Nano-structure block magnesium material and preparation method thereof

A nanostructure, bulk material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as increasing the thermal diffusion time of hydrogenation/dehydrogenation reactions and reducing the heat transferability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

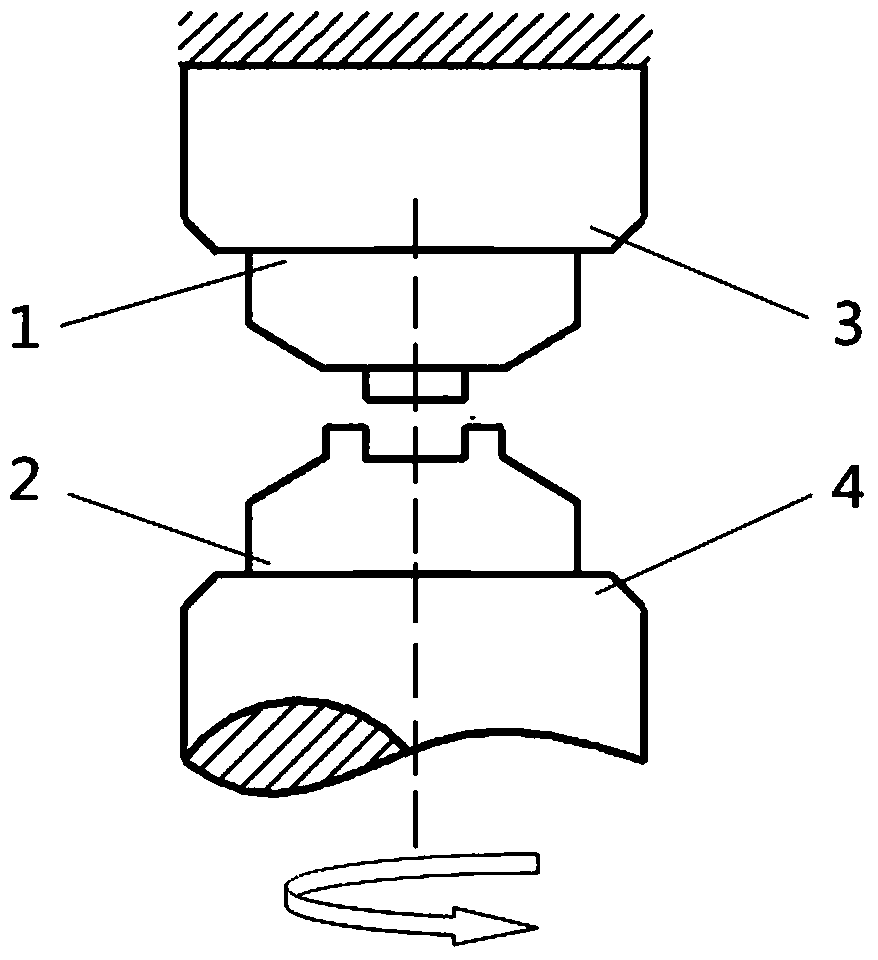

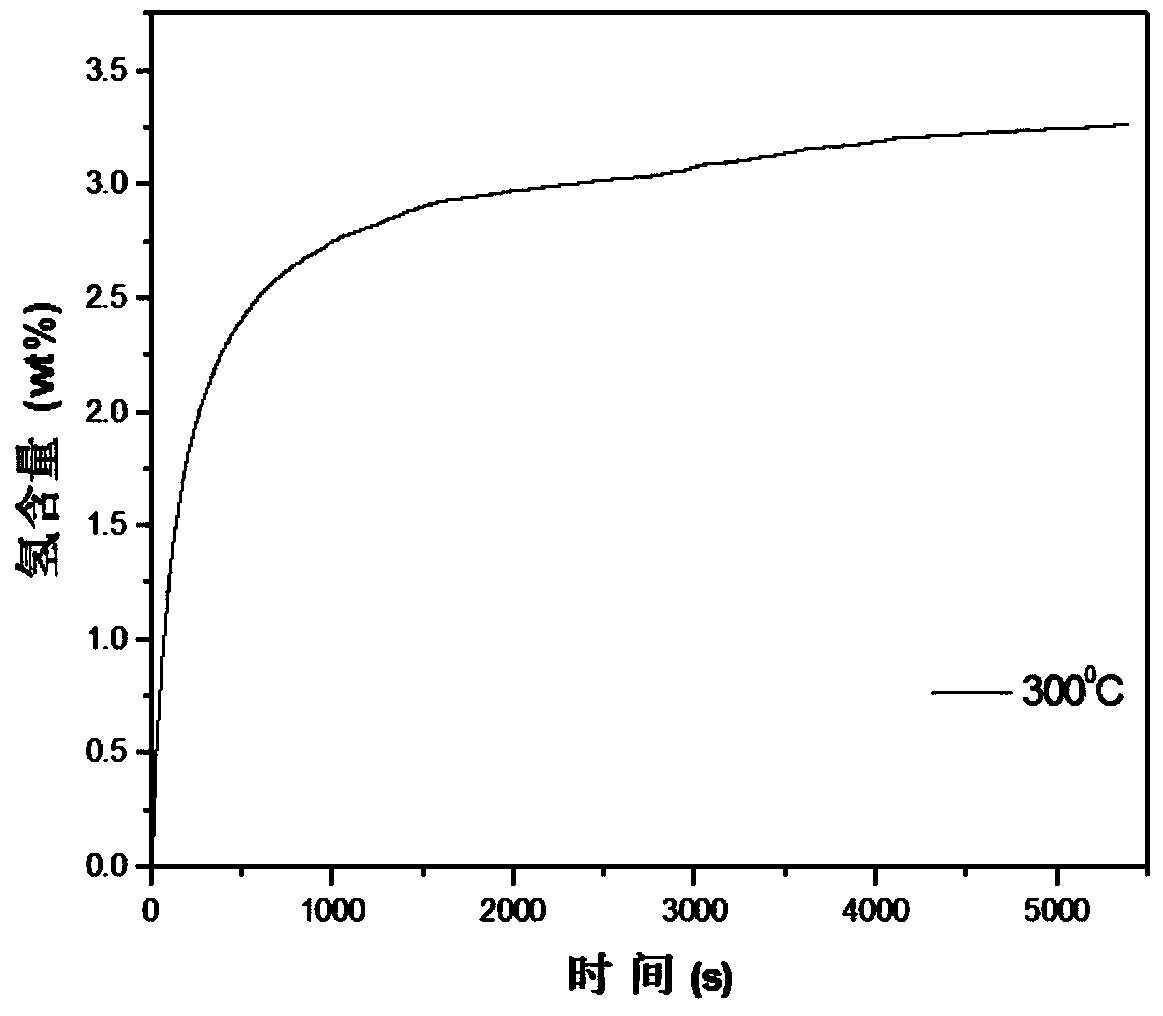

[0037] The high-purity magnesium used in this experiment was purchased commercially, with a purity of more than 99.9%. The magnesium block was cut into regular blocks with a length of 4cm × width 4cm × height 2cm with a grinding wheel cutter, and a sand mill was used to remove the oxide layer on the surface of the magnesium block. used as anode. The preparation of nanostructured bulk magnesium materials is mainly divided into two steps: (1) preparation of magnesium nanopowder by direct current arc method; (2) preparation of bulk magnesium materials by high pressure torsion method.

[0038] Step (1): A method for preparing magnesium nanopowder: a high-purity magnesium metal block is used as an anode, and a tungsten rod is used as a cathode and placed in a DC arc plasma device. When the equipment is evacuated to 5×10 -2Pa, filled with argon to 0.7atm, and then filled with 0.1atm hydrogen. Through cooling water, the water temperature is controlled at room temperature, and the w...

Embodiment 2

[0041] In this experiment, high-purity iron and high-purity magnesium are commercially purchased, and the purity reaches more than 99.9%. Similar to Example 1, the magnesium block and iron block are cut into regular blocks with a length of 4cm × width 4cm × height 2cm with a grinding wheel cutter, and The sand mill removes the oxide layer on the surface of the block, which is used as an anode. The experiment mainly includes three steps: (1) preparation of magnesium nanopowder; (2) preparation of iron nanopowder; (3) preparation of iron-containing bulk magnesium material. The preparation of the magnesium nanopowder is basically the same as in Example 1, and the specific operation can refer to the relevant part of Example 1, and the steps (2) and (3) will be mainly described below.

[0042] Step (2): A preparation method of iron nanopowder: a high-purity iron metal block is used as an anode, and a tungsten rod is used as a cathode and placed in a DC arc plasma device. When the ...

Embodiment 3

[0046] In this experiment, high-purity nickel and high-purity magnesium are commercially purchased, and the purity reaches more than 99.9%. Similar to Example 1, the magnesium block and the nickel block are cut into long 4cm * wide 4cm * high 2cm regular blocks with a grinding wheel cutter, and sand The mill removes the oxide layer on the surface of the block, which is used as an anode. The experiment mainly includes three steps: (1) preparation of magnesium nanopowder, (2) preparation of iron nanopowder; (3) preparation of nickel-containing bulk magnesium material. The preparation of the magnesium nanopowder is basically the same as in Example 1, and the specific operation can refer to the relevant part of Example 1, and the steps (2) and (3) will be mainly described below.

[0047] Step (2): A preparation method of nickel nanopowder: a high-purity nickel metal block is used as an anode, and a tungsten rod is used as a cathode and placed in a DC arc plasma device. When the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com