A magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure and its preparation method

A magnesium-based hydrogen storage alloy, long-term technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve low hydrogen absorption capacity, high dehydrogenation temperature, high hydrogen release temperature, etc. problems, achieve the effect of low hydrogen desorption temperature, large hydrogen storage capacity, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 7.79g of pure magnesium powder, 0.45g of vanadium powder, 1.71g of yttrium powder and 0.05g of lithium powder. After screening with 200 meshes, put them into a ball mill jar, and then put 150g of stainless steel balls with a diameter of 4mm for ball milling. 300r / min, run for 30min and then stop for 10min, and circulate ball milling for 30h to obtain magnesium alloy powder with an average particle size of 90nm, then put the magnesium alloy powder into a vacuum high-temperature furnace, heat to 200°C under an argon atmosphere and After 24 hours of heat preservation, a magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure was prepared.

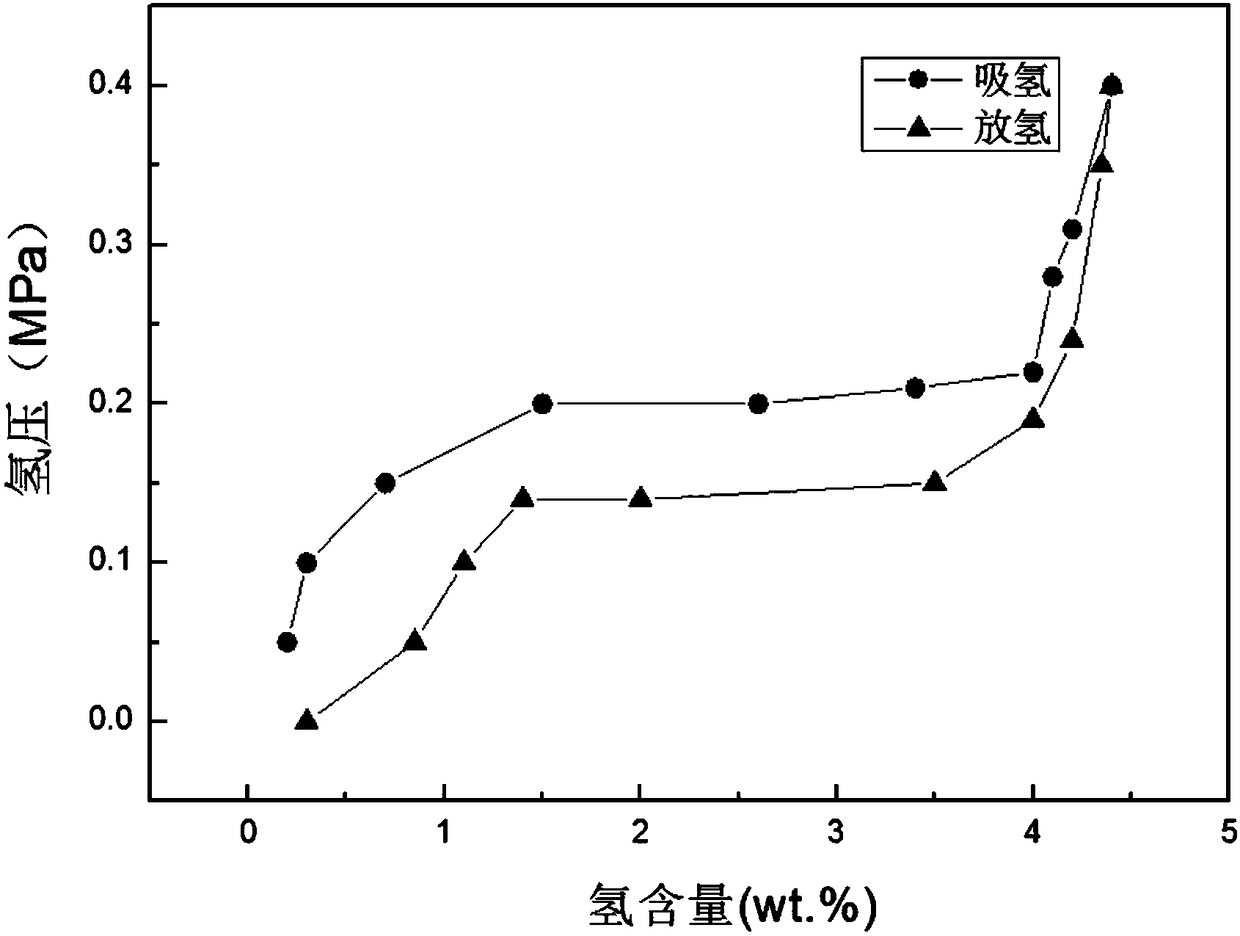

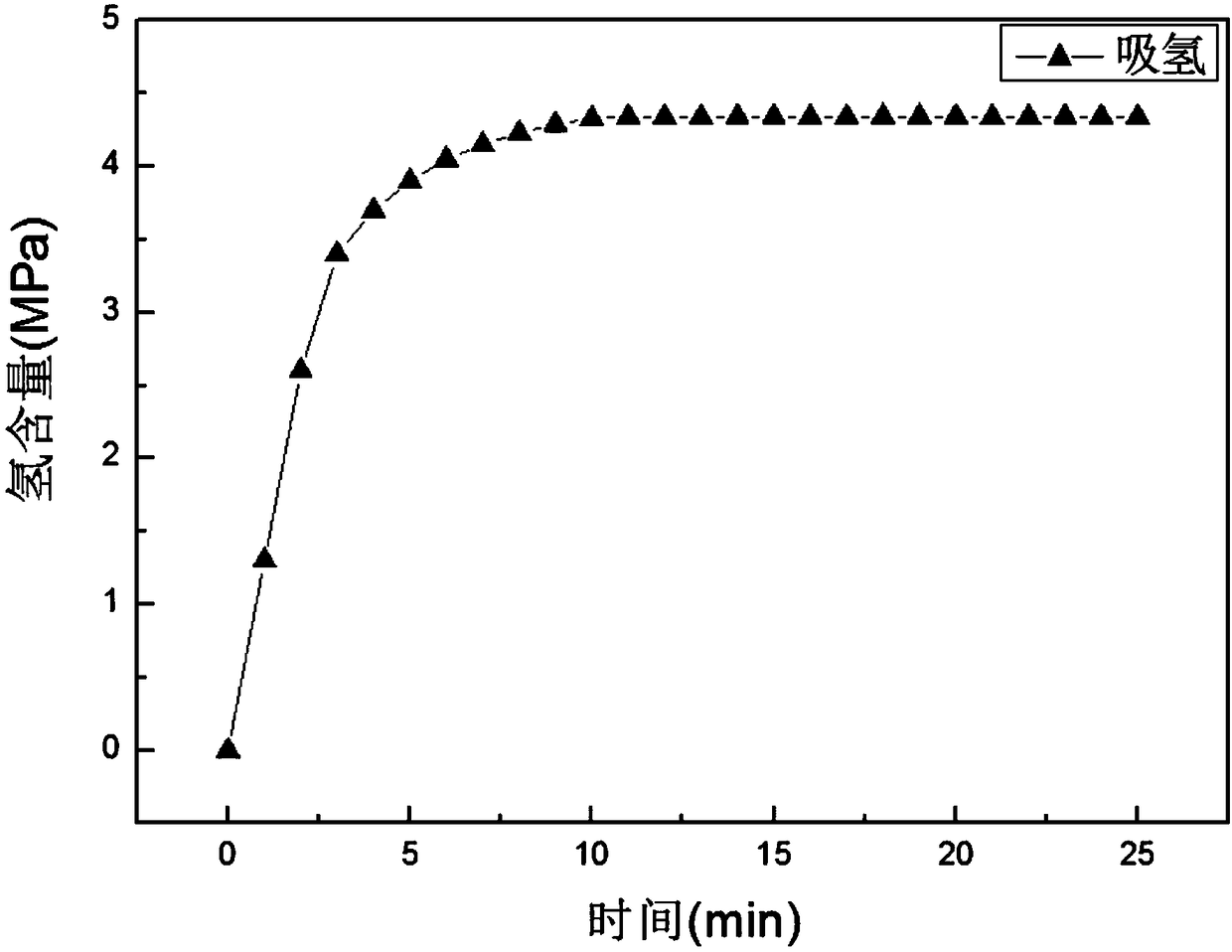

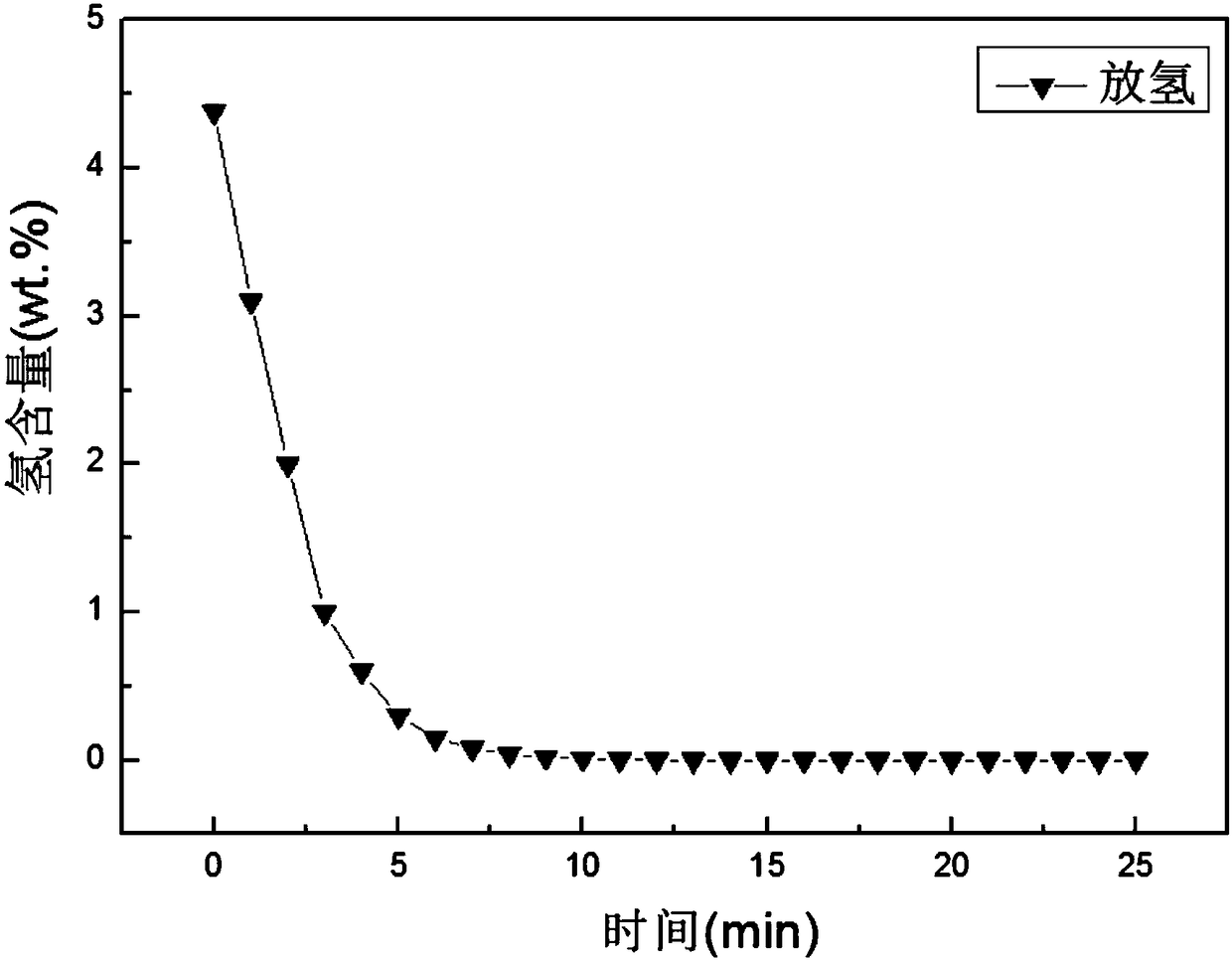

[0020] Take 1g of the above-mentioned magnesium-based hydrogen storage alloy and put it into the sample chamber of the PCT tester, seal it and evacuate it, heat it to 200°C in a temperature-controlled electric furnace, fill it with 2MPa H2, activate it for 3 times, and start the measurement of the...

Embodiment 2

[0022] Weigh 7.68g of pure magnesium powder, 0.51g of cobalt powder, 1.71g of yttrium powder and 0.1g of lithium powder. After screening with 200 meshes, put them into a ball mill jar, and then put 200g of stainless steel balls with a diameter of 6mm for ball milling. 400r / min, run for 30min and then stop for 10min, and circulate ball milling for 50h to obtain magnesium alloy powder with an average particle size of 50nm, then put the magnesium alloy powder into a vacuum high-temperature furnace, heat to 200°C in an argon atmosphere and After 24 hours of heat preservation, a magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure was prepared.

[0023] Take 1g of the above-mentioned magnesium-based hydrogen storage alloy and put it into the sample chamber of the PCT tester, seal it and evacuate it, heat it to 200°C in a temperature-controlled electric furnace, fill it with 2MPa H2, activate it for 3 times, and start the measurement of the hydro...

Embodiment 3

[0025] Weigh 8.41g of pure magnesium powder, 0.33g of cobalt powder, 1.16g of yttrium powder and 0.1g of lithium powder. After screening with 200 meshes, put them into a ball mill jar, and then put 200g of stainless steel balls with a diameter of 6mm for ball milling. 400r / min, run for 30min and then stop for 10min, and circulate ball milling for 50h to obtain magnesium alloy powder with an average particle size of 50nm, then put the magnesium alloy powder into a vacuum high-temperature furnace, heat to 200°C in an argon atmosphere and After 24 hours of heat preservation, a magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure was prepared.

[0026] Take 1g of the above-mentioned magnesium-based hydrogen storage alloy and put it into the sample chamber of the PCT tester, seal it and evacuate it, heat it to 200°C in a temperature-controlled electric furnace, fill it with 2MPa H2, activate it for 3 times, and start the measurement of the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com