Lithium niobate-doped modified Mg-based hydrogen storage material and preparation method thereof

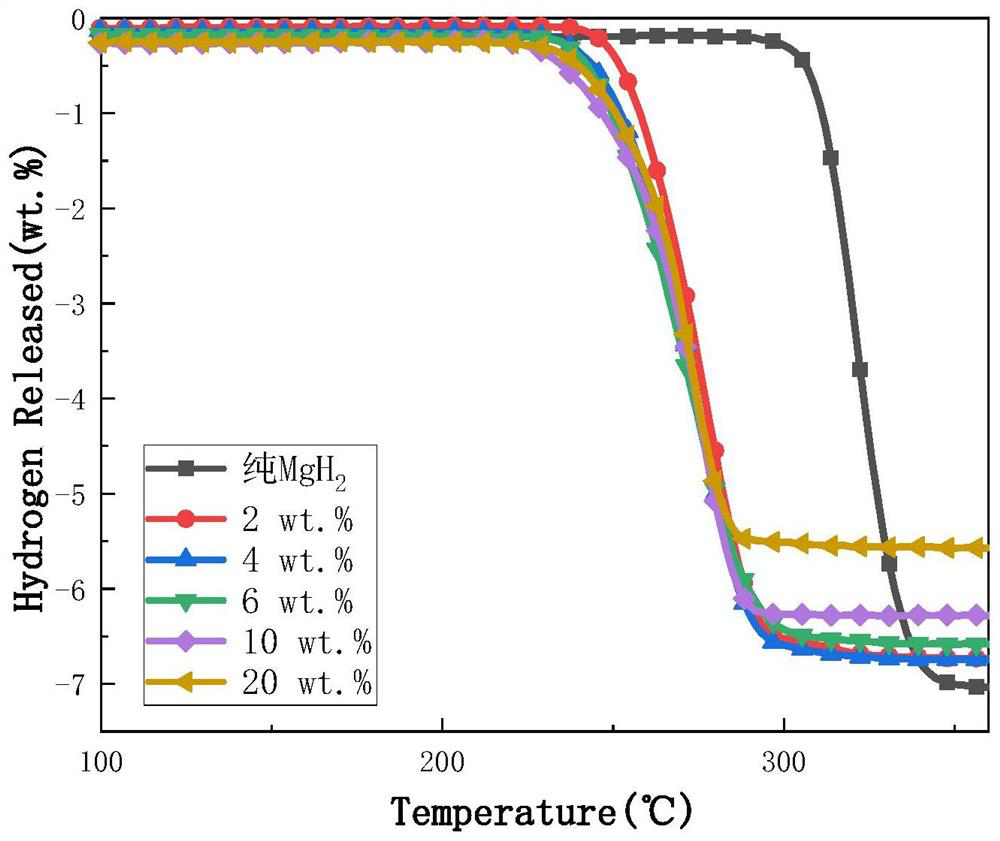

A hydrogen storage material, lithium niobate technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problem of lack of relevant research and reports on the catalytic performance of magnesium-based hydrogen storage materials, high gasification and liquefaction costs, and hydrogen leakage. and other problems, to achieve the effect of improving the kinetic performance of hydrogen absorption and desorption, improving the kinetic performance of hydrogen absorption and desorption, and balancing the loss of hydrogen storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further elaborated below in conjunction with the examples, and the following preparation methods are only intended to illustrate the present invention, rather than to limit the scope of the present invention. Unless otherwise specified, the following metal raw materials can be purchased in the market, and the preparation methods and testing methods adopted in the following examples all adopt the existing conventional methods.

[0028] 1. Preparation of materials

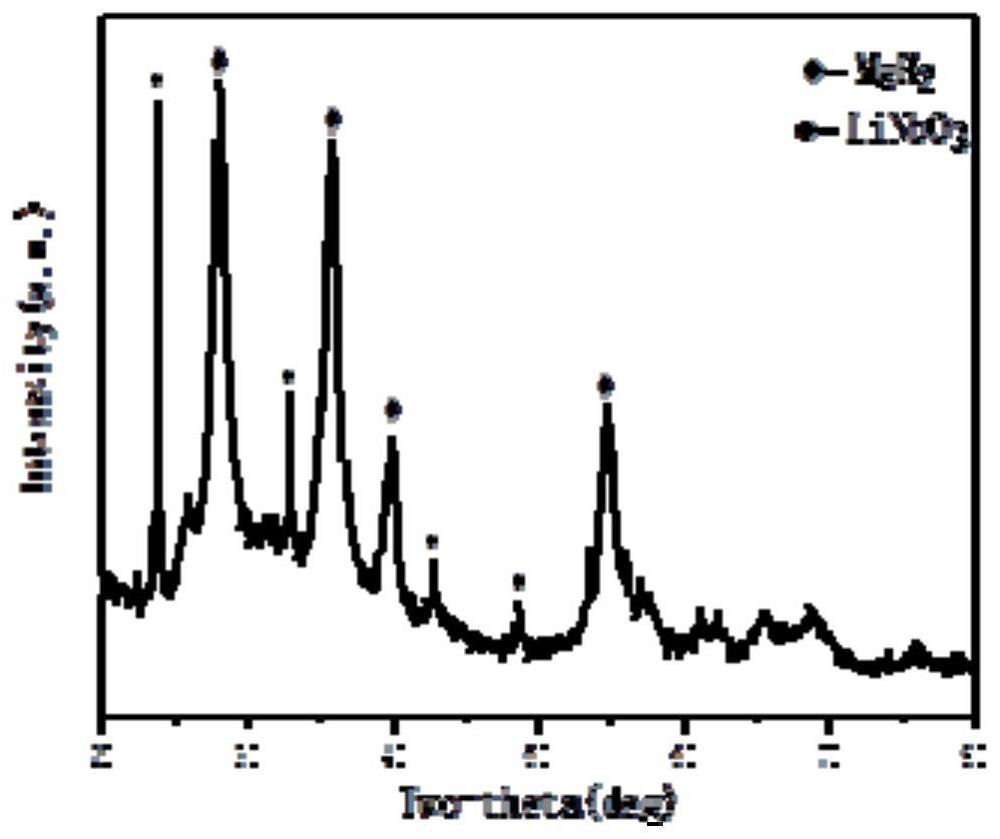

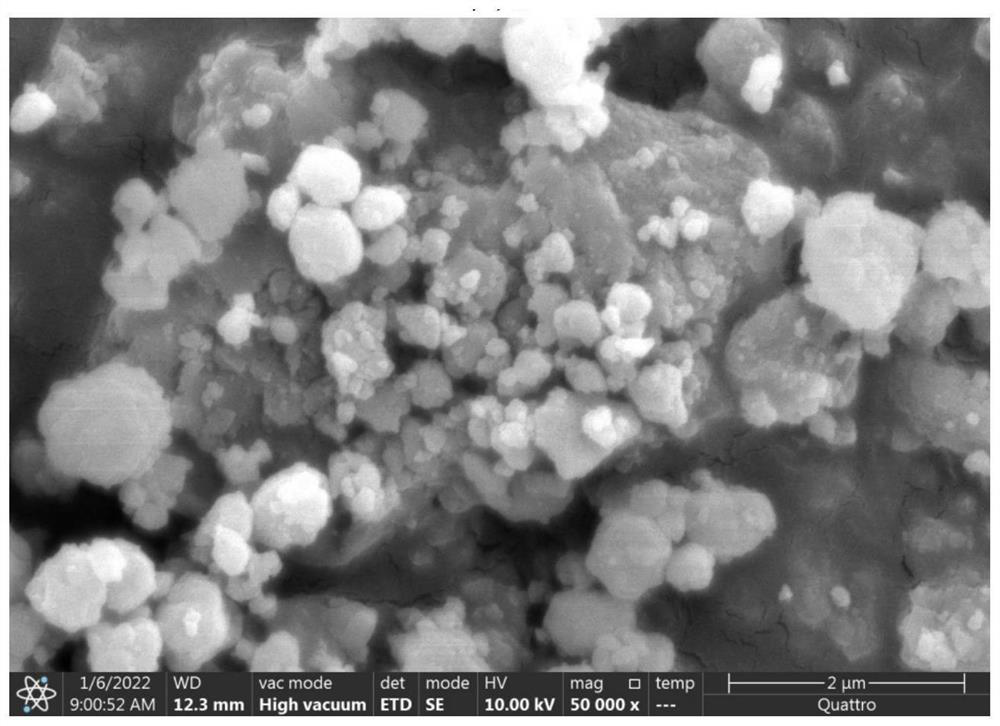

[0029] Preparation of doped LiNbO 3 MgH 2 The specific preparation steps of the hydrogen storage material are as follows:

[0030] (1) In a glove box filled with argon gas, weigh LiNbO according to the mass fraction ratio. 3 Powder and MgH 2Powder (particle size less than 25μm, purity greater than 98%). Place the weighed two powders in a 250ml stainless steel ball mill jar in a glove box, and add 8mm, 5mm and 3mm stainless steel grinding balls in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com