Magnesium, aluminum, boron and nickel-based hydrogen storage material and preparing method thereof

A hydrogen storage material, nickel-based technology, applied in the field of hydrogen storage materials and its preparation, can solve the problems of many raw materials and high cost, and achieve the effects of large hydrogen storage capacity, short production cycle, and good hydrogen absorption and desorption kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

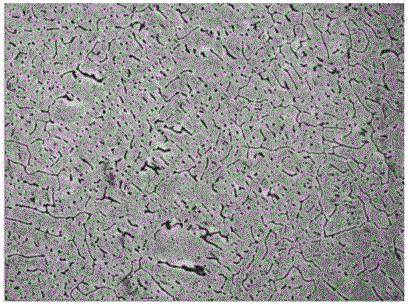

[0020] Take 2.96g of Mg powder, 0.2g of Al powder, 0.04g of B powder and 0.8g of Ni powder and mix evenly, press it into a cylinder with a diameter of 10mm and a height of 8mm, wrap it with tantalum, and then use a six-sided top press to keep the temperature at 4GPa and 1200℃. After pressing for 30 minutes, the alloy was rapidly cooled with liquid nitrogen immediately to obtain a magnesium-aluminum-boron-nickel-based hydrogen storage material. Such as figure 1 As shown, it can be seen that there are a large number of abundant secondary dendrites in the sample, which provide more channels for the diffusion of hydrogen atoms.

Embodiment 2

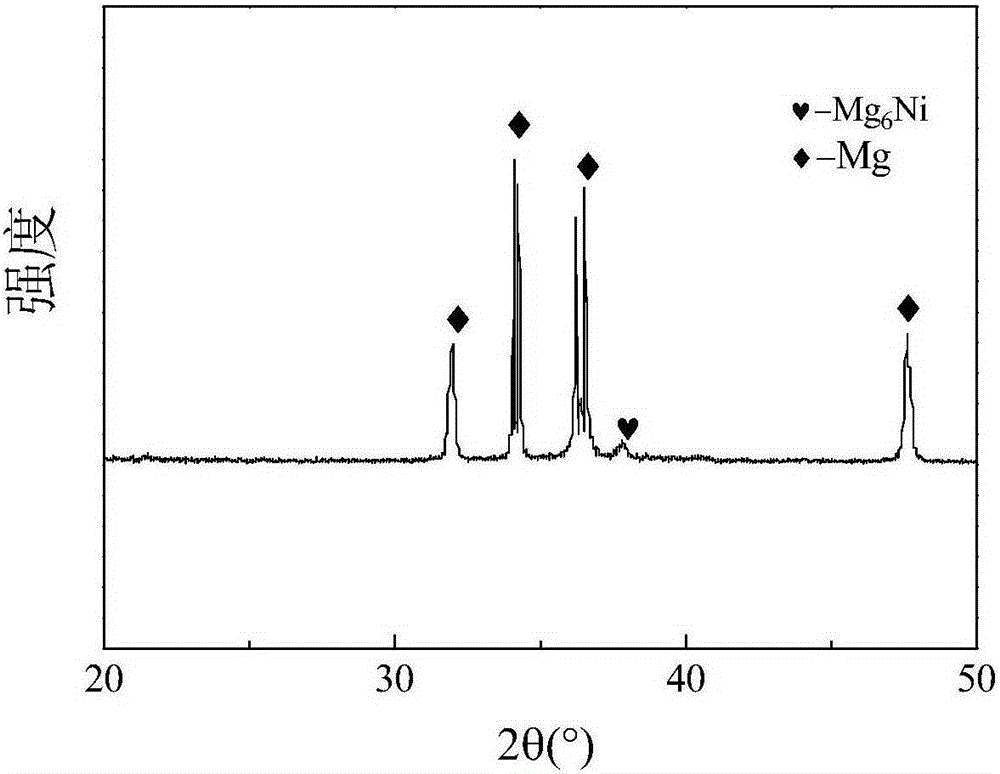

[0022] Take 3.44g of Mg powder, 0.12g of Al powder, 0.04g of B powder and 0.4g of Ni powder and mix them evenly, press them into a cylinder with a diameter of 10mm and a height of 8mm, wrap it with tantalum, and then use a six-sided top press to keep warm at 6GPa and 1800°C. After pressing for 60 minutes, the alloy was rapidly cooled with liquid nitrogen immediately to obtain a magnesium-aluminum-boron-nickel-based hydrogen storage material. Such as figure 2 As shown, it can be seen that the composition of the sample is Mg 6 Ni+Mg phase.

Embodiment 3

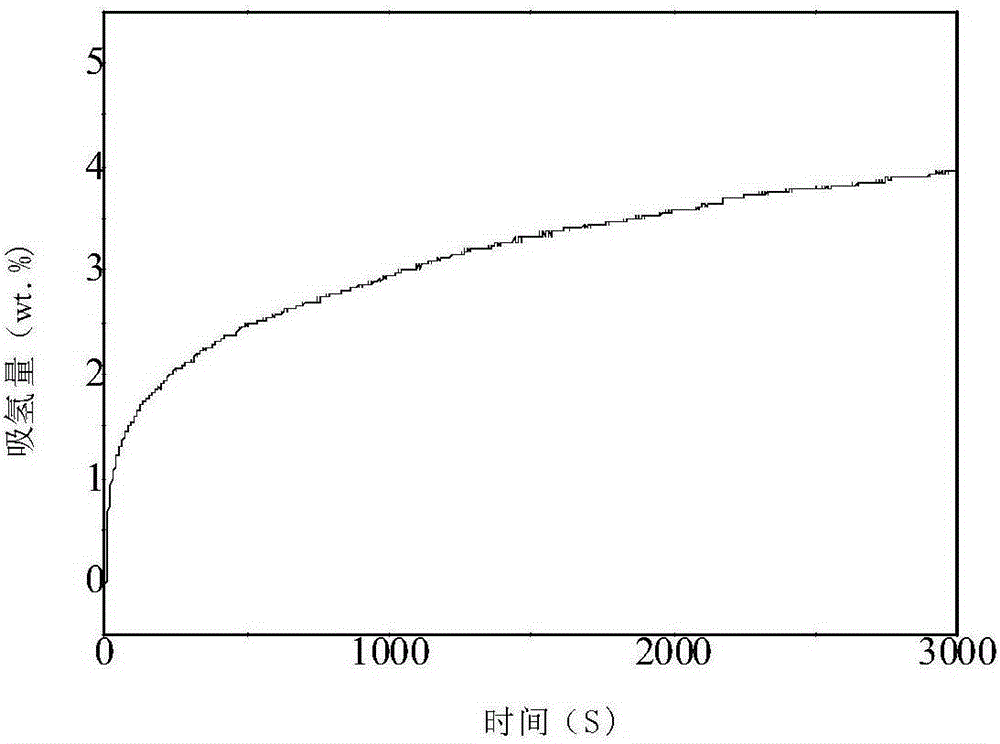

[0024] Take 3.74g of Mg powder, 0.04g of Al powder, 0.02g of B powder and 0.2g of Ni powder and mix them evenly, press them into a cylinder with a diameter of 10mm and a height of 8mm, wrap it with tantalum, and then use a six-sided top press to keep it warm at 4GPa and 1400°C. After pressing for 45 minutes, the alloy was rapidly cooled with liquid nitrogen immediately to obtain a magnesium-aluminum-boron-nickel-based hydrogen storage material. Such as image 3 As shown, it can be seen that the amount of hydrogen absorbed by the sample reaches 3.8% after 3000S at 300°C, as Figure 4 As shown, the hydrogen desorption kinetics of the sample at 300 °C within 300 S can be seen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com