Fast and energy-saving method and device for preparing Mg2NiH4 hydride

A hydride, fast technology, applied in various metal hydrides, chemical industry, sustainable manufacturing/processing, etc. Effects of rate enhancement, microwave leakage suppression, sample composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

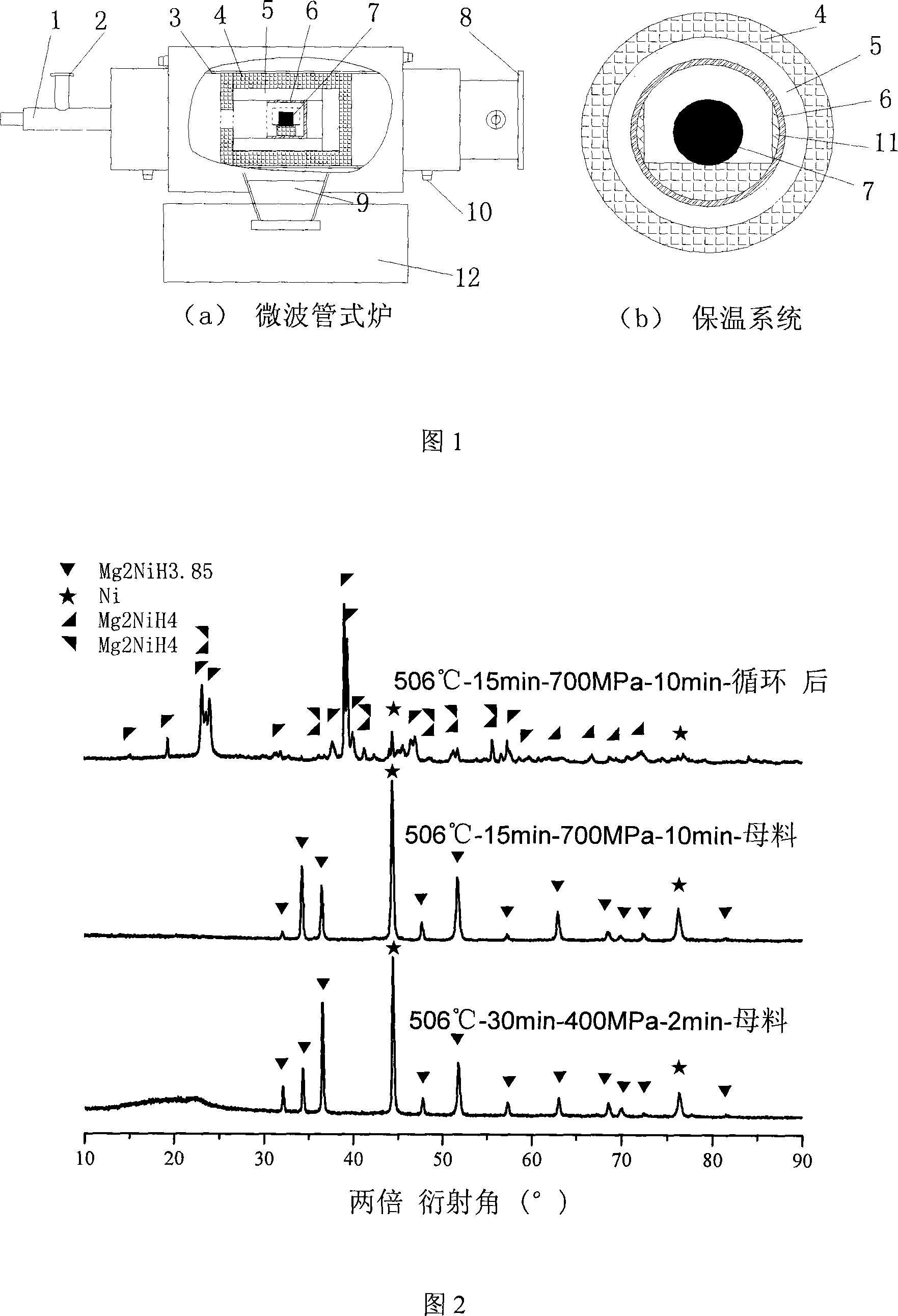

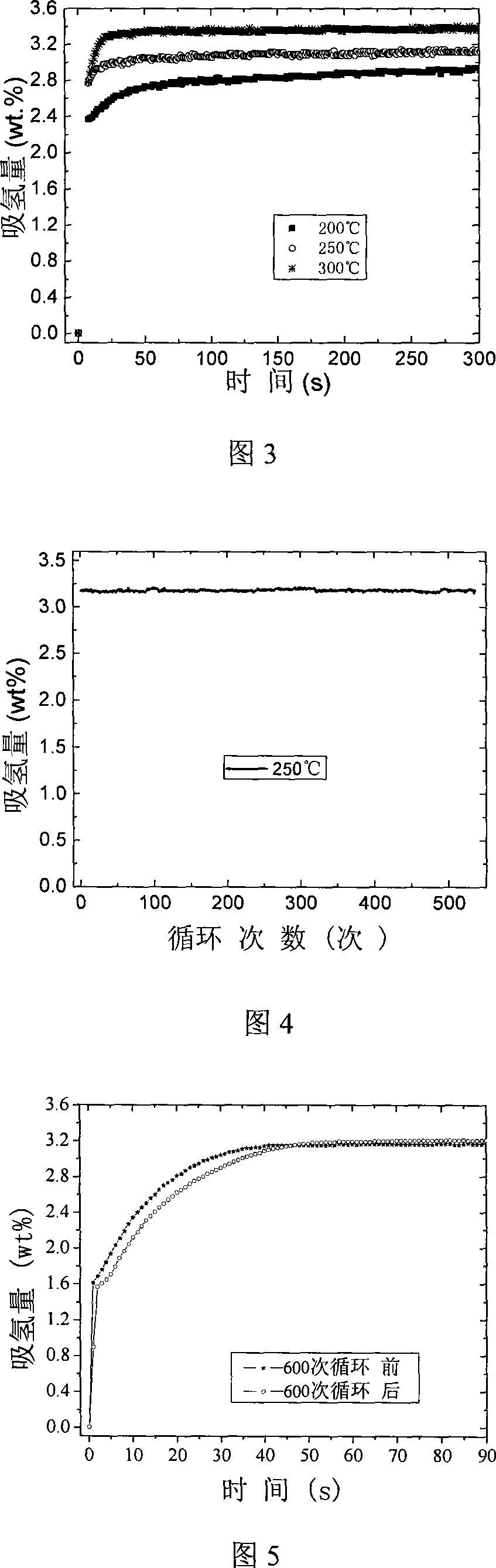

[0031] According to the hydrogen storage alloy Mg 2 The amount determined by Ni chemical composition weighs Mg and Ni metal powders, puts them in ethanol after mixing, carries out ultrasonic vibration dispersion to make them fully mixed, and then puts them into a vacuum drying oven for vacuum drying until all organic solvents are completely volatilized; The above mixture was pressed and formed under a pressure of 700MPa, and the pressure was maintained for 10 minutes; the above samples were fixed in a corundum crucible, and the corundum crucible was covered with heat-insulating materials. Place them together in a microwave tube furnace with a frequency of 2.4GHz, evacuate to below 150Pa, and then pass in argon gas with a purity ≥ 99.9% as a protective atmosphere to keep the internal pressure of the crucible at 0.1-0.12MPa; turn on the microwave power supply, and use 100- Heating at a heating rate of 300°C / min. The heating rate fluctuates within the range of 100-300°C / min. Afte...

Embodiment 2

[0033] According to the hydrogen storage alloy Mg 2 The amount determined by the Ni chemical composition weighs Mg and Ni metal powders, mixes them and places them in ethanol, carries out ultrasonic vibration dispersion to make them fully mixed, and then puts them into a vacuum drying oven for vacuum drying; Press and form, keep the pressure for 2 minutes; fix the above sample in a corundum crucible, and wrap the heat insulation material on the outside. Place them together in a microwave tube furnace with a frequency of 2.4GHz, evacuate to below 150Pa, and then pass in argon gas with a purity ≥ 99.9% as a protective atmosphere to keep the internal pressure of the crucible at 0.1-0.12MPa; turn on the microwave power supply, and use 100- Heating at a heating rate of 300°C / min, the heating rate fluctuates within the range of 100-300°C / min, heat up to 506°C and keep warm for 2 minutes, during which the carrier gas is passed until the sample temperature is lower than 300°C, then th...

Embodiment 3

[0035] According to the hydrogen storage alloy Mg 2 The amount determined by the Ni chemical composition weighs Mg and Ni metal powders, mixes them and puts them in ethanol, carries out ultrasonic vibration dispersion to make them fully mixed, and then puts them into a vacuum drying oven for vacuum drying; the above mixture is heated under 400MPa pressure Press and form, keep the pressure for 2 minutes; fix the above sample in a corundum crucible, and wrap the heat insulation material on the outside. Place them together in a microwave tube furnace with a frequency of 2.4GHz, evacuate to below 150Pa, and then pass in argon gas with a purity ≥ 99.9% as a protective atmosphere to keep the internal pressure of the crucible at 0.1-0.12MPa; turn on the microwave power supply, and use 100- Heating at a heating rate of 300°C / min. The heating rate fluctuates within the range of 100-300°C / min. After the temperature is raised to 506°C, it is kept for 30 minutes. During this period, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com