Crop straw picking tipping trailer

A technology of crop straws and dump trailers, which is applied in agriculture, agricultural machinery and implements, and applications. It can solve the problems of high labor intensity of straw, waste of straw burning, and environmental pollution of resources, so as to reduce labor intensity, prolong service life, The effect of simplifying the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

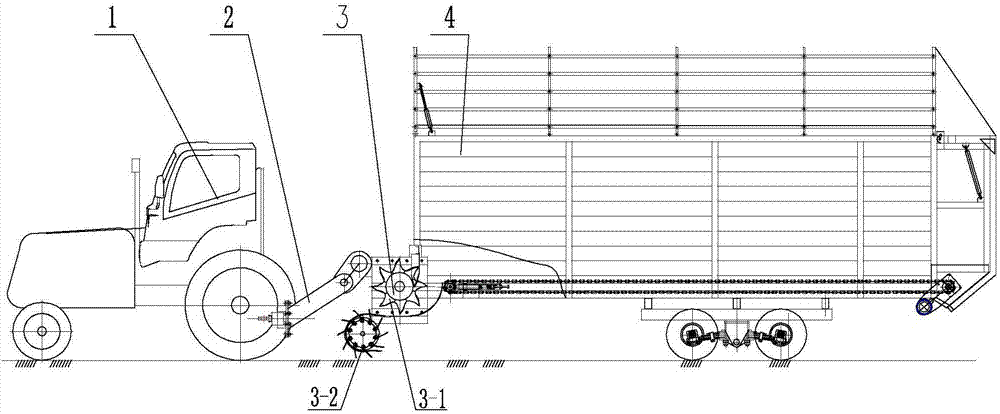

[0036]Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes tractor 1, traction device 2, picking up and pushing device 3 and straw self-unloading transport trailer 4, and picking up and pushing device 3 includes pushing loader 3-1, picker 3-2 and transmission mechanism 3-3, the push loader 3-1 and the picker 3-2 are set up and down, the input end of the transmission mechanism 3-3 is connected with the pusher spindle 3-1-6 on the push loader 3-1, and the transmission mechanism 3- The output end of 3 is connected with the picker main shaft 3-2-1 on the picker 3-2, the input end of the push loader 3-1 is connected with the output end of the traction device 2, and the traction device 2 is fixed on the tractor 1 , the pushing fixed plate 3-1-3 on the pushing loader 3-1 is fixedly connected with the box body 4-6 on the straw dump transport trailer 4. The tractor 1 is a purchased standard vehicle, and the traction device 2...

specific Embodiment approach 2

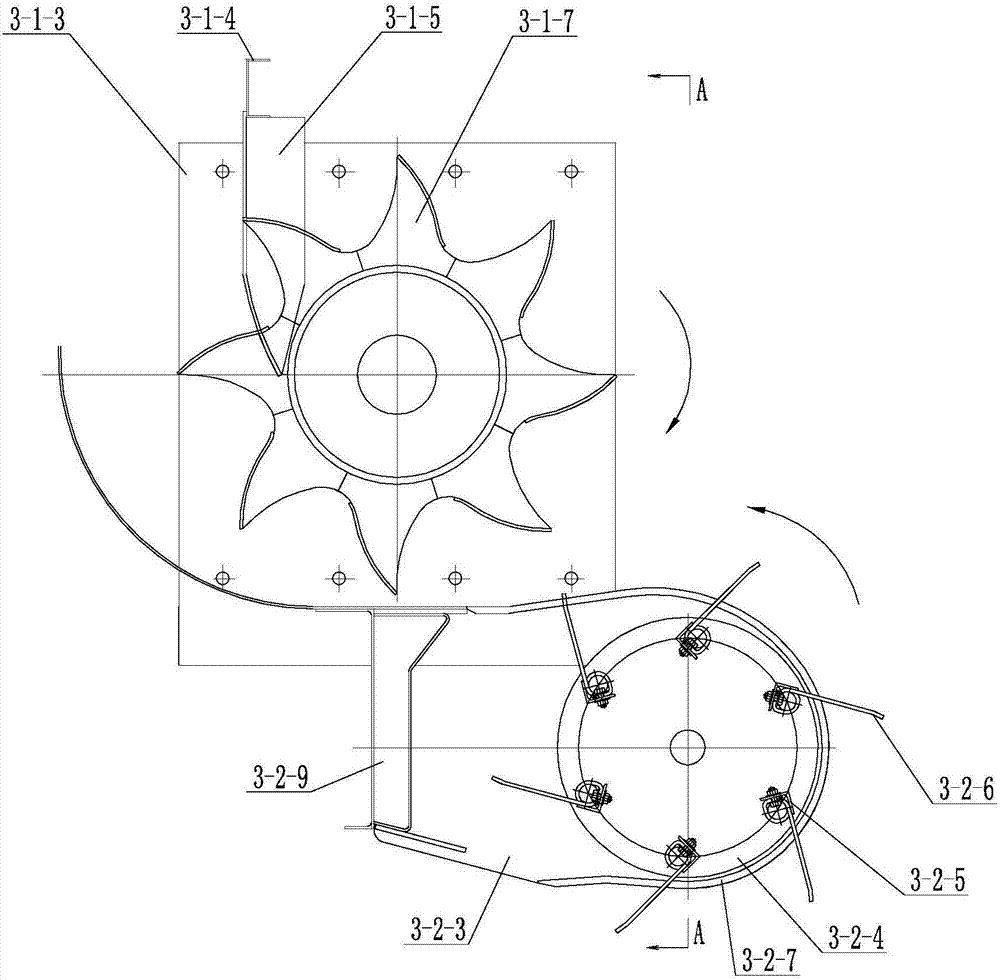

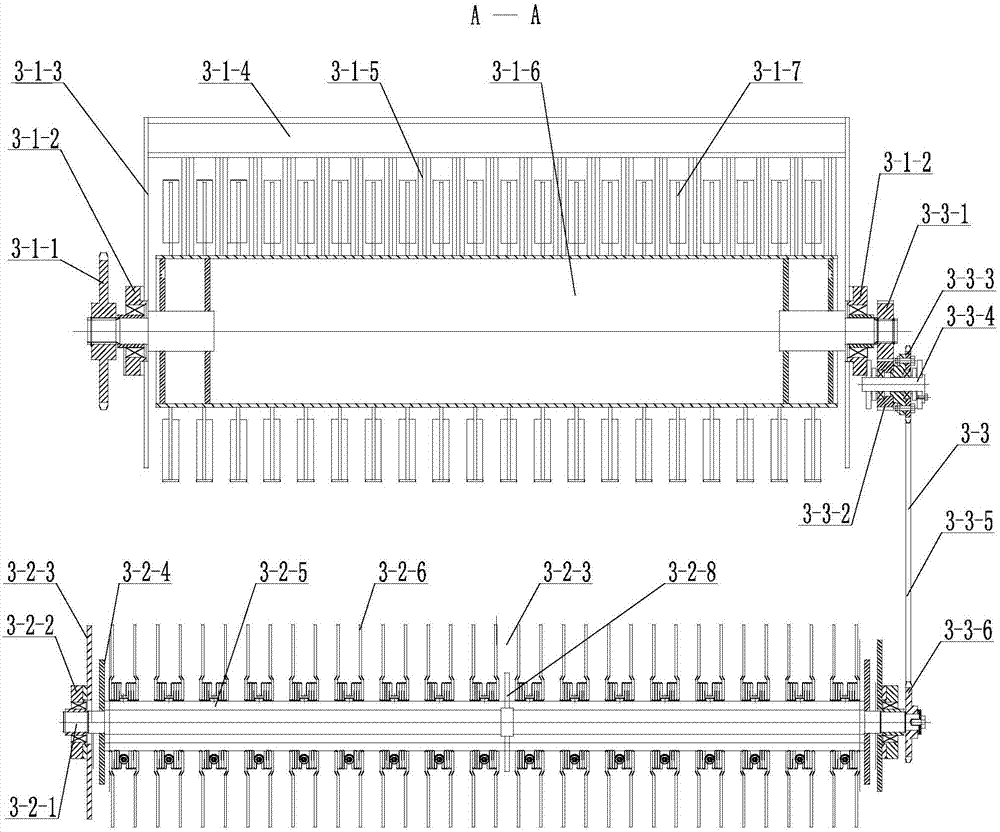

[0037] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, this embodiment is that push loader 3-1 comprises push material input shaft sprocket 3-1-1, stop material fixing frame 3-1-4, push material main shaft 3-1-6, two push material Material spindle bearing 3-1-2, two pusher fixed plates 3-1-3, several stop teeth 3-1-5 and several pusher teeth 3-1-7, two pusher fixed plates 3 -1-3 is in one-to-one correspondence with the two pusher spindle bearings 3-1-2, the inner rings of the two pusher spindle bearings 3-1-2 are installed at the two ends of the pusher spindle 3-1-6, two The outer ring of the material pushing main shaft bearing 3-1-2 is fixedly connected with the pushing material fixing plate 3-1-3, and the pushing material fixing plate 3-1-3 is set on the pushing material main shaft 3-1-6, and the pushing material fixing plate 3-1-3 is fixedly connected with the box body 4-6 on the straw self-unloading transport trailer 4, and ...

specific Embodiment approach 3

[0038] Specific implementation mode three: combination Figure 4 , Figure 5 and Figure 6 To illustrate this embodiment, in this embodiment, the push loader 3-1 also includes several arc-shaped push plates 3-1-8, and the surface of the push teeth 3-1-7 is provided with several sharp teeth 3-1 -7-1, several tines 3-1-7-1 are evenly distributed along the same circumference, and the front end of each tine 3-1-7-1 is a convex arc 3-1-7-1-1, The rear end of each tine 3-1-7-1 is a concave arc 3-1-7-1-2, several arc pusher plates 3-1-8 and several tines 3-1-7 -1 corresponds to each other, and the arc-shaped pushing plate 3-1-8 is arranged on the surface of the convex arc 3-1-7-1-1. The arc-shaped pusher plate 3-1-8 keeps the straw in the trailer compartment through the stopper tooth 3-1-5 when the push is finished, and the pusher tooth 3-1-7 passes through the stopper tooth 3-1-5 At the same time, the angle between the tangent line at the arc intersection of the retaining tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com