Ti-Cr-V solid solution alloy with high weight of hydrogen and low V content

A solid solution and hydrogen storage technology, applied in the field of Ti-Cr-V solid solution alloy, can solve the problems of complex optimization selection, high alloy cost, increased processing cost, etc., to improve hydrogen storage capacity, simplify preparation process, and reduce material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

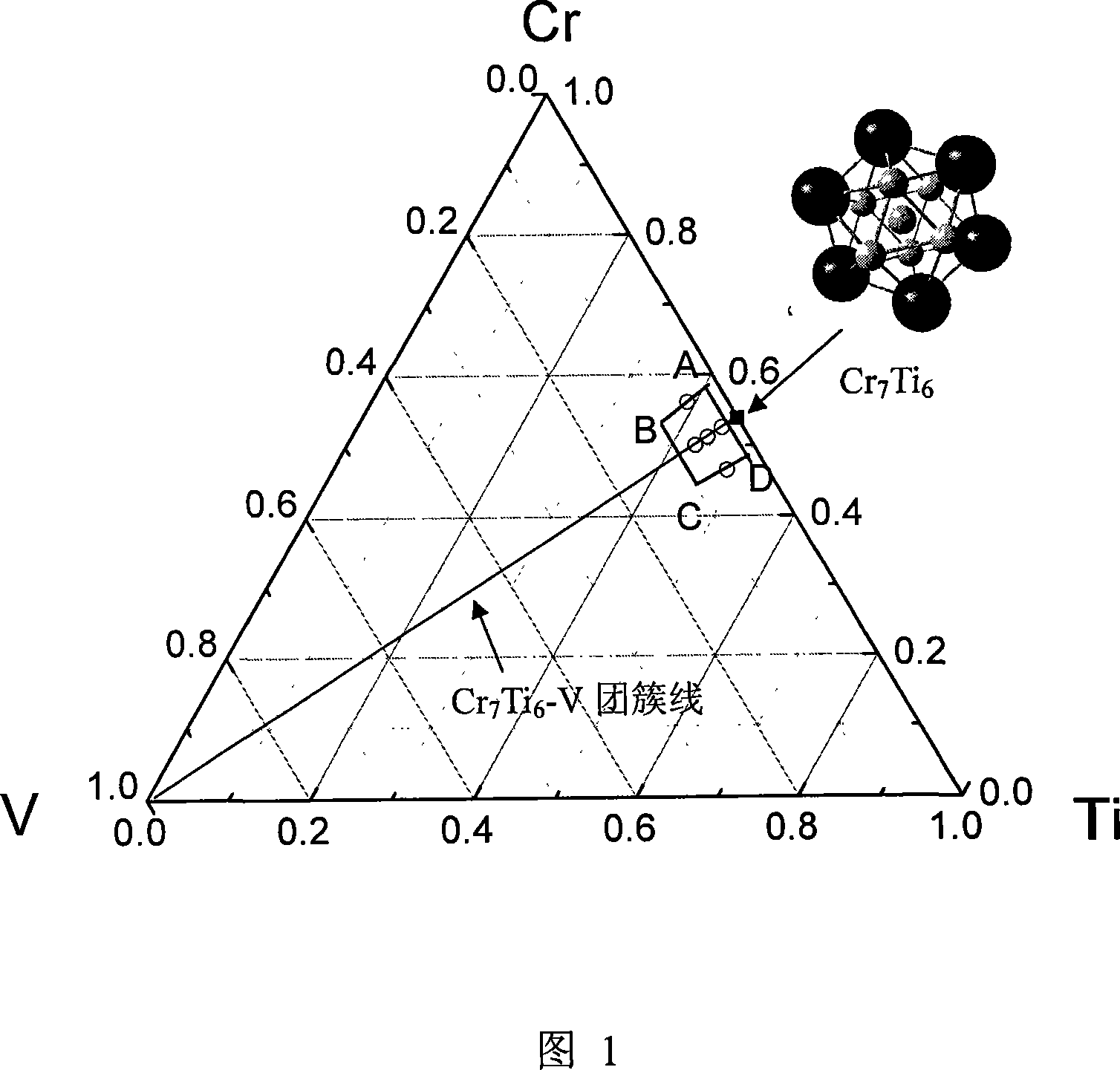

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one, Ti 48.5 Cr 46.5 V 5 Preparation of Solid Solution Alloy and Its Hydrogen Storage Properties

[0031] Ti 48.5 Cr 46.5 V 5 Alloy composition converted to design composition weight percentage Ti 46.5 Cr 48.4 V 5.1 , Weigh the raw materials of pure metal Ti, Cr and V with a purity of 99.9% according to this ratio; Turn it over and smelt it repeatedly at least 3 times to obtain an alloy ingot with uniform composition; then use the copper mold suction casting method to obtain an alloy rod with a diameter of 3mm; use an X-ray diffractometer (Cu Kα radiation, its wavelength λ=0.15406nm) to analyze the alloy The phase structure of the rod was confirmed to be the solid solution structure of BCC-V; the alloy rod was mechanically ground into powder with a particle size of less than 300 μm, the sample was placed in a stainless steel reaction vessel, and it was activated with P-C-T hydrogen absorption and desorption test equipment. Vacuum at K for 30 minutes,...

Embodiment 2

[0032] Embodiment two, Ti 45 Cr 52.5 V 2.5 Preparation of Solid Solution Alloy and Its Hydrogen Storage Properties

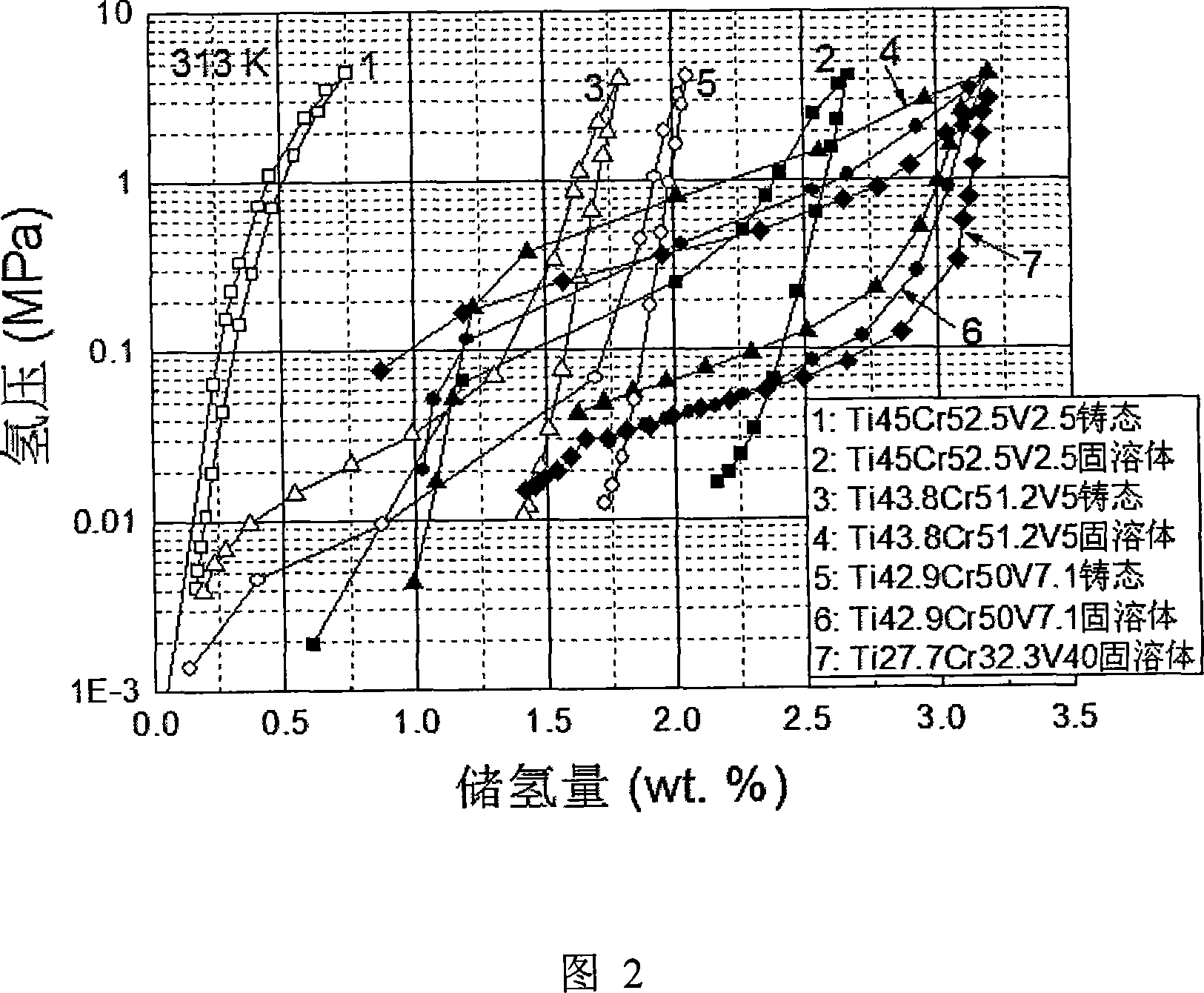

[0033] Ti 45 Cr 52.5 V 2.5 Alloy composition converted to design composition weight percentage Ti 43 Cr 54.5 V 2.5 , weigh the raw material of 99.9% pure metal Ti with a purity of 99.9%, Cr and V in this ratio; then adopt non-consumable arc melting and copper mold suction casting, the method is the same as that of Example 1; analyze the alloy bar with X-ray diffractometer The phase structure of BCC-V is confirmed as the solid solution structure of BCC-V; the activation treatment and hydrogen absorption and desorption behavior test steps are the same as in Example 1 with P-C-T hydrogen absorption and desorption test equipment, and the maximum hydrogen storage capacity of the alloy measured is 2.7 wt.%.

Embodiment 3

[0034] Embodiment three, Ti 43.8 Cr 51.2 V 5 Preparation of Solid Solution Alloy and Its Hydrogen Storage Properties

[0035] Ti 43.8 Cr 51.2 V 5 Alloy composition converted to design composition weight percentage Ti 41.9 Cr 53 V 5.1 , weigh the raw material of 99.9% pure metal Ti with a purity of 99.9%, Cr and V in this ratio; then adopt non-consumable arc melting and copper mold suction casting, the method is the same as that of Example 1; analyze the alloy bar with X-ray diffractometer The phase structure of BCC-V is confirmed as the solid solution structure of BCC-V; the activation treatment and hydrogen absorption and desorption behavior test steps are the same as in Example 1 with P-C-T hydrogen absorption and desorption test equipment, and the maximum hydrogen storage capacity of the alloy measured is 3.2 wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com