Fuel cell hydrogen cycle test system

A test system and fuel cell technology, applied in fuel cells, fuel cell control, fuel cell additives, etc., can solve problems such as unsatisfactory overall power consumption and simple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

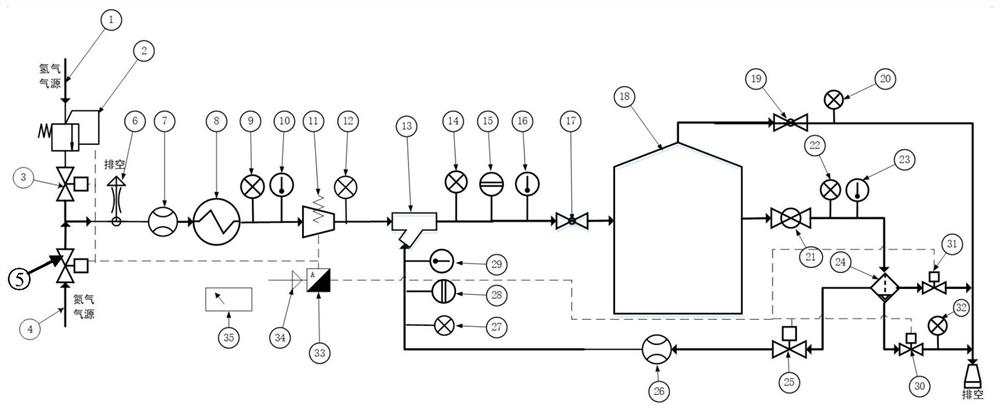

[0042] figure 1 A fuel cell hydrogen cycle test system of this embodiment is shown. It includes a hydrogen gas source 1, a dry hydrogen heat exchanger 8, a hydrogen circulation device 13, a heating and humidifying device 18, a first gas pipeline, a second gas pipeline, a third gas pipeline, an emptying pipeline, and a return pipe road. The hydrogen gas source 1 and the inlet of the dry hydrogen heat exchanger 8 are connected by a first gas pipeline, and the outlet of the dry hydrogen heat exchanger 8 is connected with the hydrogen inlet of the hydrogen circulation device 13 by a second gas pipeline. The hydrogen outlet of the circulation device 13 is connected to the inlet of the heating and humidifying device 18 through a third gas pipeline, the first outlet of the heating and humidifying device 18 is connected to the emptying pipeline, and the second outlet of the heating and humidifying device 18 is connected to the exhaust pipeline. The reflux inlets of the hydrogen circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com