Preparation method of Mg-Ni series hydrogen storage alloy

A hydrogen storage alloy and alloy powder technology, applied in the field of ion sintering technology, can solve the problems of difficult control of components, difficulty in mass production, and long sintering time, and achieve low cost, enhanced grain boundary diffusion, and good activation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

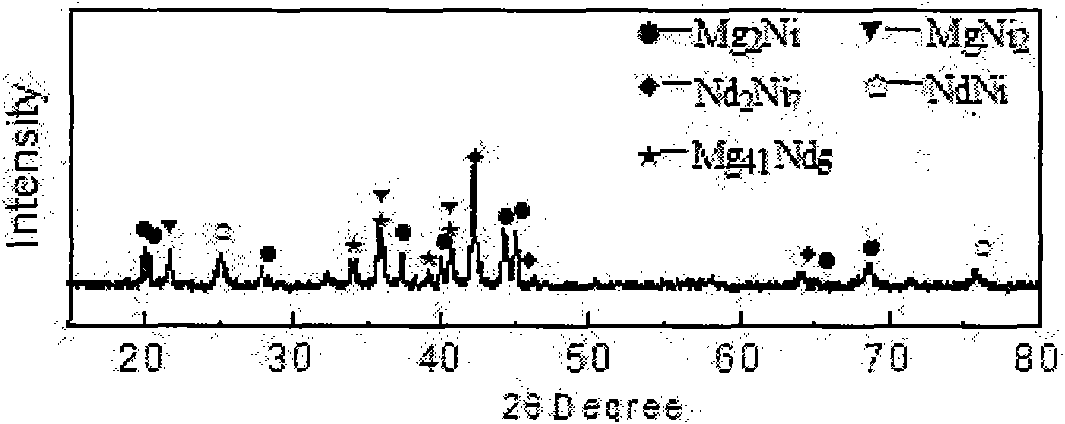

[0013] Embodiment 1: prepare Mg 1.7 Nd 0.3 Ni alloy

[0014] The raw material Mg powder Ni powder and NdNi alloy powder by Mg 1.7 Nd 0.3 The Ni ratio is weighed, and then the powder is loaded into a special SPS mold (Φ20mm) for pressing, and then the mold with the original powder is subjected to discharge plasma sintering under a vacuum atmosphere. The sintering process system is as follows: the heating rate is 100°C / min, the sintering temperature is 480°C, the pressure is 20MPa, the holding time is 5min, and then the furnace is cooled to room temperature. The XRD detection results of the alloy are as follows figure 1 It is shown that the alloy has a multiphase structure.

Embodiment 2

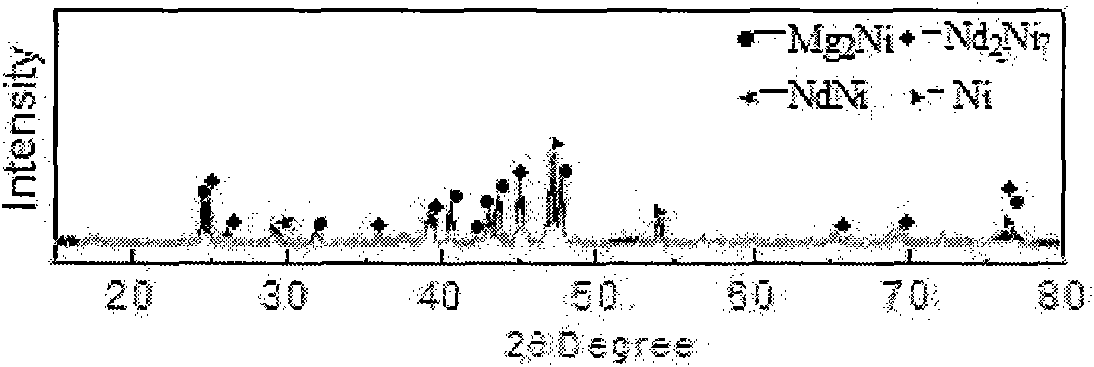

[0015] Embodiment 2: prepare Mg 1.8 Nd 0.2 Ni alloy

[0016] The raw material Mg powder Ni powder and NdNi alloy powder by Mg 1.8 Nd 0.2 The Ni ratio is weighed, and then the powder is loaded into a special SPS mold (Φ20mm) for pressing, and then the mold with the original powder is subjected to discharge plasma sintering under a vacuum atmosphere. The sintering process system is as follows: the heating rate is 100°C / min, the sintering temperature is 450°C, the pressure is 20MPa, the holding time is 5min, and then the furnace is cooled to room temperature. The XRD detection results of the alloy are as follows figure 2 It is shown that the alloy has a multiphase structure.

Embodiment 3

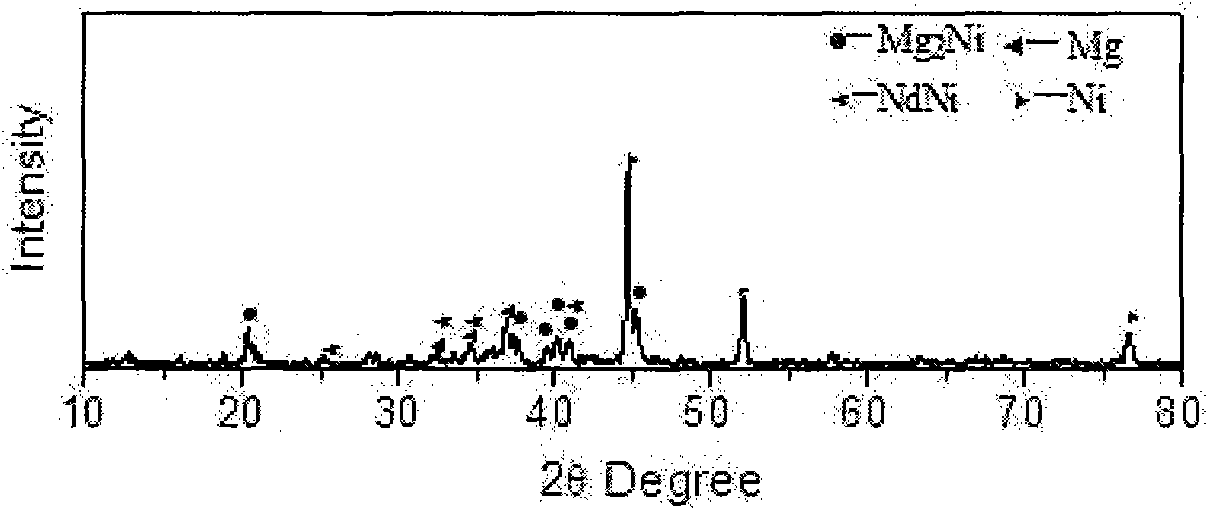

[0017] Embodiment 3: prepare Mg 1.9 Nd 0.1 Ni alloy

[0018] The raw material Mg powder Ni powder and NdNi alloy powder by Mg 1.9 Nd 0.1 The Ni ratio is weighed, and then the powder is loaded into a special SPS mold (Φ20mm) for pressing, and then the mold with the original powder is subjected to discharge plasma sintering under a vacuum atmosphere. , The sintering process system is: the heating rate is 100°C / min, the sintering temperature is 430°C, the pressure is 20MPa, the holding time is 5min, and then the furnace is cooled to room temperature. The XRD detection results of the alloy are as follows image 3 It is shown that the alloy has a multiphase structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com