Magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and preparation method thereof

A technology of coke activated carbon and hydrogen storage material, which is applied in the field of magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and its preparation, and can solve the problems of restricting practical use, plastic deformation failure of the reaction bed, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

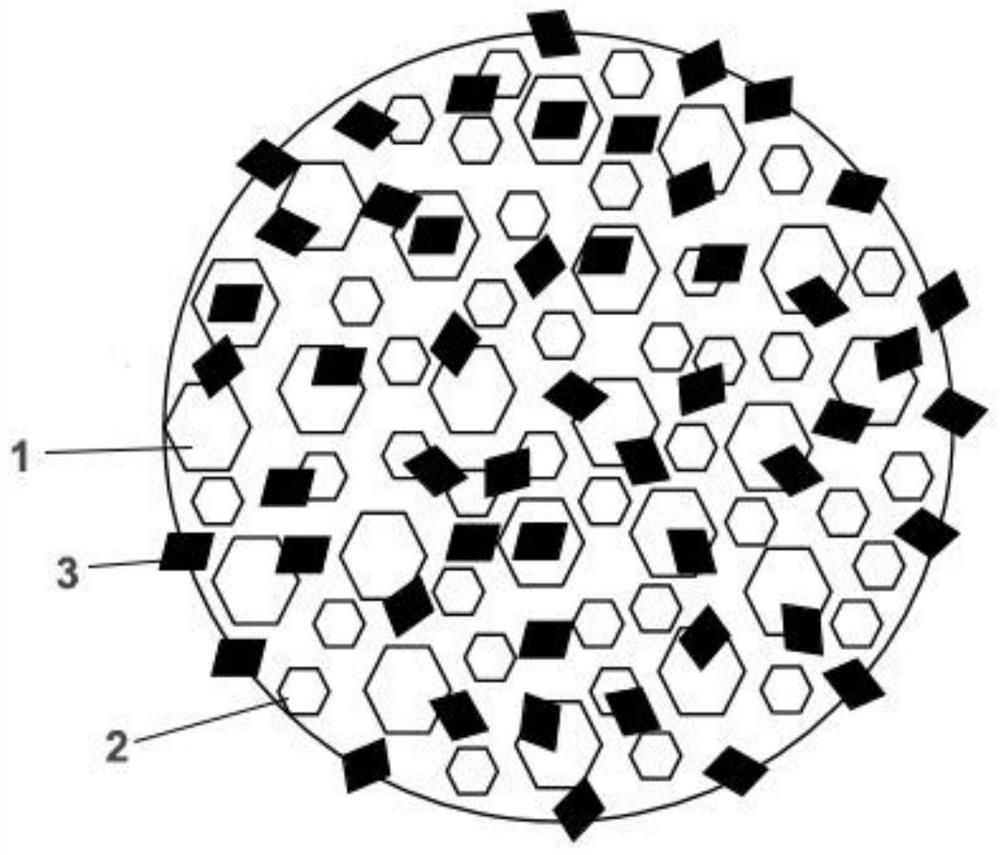

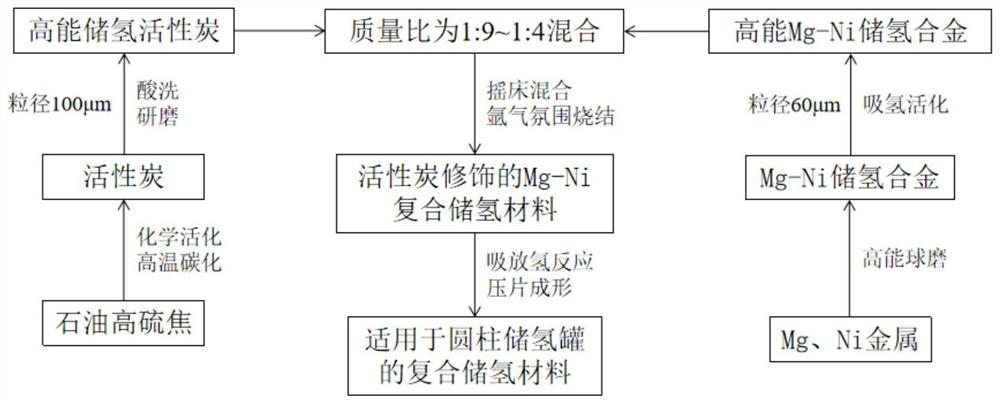

[0039] A kind of preparation method of magnesium nickel-petroleum coke activated carbon composite hydrogen storage material, see figure 1 ,include:

[0040] Step 1: Petroleum coke activated carbon preparation:

[0041] 11) Take high-sulfur petroleum coke with a mass ratio of 1:3 and mix it with KOH, put it into a tube furnace for chemical activation and high-temperature carbonization under the protection of high-purity nitrogen: raise the temperature to 400°C at a heating rate of 5°C / min Keep it for 1h for chemical activation, then raise it to 800°C and keep it for 1h for high-temperature carbonization, and cool it to room temperature for later use;

[0042] 12) Add 1mol / L HCl solution to the mixture to adjust pH=7;

[0043] 13) Grinding the activated carbon to an average particle size of 100 μm after drying;

[0044] Step 2: Preparation of Mg-Ni hydrogen storage alloy:

[0045] 21) Put Mg powder and Ni powder with a mass ratio of 84:16 in a ball mill, and conduct ball mil...

Embodiment 2

[0057] A preparation method of a magnesium-nickel-petroleum coke activated carbon composite hydrogen storage material, comprising:

[0058] Step 1, step 2 are all identical with step 1-2 in embodiment 1;

[0059] Step 3: Loading of Composite Hydrogen Storage Material:

[0060] 31) Put petroleum coke activated carbon and Mg-Ni hydrogen storage alloy with a mass ratio of 1:9 on a shaker in a glove box, vibrate and mix in an argon atmosphere for 0.h, and then place it in a muffle furnace protected by an argon atmosphere High temperature sintering, the sintering temperature is 1500°C, and the time is 1h;

[0061] 32) Place the sintered composite hydrogen storage material in a hydrogenation reactor for activation treatment. The hydrogenation temperature is 220°C, the hydrogen pressure is 2Mpa, and the hydrogen absorption and desorption time is set at 10 minutes. A total of 5 hydrogen absorption and desorption cycles are performed, and the surface powder is discarded;

[0062] 33)...

Embodiment 3

[0064] A preparation method of a magnesium-nickel-petroleum coke activated carbon composite hydrogen storage material, comprising:

[0065] Step 1, step 2 are all identical with step 1-2 in embodiment 1;

[0066] Step 3: Loading of Composite Hydrogen Storage Material:

[0067] 31) Put petroleum coke activated carbon and Mg-Ni hydrogen storage alloy with a mass ratio of 1:4 on a shaker in a glove box, vibrate and mix in an argon atmosphere for 1 hour, and then place it on a muffle furnace protected by an argon atmosphere at high temperature Sintering, the sintering temperature is 1500°C, and the time is 2h;

[0068] 32) Place the sintered composite hydrogen storage material in a hydrogenation reactor for activation treatment, the hydrogenation temperature is 250°C, the hydrogen pressure is 1Mpa, the hydrogen absorption and desorption time is set at 10min, a total of 5 hydrogen absorption and desorption cycles are performed, and the surface powder is discarded;

[0069] 33) Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com