Rare earth hydrogen storage alloy and preparation method and application thereof

A hydrogen storage alloy, rare earth metal technology, applied in metal processing equipment, chemical instruments and methods, hydrogen and other directions, can solve the problems of neglecting hydrogen absorption and desorption rate of hydrogen storage alloy, affecting hydrogen storage capacity, reducing hydrogen storage performance, etc. Good industrial application prospects, excellent activation performance, and fast hydrogen absorption and desorption rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a rare earth hydrogen storage alloy and a preparation method thereof, the preparation method comprising the following steps:

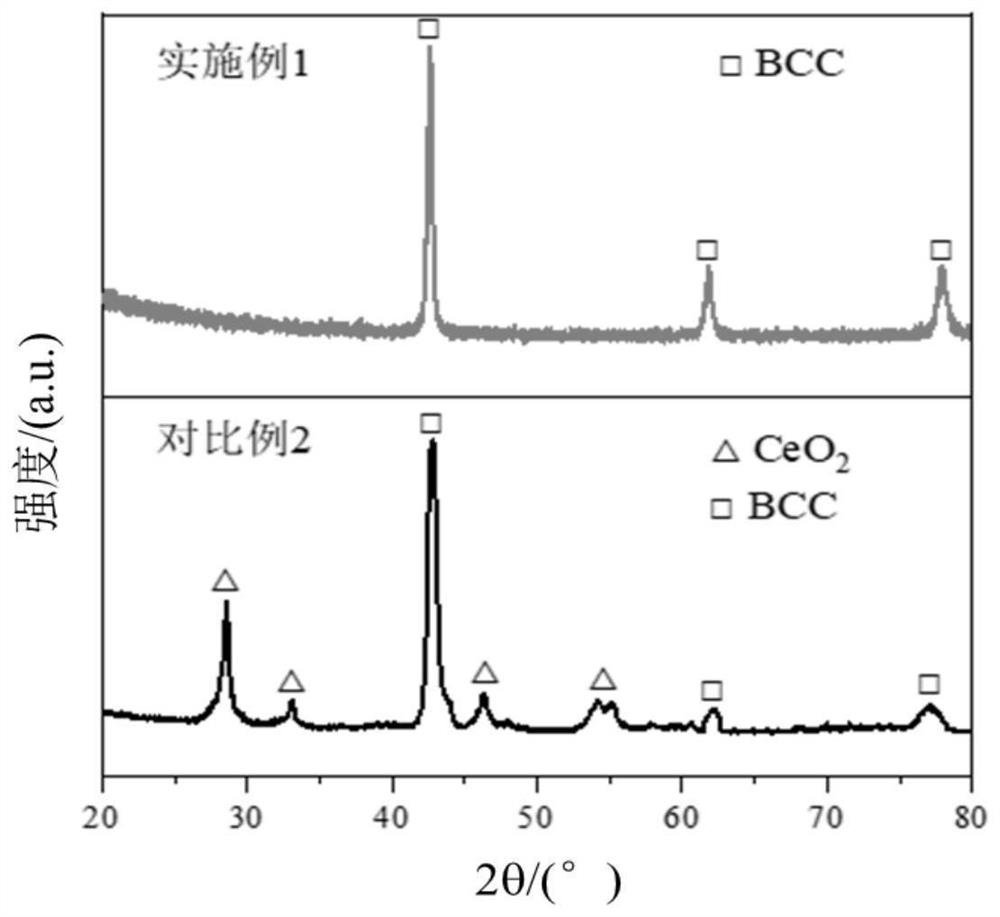

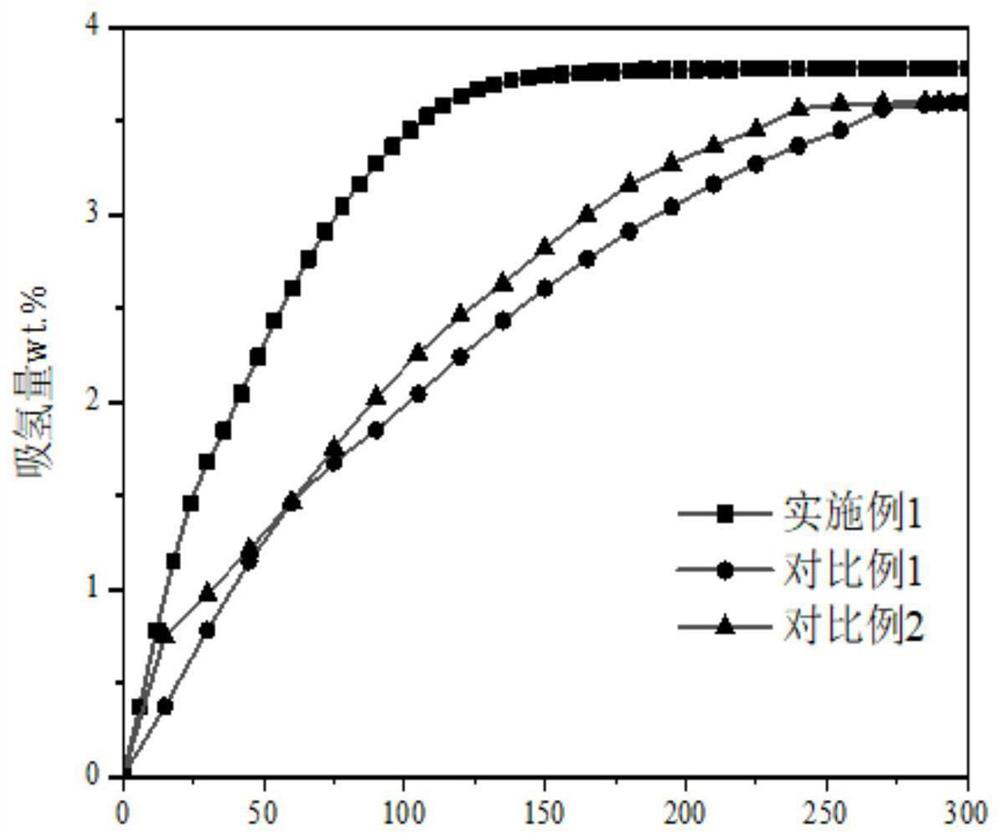

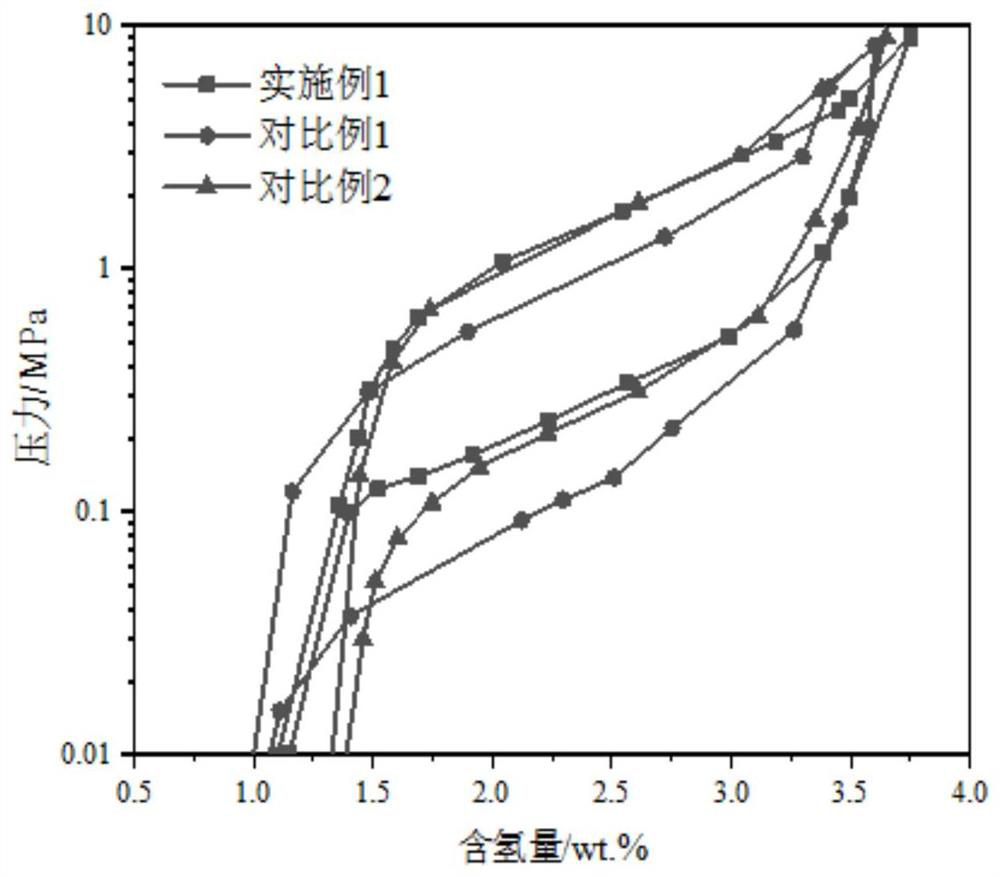

[0063] (1) Mix Ti, V, Cr, Fe and Ce according to the molar ratio of 0.28:0.42:0.24:0.06:0.05. After mixing, smelt for 20s under the condition of smelting current of 150A, and smelt 5 times; Vacuum suction casting under the conditions to obtain alloy rods; the phase of the alloy rods includes cerium oxide phase;

[0064] (2) Mechanically crush the alloy rod obtained in step (1) to obtain alloy particles with a particle size of 74 μm; use a mixed acid of sulfuric acid and hydrochloric acid to modify the surface of the alloy particles at 50°C, and the modification time is 1.0h, the stirring speed is 300rpm, wherein, the hydrogen ion concentration of the mixed acid is 5.0mol / L, and the liquid-solid ratio of the mixed acid to the alloy particles is 5.0ml / g; Washing to obtain a rare earth hydrogen storage alloy.

[0065] The...

Embodiment 2

[0067] This embodiment provides a rare earth hydrogen storage alloy and a preparation method thereof, the preparation method comprising the following steps:

[0068] (1) Mix Ti, V, Cr, Fe and La according to the molar ratio of 0.28:0.42:0.24:0.06:0.05. After mixing, smelt for 20s under the condition of smelting current of 150A, and smelt 5 times; Vacuum suction casting under the conditions to obtain alloy rods; the phase of the alloy rods includes lanthanum oxide phase;

[0069] (2) Mechanically crush the alloy rod obtained in step (1) to obtain alloy particles with a particle size of 150 μm; use a mixed acid of sulfuric acid and hydrochloric acid to modify the surface of the alloy particles at 50°C, and the modification time is 1.0h, the stirring speed is 300rpm, wherein, the hydrogen ion concentration of the mixed acid is 0.5mol / L, and the liquid-solid ratio of the mixed acid to the alloy particles is 5.0ml / g; Washing to obtain a rare earth hydrogen storage alloy.

[0070]...

Embodiment 3

[0072] This embodiment provides a rare earth hydrogen storage alloy and a preparation method thereof, the preparation method comprising the following steps:

[0073] (1) Ti, Zr, Cr, Fe and Ce are mixed according to the molar ratio of 0.25:0.25:0.45:0.05:0.05, after mixing, smelting under the condition of 150A smelting current for 20s, smelting 5 times; Vacuum suction casting under the conditions to obtain alloy rods; the phase of the alloy rods includes cerium oxide phase;

[0074] (2) Mechanically crush the alloy rod obtained in step (1) to obtain alloy particles with a particle size of 100 μm; use a mixed acid of sulfuric acid and hydrochloric acid to modify the surface of the alloy particles at 100 ° C, and the modification time is 0.1h, the stirring speed is 100rpm, wherein, the hydrogen ion concentration of the mixed acid is 1.0mol / L, and the liquid-solid ratio of the mixed acid to the alloy particles is 1.0ml / g; Washing to obtain a rare earth hydrogen storage alloy.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com