Low-temperature high-capacity Mg-RE-Ni-based A2B-type hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy, mg-re-ni technology, applied in the field of high-capacity Mg-RE-Ni-based A2B type hydrogen storage alloy and its preparation, can solve the problems of poor hydrogen absorption and desorption cycle stability, and achieve improved hydrogen absorption and desorption Effects of kinetic properties, surface activity improvement, and cycle stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

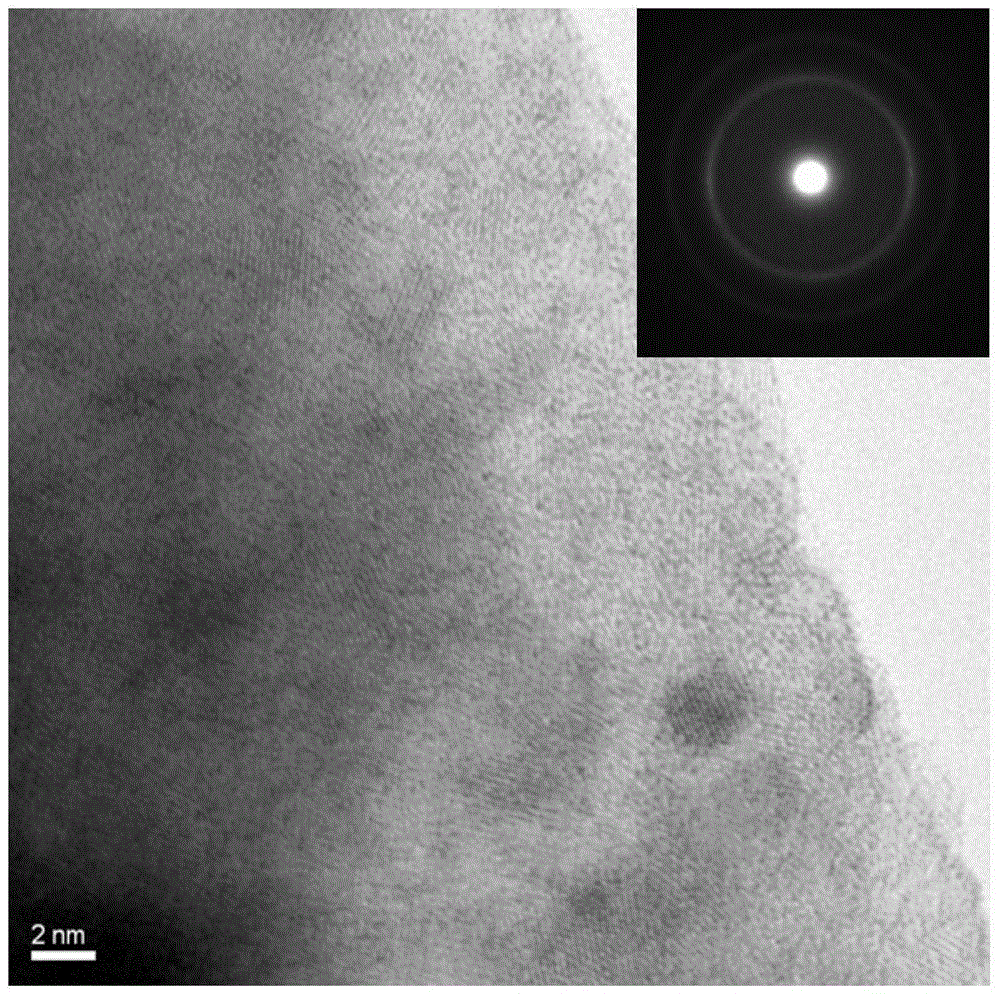

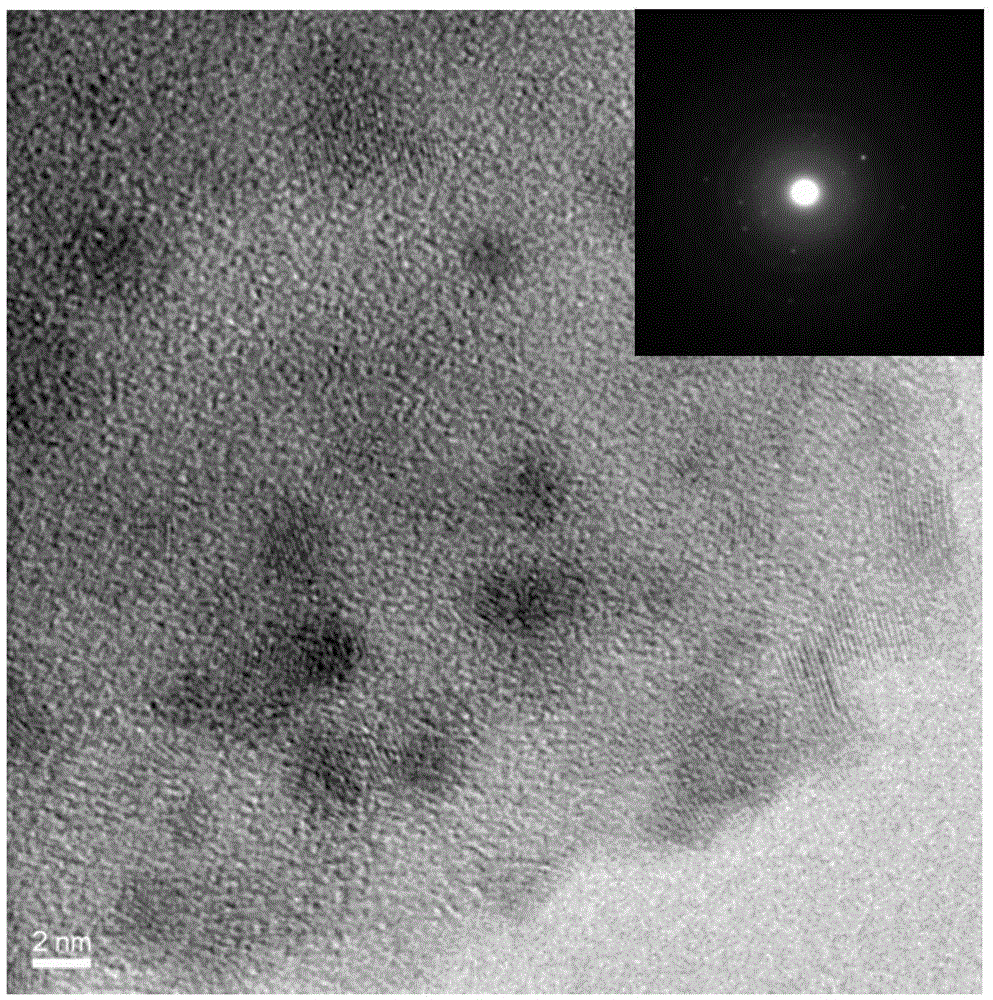

[0032] The invention provides a low-temperature high-capacity Mg-RE-Ni-based A 2 The preparation method of type B hydrogen storage alloy comprises the steps:

[0033] (1) Raw material preparation: according to the chemical formula Mg 25-x RE x Ni 10-y-z Ti y al z Dosing, where RE is at least one of the rare earth elements lanthanum, cerium, praseodymium, neodymium, samarium, and yttrium; x, y, and z are atomic ratios, 1<x<5, 1<y<3, 0.2<z <1, preferably x=3, y=2, z=0.6; the magnesium and rare earth in the composition of the chemical formula increase the burning loss by 5%-10% when proportioned, and the metal purity of the raw material is more than or equal to 99.5%.

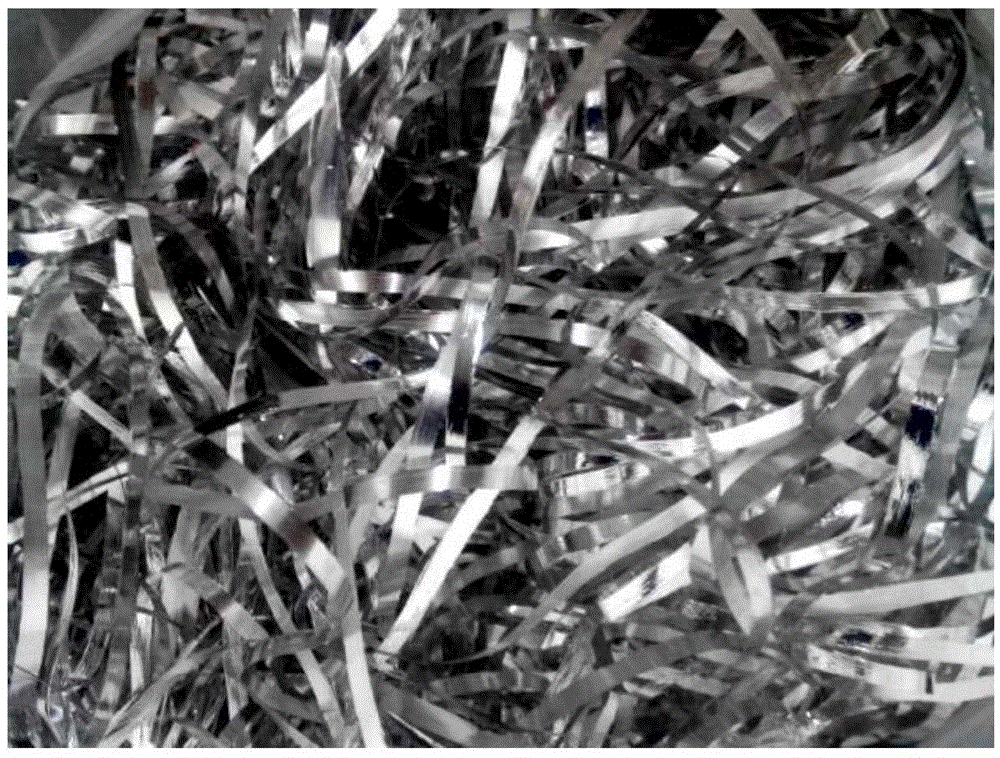

[0034] (2) Smelting: The raw materials weighed in step (1) are smelted in a vacuum induction furnace, and the vacuum is first evacuated to 1×10 -2 -5×10 -5Pa, then pass in an inert gas of 0.01-0.1MPa as a protective gas, the protective gas is pure helium or helium+argon mixed gas, the volume ratio of the mi...

Embodiment 1

[0041] Example 1: Mg 22 Y 3 Ni 7.4 Ti 2 Al 0.6

Embodiment 2

[0042] Example 2: Mg 24 La 1 Ni 8.8 Ti 1 Al 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com