Preparation method of in-situ growth nano magnesium hydride loaded high specific surface material

An in-situ growth, high specific surface technology, applied in chemical instruments and methods, alkali metal/alkaline earth metal/beryllium/magnesium hydride, hydrogen, etc., can solve problems such as safety hazards, high hydrogen pressure and reaction temperature, and achieve The effect of improving thermodynamics, low operating temperature, and fast hydrogen absorption and desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method for in-situ growth of nano-magnesium hydride-loaded high specific surface material, using alkali metal hydride, magnesium halide and supporting material to synthesize in-situ under the condition of ball milling, the specific steps are as follows:

[0020] 0.4g of LiH, 2.0g of MgCl 2 and 0.07g reduced graphene are put into ball mill jar, mix uniformly; Ball mill 30 hours under the rotating speed of 450rpm under the hydrogen pressure of 0.5MPa; The mixture obtained is washed 3 times with 40mL tetrahydrofuran as solvent, centrifuged, remove solvent, Vacuum drying under 50 Pa for 14 hours to obtain the target product.

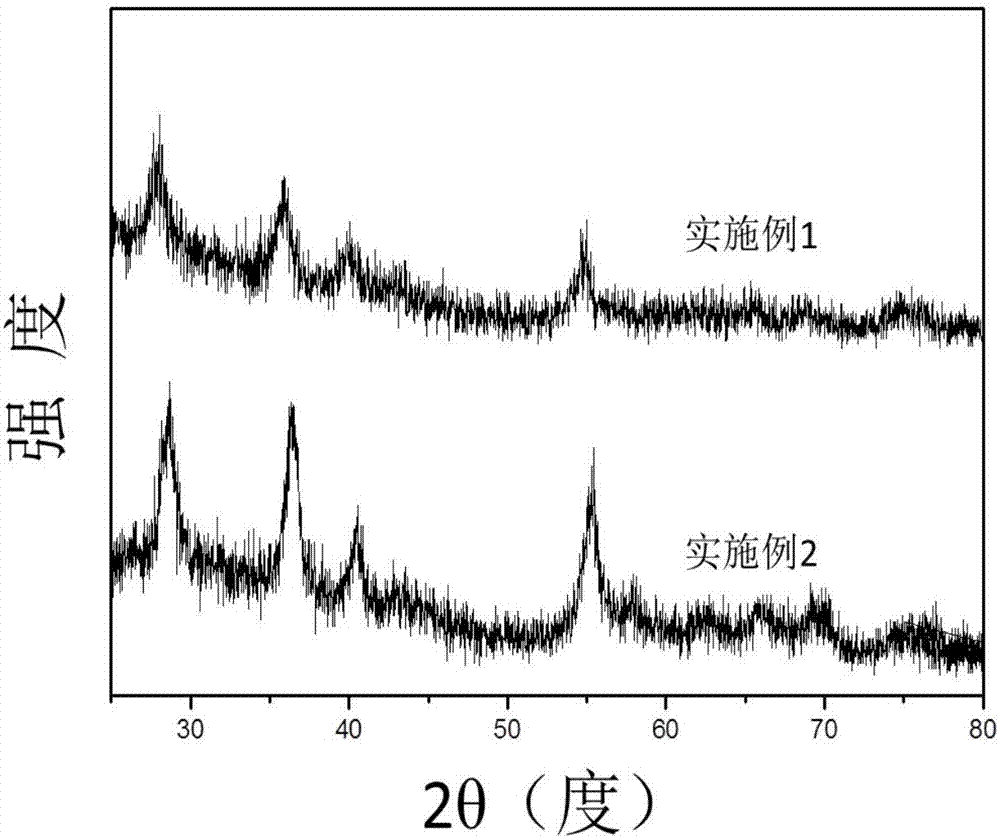

[0021] The prepared graphene carries magnesium hydride and coconut shell carbon carries the XRD patterns of magnesium hydride nanomaterials as follows figure 1 As shown in the figure, it shows that the obtained product is tetragonal MgH 2 , and no other impurities.

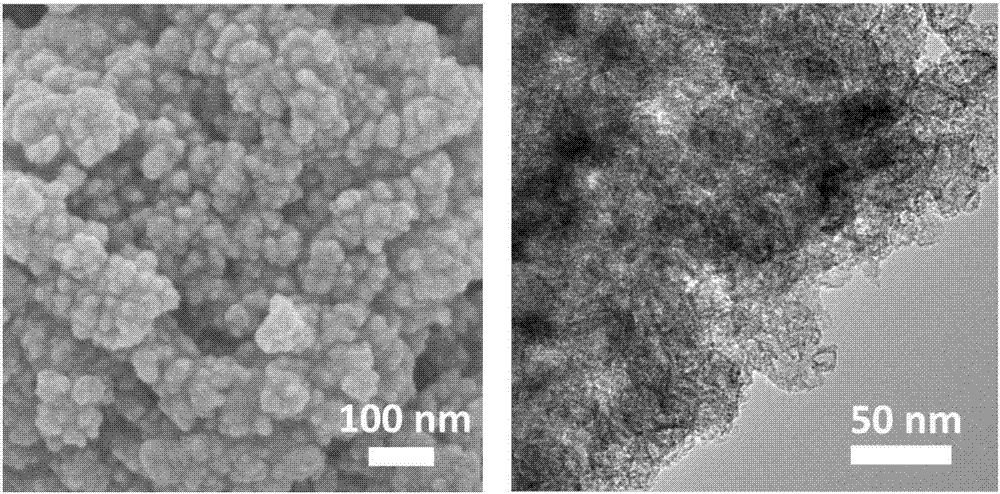

[0022] figure 2 The SEM and TEM images of the prepared graphene ca...

Embodiment 2

[0025] A preparation method for in-situ growth of nano-magnesium hydride-loaded high specific surface material, using alkali metal hydride, magnesium halide and supporting material to synthesize in-situ under the condition of ball milling, the specific steps are as follows:

[0026] 0.4g of LiH, 2.0g of MgCl 2 and 0.10g of coconut shell charcoal are put into a ball mill jar and mixed evenly. Ball milling at 450rpm under a hydrogen pressure of 0.5MPa for 30 hours; the resulting mixture was washed three times with 40mL tetrahydrofuran as a solvent, centrifuged to remove the solvent; vacuum-dried below 50Pa for 14 hours to obtain the target product.

[0027] The prepared graphene carries magnesium hydride and coconut shell carbon carries the XRD patterns of magnesium hydride nanomaterials as follows figure 1 As shown in the figure, it shows that the obtained product is tetragonal MgH 2 , and no other impurities.

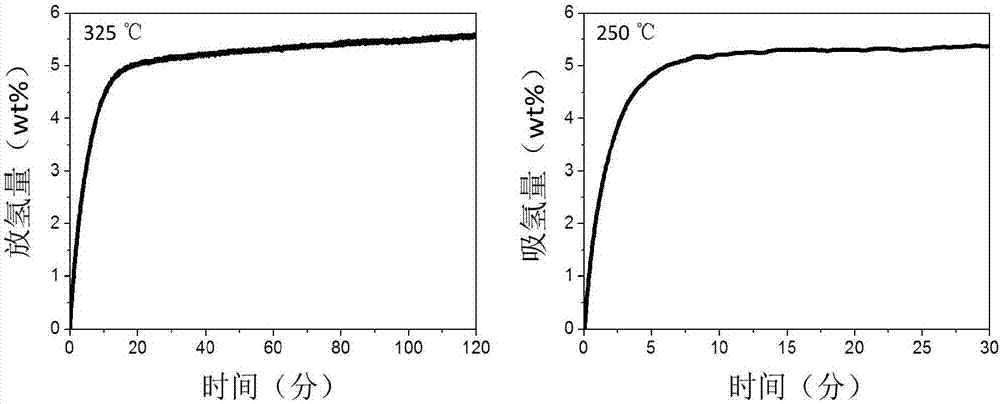

[0028] Figure 4 Shown in the temperature-programmed dehydroge...

Embodiment 3

[0030] A preparation method for in-situ growth of nano-magnesium hydride-loaded high specific surface material, using alkali metal hydride, magnesium halide and supporting material to synthesize in-situ under the condition of ball milling, the specific steps are as follows:

[0031] 0.4g of LiH, 2.0g of MgCl 2 and 0.10g of fly ash were put into a ball mill jar, and mixed uniformly; ball milled for 40 hours under a hydrogen pressure of 0.5MPa at a speed of 500rpm; the obtained mixture was washed 3 times with 60mL tetrahydrofuran as a solvent, and centrifuged to remove the solvent; Vacuum drying under 50 Pa for 14 hours to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com