A kind of mg-al-y-based hydrogen storage material and preparation method thereof

A hydrogen storage material, mg-al-y technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., to achieve the effects of simple preparation process, lower dehydrogenation temperature, and improved thermodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

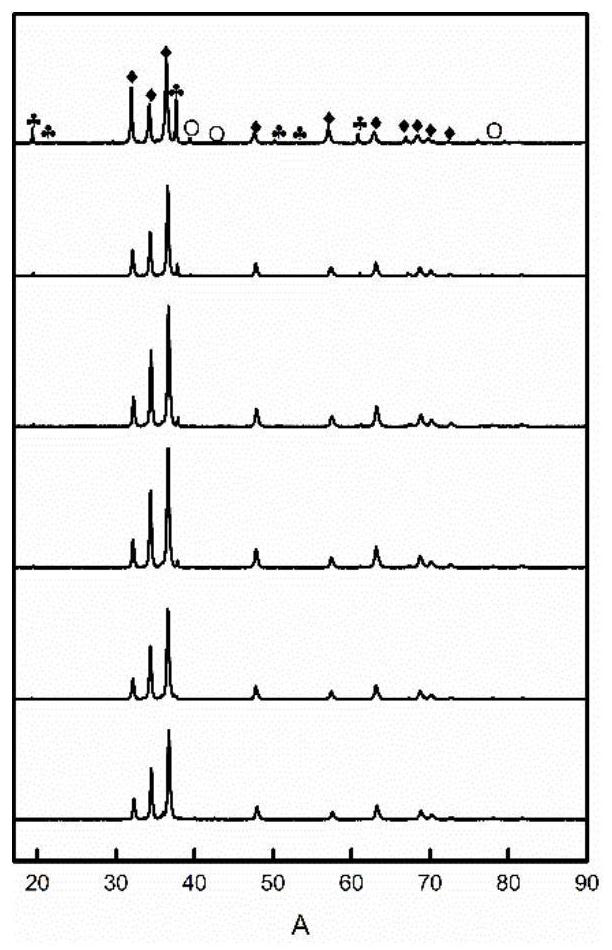

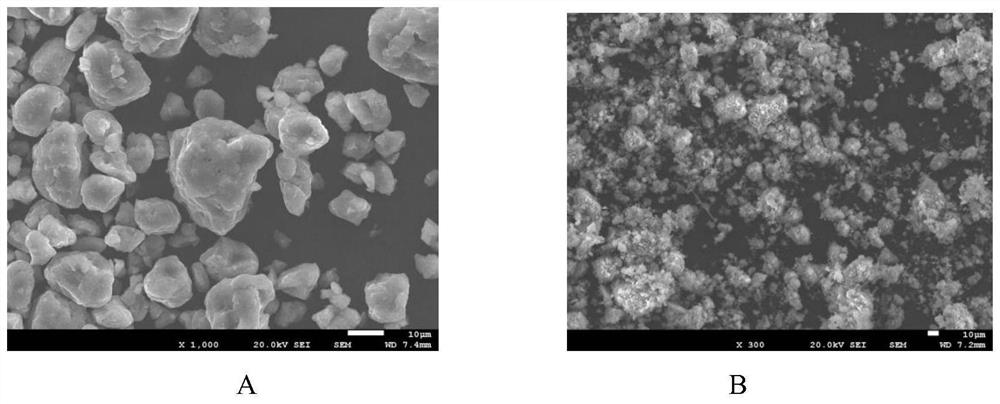

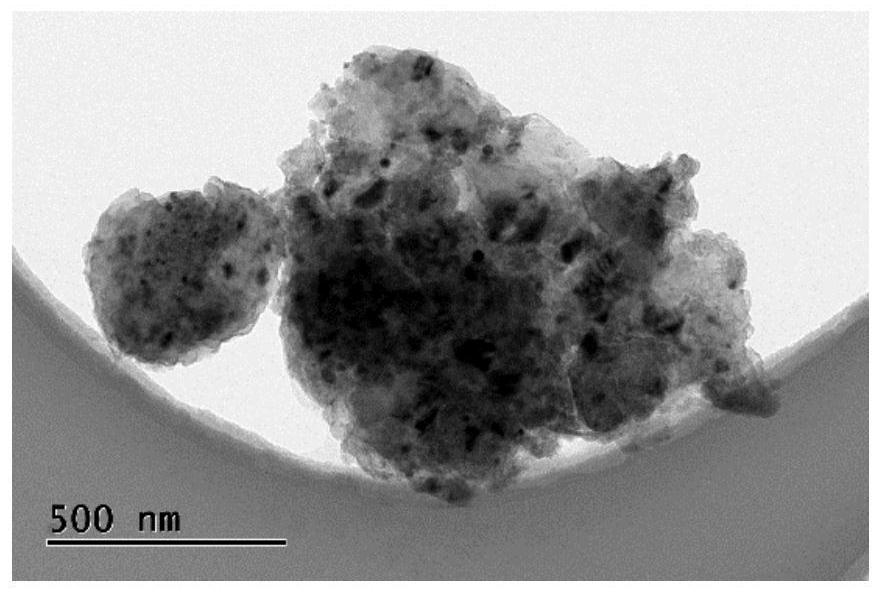

Image

Examples

preparation example Construction

[0037] A preparation method of a Mg-Al-Y-based hydrogen storage material, comprising the following steps:

[0038] (1) The as-cast Mg-Al-Y alloy is prepared by vacuum induction melting;

[0039] (2) crushing the obtained ingot alloy to obtain alloy powder;

[0040] (3) mechanically grinding the obtained alloy powder;

[0041] (4) After a period of mechanical grinding, the pre-prepared porous carbon-based catalysts Tm@C (Tm=Fe, Cu, Co, etc.) and fluorides (AF) were added d =NiF 2 ,CrF 3 ,ZrF 4 etc.), continue grinding for several hours;

[0042] (5) The hydrogen storage material obtained above is subjected to activation treatment, and then the hydrogen absorption and desorption performance test is carried out.

[0043] The prepared alloy of step (1) is Mg x Al y Y z , where x+y+z=100, 70≤x≤90, 5≤y≤15, 5≤z≤10; the product obtained in step (3) is nanocrystalline Mg x Al y Y z Alloy, the product of step (4) gained is Mg x Al y Y z +awt.%Tm@C(Tm=Fe,Cu,Co etc.)+bwt.%A...

Embodiment 1

[0053] Taking the preparation of 1000g sample as an example, put 830.11g Mg (99.99%), 160.66g Y (99.9%) and 48.76g Al (99.99%) into the vacuum induction melting furnace. Because the melting point of magnesium is lower than that of rare earth, it is placed at the bottom of the crucible. and the surrounding area are placed in metal magnesium, and rare earth is placed in the middle high temperature area. After the furnace cover is covered, the vacuum is evacuated to a vacuum degree below 0.05Pa. At the same time, it is heated with a power of 0.2KW, kept for 10 minutes, and then evacuated to a vacuum degree below 0.05Pa. , and then introduce an inert gas of 0.06 MPa as the protective gas, the protective gas is pure helium or a helium+argon mixed gas, and the volume ratio of the mixed gas is about 1:1. The heating power at the beginning of smelting is gradually adjusted from 0.2KW to 1kW, and the temperature is controlled at about 800-850°C to melt the metal magnesium, and then the ...

Embodiment 2

[0056] Taking the preparation of 1000g sample as an example, put 830.11g Mg (99.99%), 160.66g Y (99.9%) and 48.76Al (99.99%) into a vacuum induction melting furnace, the melting temperature is 1500 ℃, protected under He atmosphere, The volatilization of Mg was suppressed to obtain an ingot, which was crushed and passed through a 300-mesh sieve to obtain a powder sample. Put the powder sample into the ball mill tank, ball mill for 10-15h, the ball-to-material ratio is 35:1, and the ball mill rotates at 300-350rpm. Before the ball mill treatment, it is necessary to fill the tank with Ar to avoid excessive oxidation of the alloy powder, and the ball mill ends. 5wt.%Fe@C and 5wt.%CrF were then added to it 3 , Repeat the above steps, ball mill 2±1h.

[0057] For the Mg obtained above 90 Al 5 Y 5 +5wt.%5wt.%Fe@C+5wt.%CrF 3 Activation treatment is carried out, the conditions are 320-360 ° C, hydrogen absorption under the hydrogen pressure of 3-3.5 MPa, hydrogen desorption at 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com