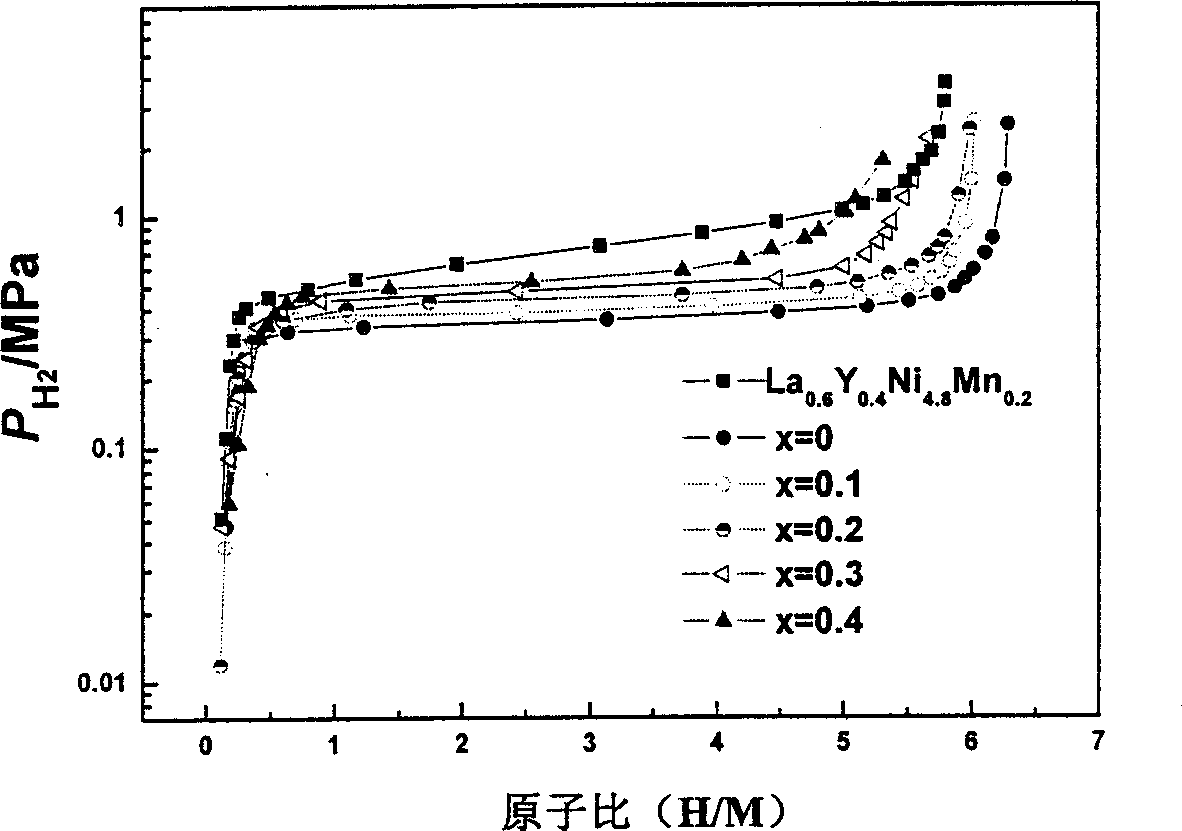

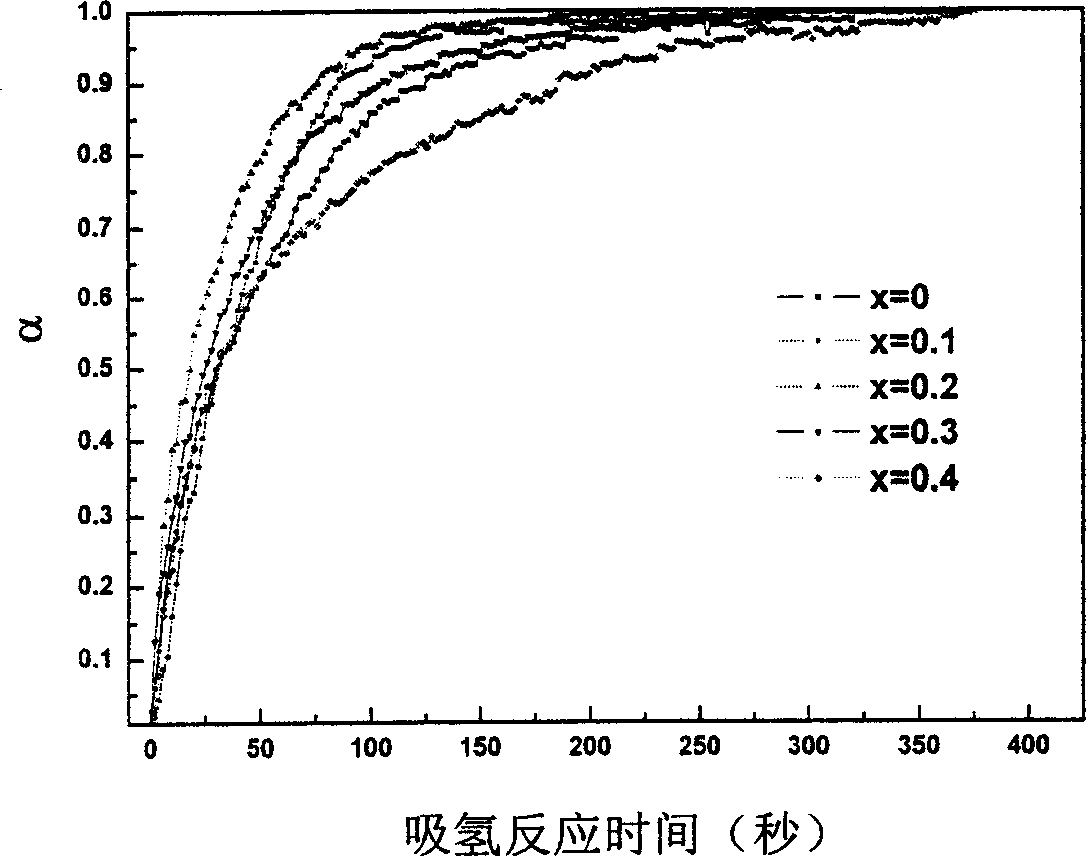

[0031] The hydrogen storage performance of the alloy is tested on a P-C-T tester, and the volumetric m...

Embodiment 2

[0039] The difference from Example 1 is: preparation and testing of hydrogen storage alloy La 0.6 Nd 0.4 Ni 4.8 mn 0.2 Cu 0.2 .

[0040] Measured results: the hydrogen storage capacity of the formed hydride is 1.4wt%, and the decomposition pressure is 0.13Mpa at 18°C. The hydrogen storage capacity of this alloy is higher than that of La 0.6 Y 0.4 Ni 4.8 mn 0.2 , the slope and hysteresis are significantly lower than La 0.6 Y 0.4 Ni 4.8 mn 0.2 , the hydrogen absorption rate is much higher than that of La 0.6 Nd 0.4 Ni 4.8 mn 0.2 , and easy to activate, the reaction enthalpy and decomposition pressure are suitable for the use of metal hydride air conditioners, and can be used with LaNi 4.61 mn 0.26 al 0.13 The hydrogen storage alloy works as an alloy to design a single-stage hydride air conditioner, working at an operating temperature of 140-160°C / 30-60°C / 10-20°C.

[0041] In this embodiment La 0.6 Nd 0.4 Ni 4.8 mn 0.2 Cu 0.2 The hydrogen absorption and des...

Embodiment 3

[0043] The difference from Example 1 is: preparation and testing of hydrogen storage alloy La 0.6 Nd 0.4 Ni 4.8 mn 0.2 Cu 0.3 .

[0044] Measured results: the hydrogen storage capacity of the formed hydride is 1.26wt%, and the decomposition pressure is 0.16Mpa at 18°C. The hydrogen storage capacity of this alloy has decreased, and the slope and hysteresis are significantly lower than La 0.6 Y 0.4 Ni 4.8 mn 0.2 , the hydrogen uptake rate is higher than that of La 0.6 Nd 0.4 Ni 4.8 mn 0.2 , and easy to activate, the reaction enthalpy and decomposition pressure are suitable for the use of metal hydride air conditioners, and can be used with LaNi 4.61 mn 0.26 al 0.13 The hydrogen storage alloy works as an alloy to design a single-stage hydride air conditioner, working at an operating temperature of 140-160°C / 30-60°C / 10-20°C.

[0045] In this embodiment La 0.6 Nd 0.4 Ni 4.8 mn 0.2 Cu 0.3 The hydrogen absorption and desorption PCT curve see Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com