A kind of lithium sodium double alkali metal aluminum hydride compound and its synthetic method

A synthesis method and alkali metal technology, applied in the field of lithium sodium double alkali metal aluminum hydride and its synthesis, can solve the problems of dehydrogenation rate to be improved, poor hydrogen absorption kinetics, high initial dehydrogenation temperature, etc., to achieve absorption and release Effects of increased hydrogen rate, low molecular weight, and reduced initial dehydrogenation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

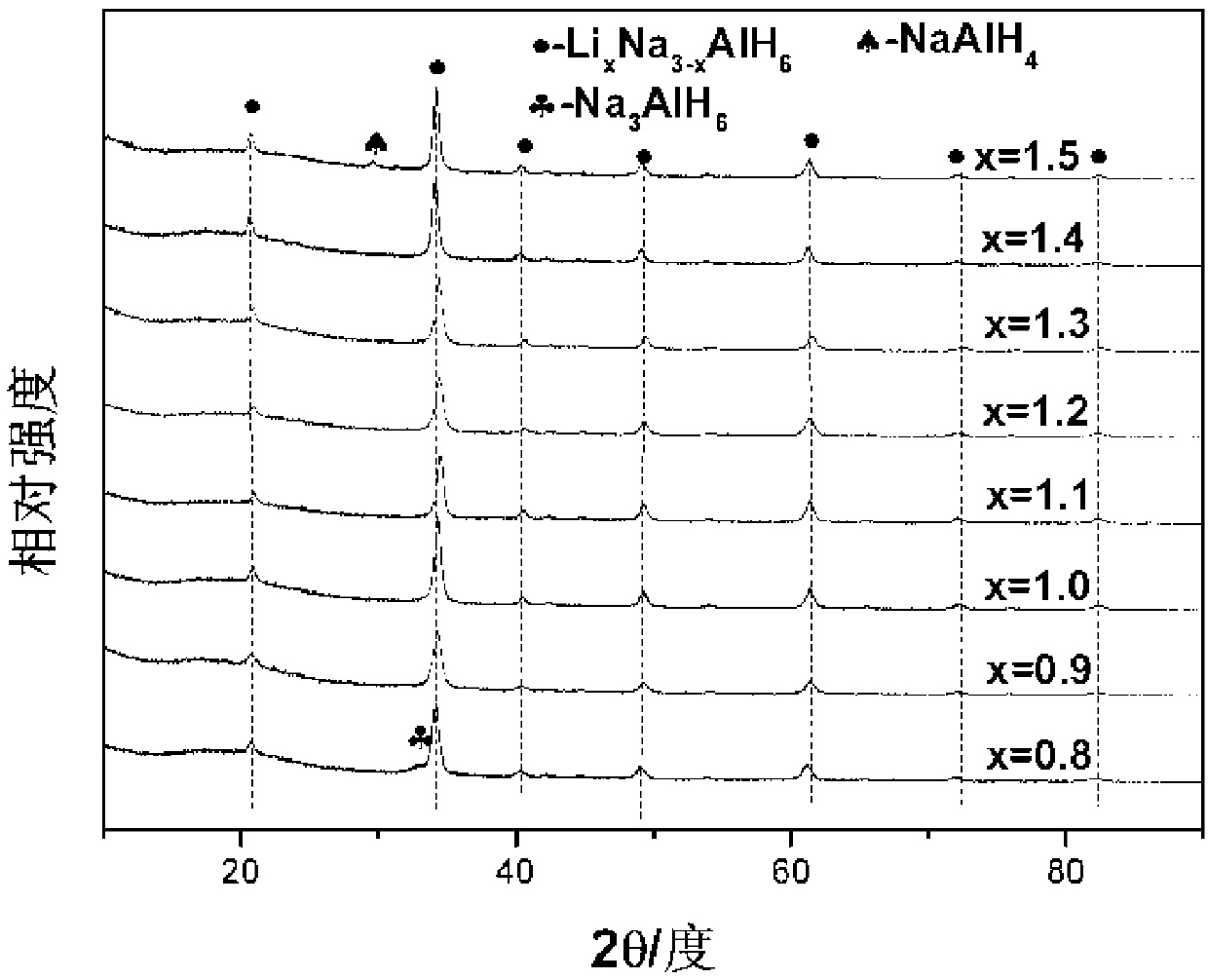

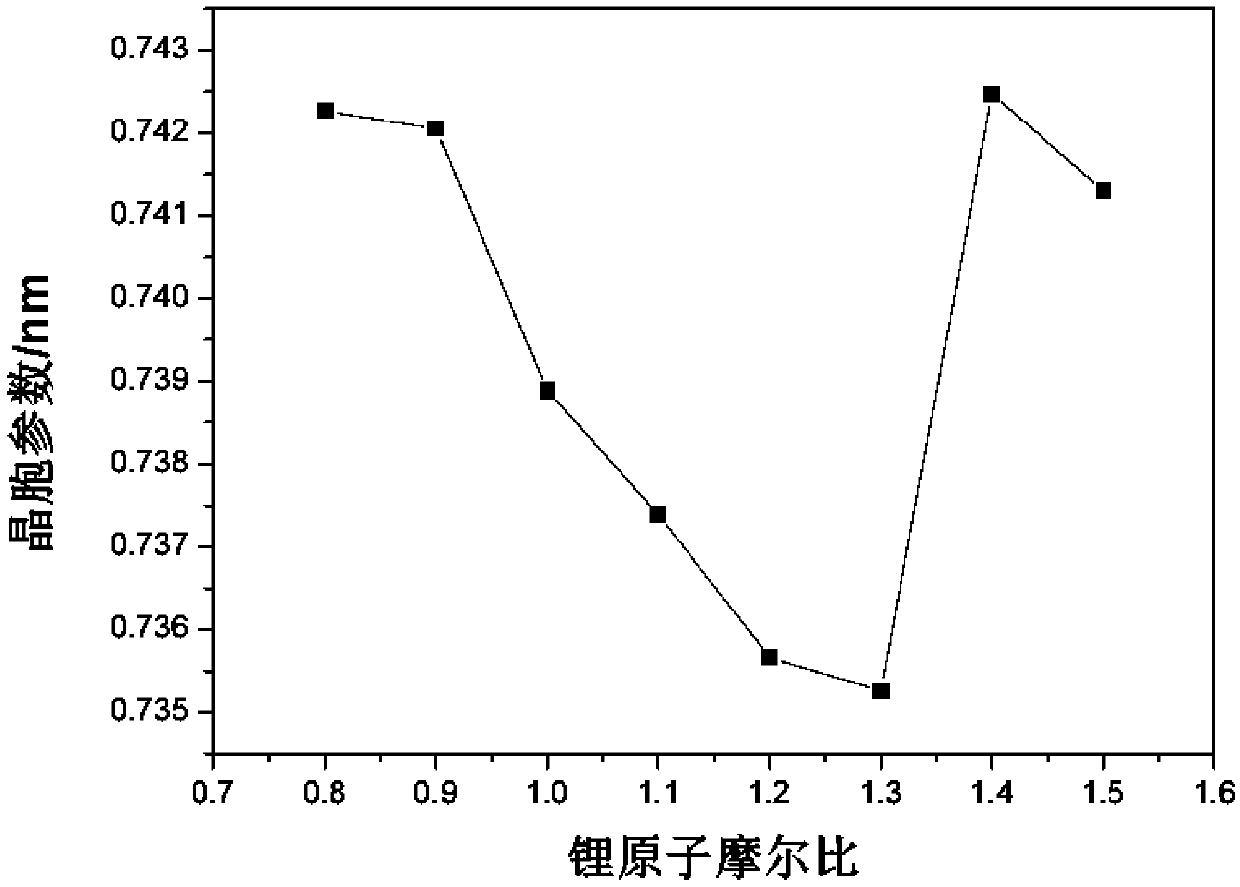

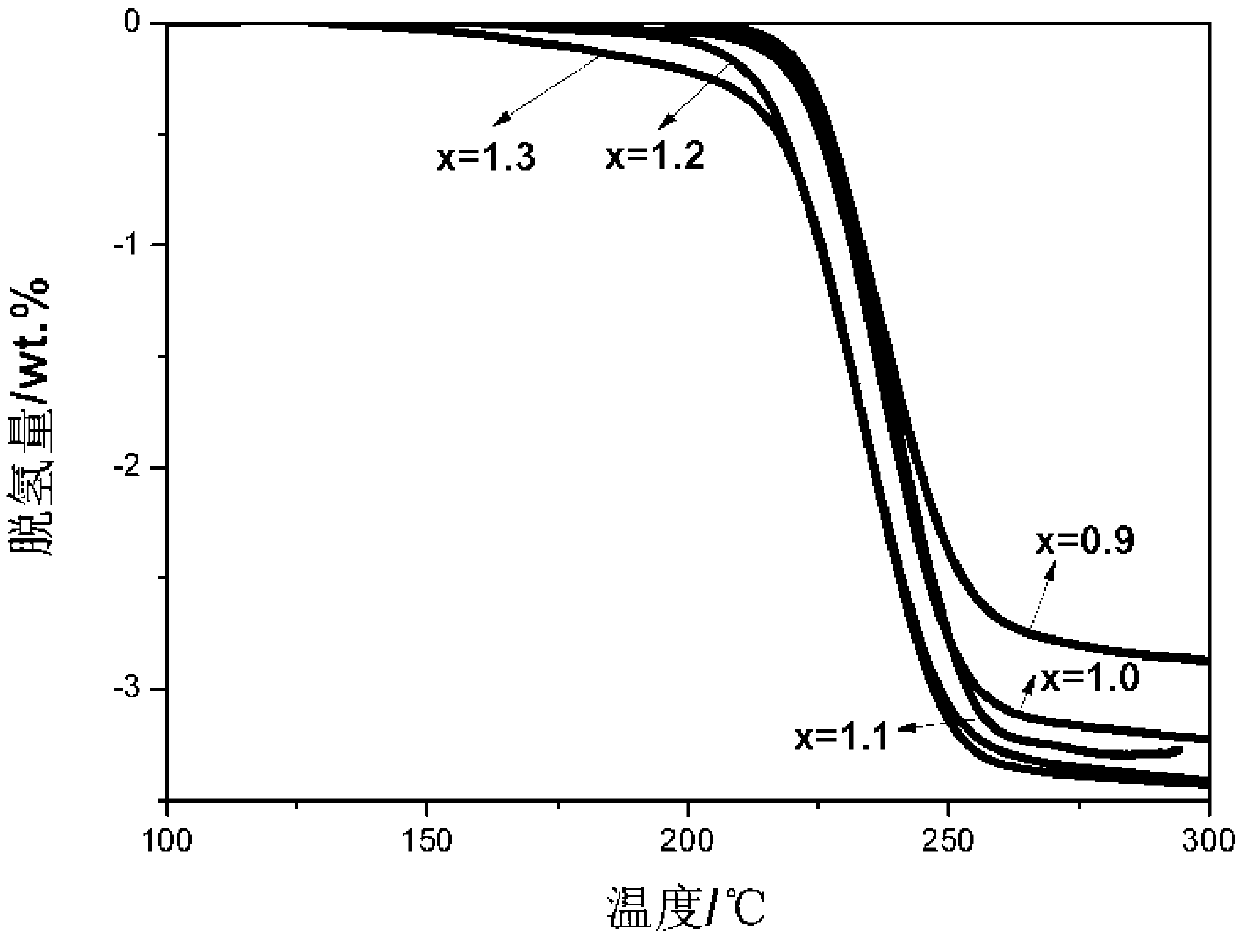

[0031] Li will be prepared 3 H 6 with Na 3 H 6 The powder was mixed according to the Li-Na molar ratio of 0.9:2.1, and put into a ball mill jar under an argon atmosphere, in which the balls were mixed with Li 3 H 6 Powder and Na 3 H 6 The ratio of the total mass of the two powders is 30:1. Afterwards, the ball mill jar was loaded on the star ball mill, and the Li 0.9 Na 2.1 H 6 Powder, determined by XRD test Li 0.9 Na 2.1 H 6 Pure phase, test its hydrogen storage performance according to the above method, and the dehydrogenation temperature is 210 ° C ~ 260 ° C.

example 2

[0033] Li will be prepared 3 H 6 with Na 3 H 6 The powder was mixed according to the Li-Na molar ratio of 1.0:2.0, and put into a ball mill jar under an argon atmosphere, in which the balls were mixed with Li 3 H 6 Powder and Na 3 H 6 The ratio of the total mass of the two powders is 40:1. Afterwards, the ball mill jar was loaded on the star ball mill, and the Li 1.0 Na 2.0 H 6 Powder, determined by XRD test Li 1.0 Na 2.0 H 6 Pure phase, test its hydrogen storage performance according to the above method, and the dehydrogenation temperature is 210 ° C ~ 260 ° C.

example 3

[0035] Li will be prepared 3 H 6 with Na 3 H 6 The powder was mixed according to the Li-Na molar ratio of 1.1:1.9, and put into a ball mill jar under an argon atmosphere, in which the balls were mixed with Li 3 H 6 Powder and Na 3 H 6 The ratio of the total mass of the two powders is 50:1. Afterwards, the ball mill jar was loaded on the star ball mill, and the Li 1.1 Na 1.9 H 6 Powder, determined by XRD test Li 1.1 Na 1.9 H 6 Pure phase, test its hydrogen storage performance according to the above method, and the dehydrogenation temperature is 210 ° C ~ 260 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com