Double-injection-molding feeding foaming thick-sole shoe material with inner ribs

A double-injection, material-belt technology, applied in the field of chemical processing, can solve the problems of insufficient operation stability of multiple types of polymers of the same quality, affecting the ejection efficiency of injection molds, and product overflow and plugging die-casting. performance and stability, improve the effect of protective operation, improve the effect of durability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

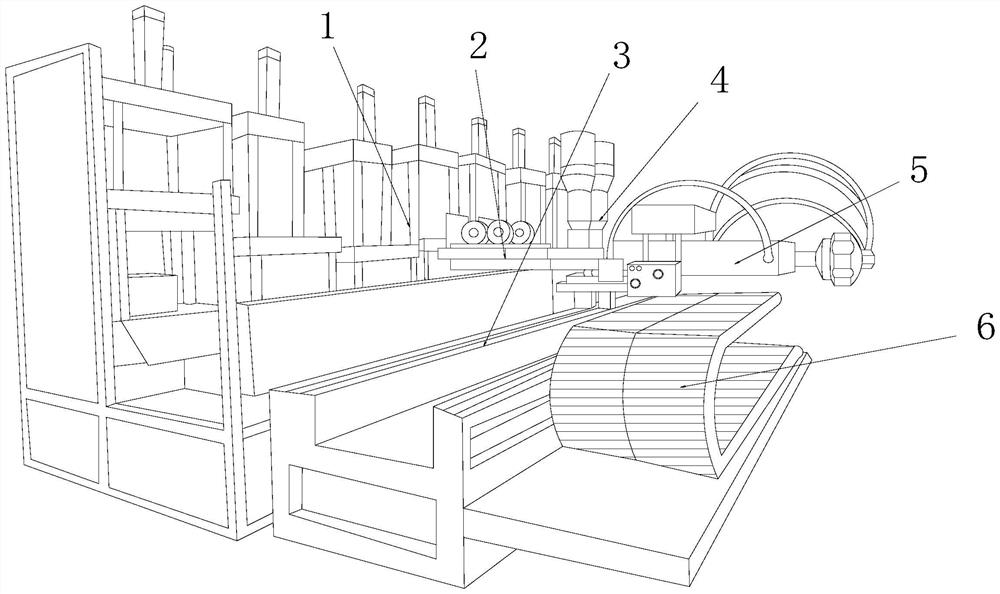

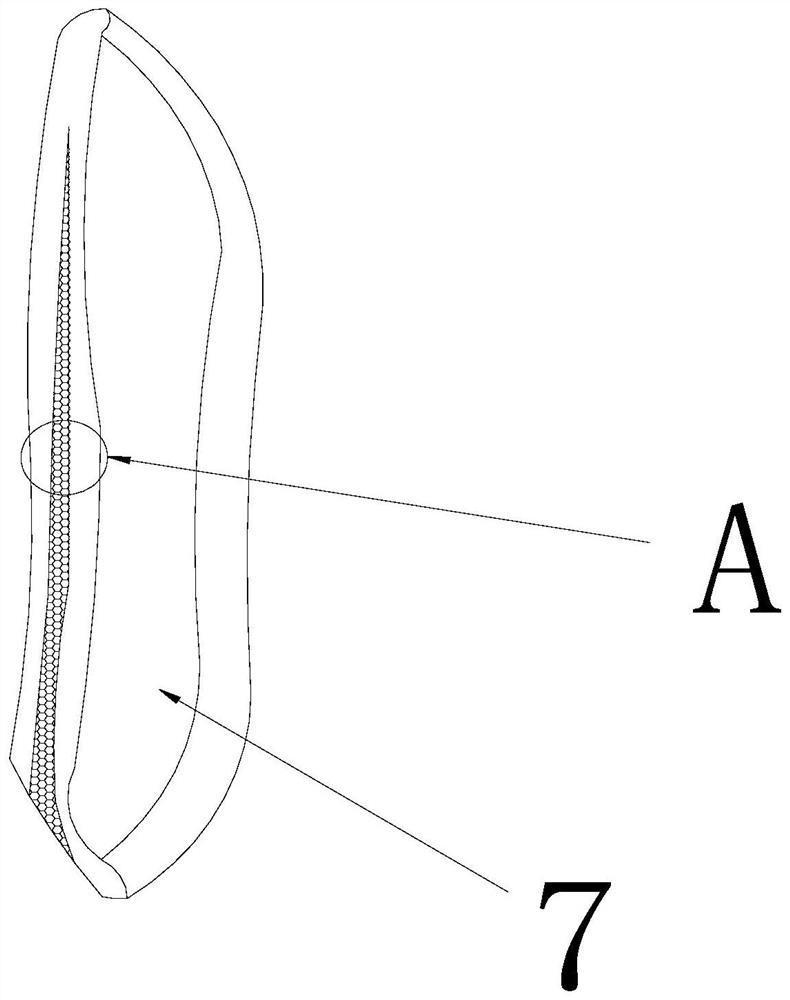

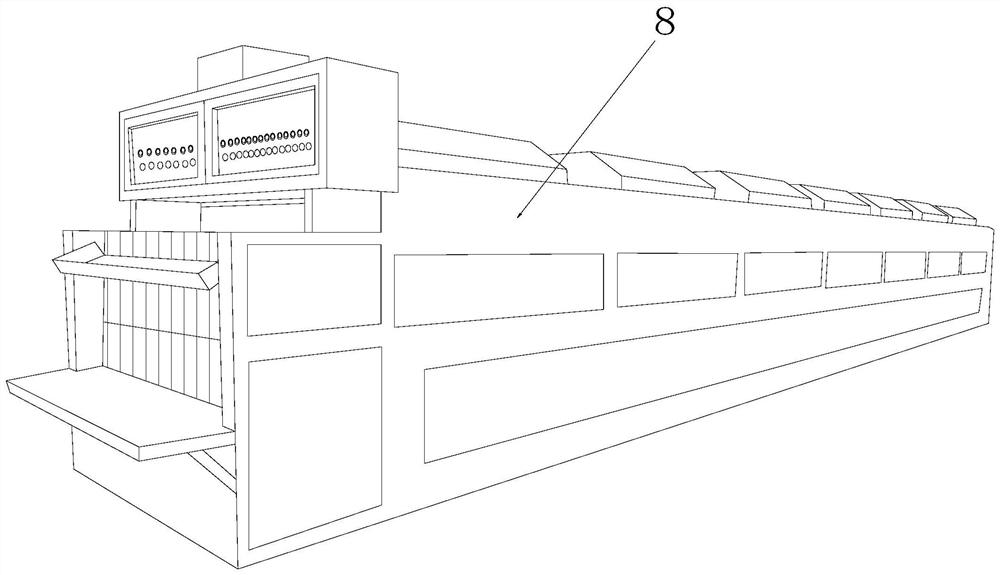

[0030] see Figure 1-Figure 7 , the present invention provides a double-injection-molded foamed thick-soled shoe material with inner ribs, the structure of which includes: a hydraulic mold frame 1, a double-injection frame 2, a rail bar frame 3, a lower hopper trough 4, a pressurized push Machine 5, chain belt body 6, interlayer shoe sole block 7, baking cabinet 8, the double injection molding frame 2 is nested on the left side of the pressurized pusher 5 and the axes are collinear, and the lower hopper tank 4 is inserted Embedded in the upper left corner of the booster pusher 5 and interpenetrated with each other, the booster pusher 5 is mechanically connected with the chain belt body 6, the booster pusher 5 is installed on the top of the rail bar groove frame 3 and is perpendicular to each other, The hydraulic mold frame 1 is nested on the left side of the double injection molding frame 2 and communicates with each other. The sandwich shoe sole block 7 is installed inside th...

Embodiment 2

[0035] see Figure 1-Figure 7 , the present invention provides a double-injection-molded foamed thick-soled shoe material with inner ribs, the other aspects are the same as in Example 1, the difference is that:

[0036] see Figure 4 , the hydraulic mold frame 1 is composed of an upper parting surface block 11, a hydraulic piston rod 12, a shoe mold pressure groove 13, a base plate 14, and a lower parting surface block 15, and the upper parting surface block 11 is nested in On the top of the hydraulic piston rod 12 and perpendicular to each other, the hydraulic piston rod 12 is inserted on the top of the shoe mold pressure groove 13, and the shoe mold pressure groove 13 is installed on the top of the base plate 14, the base The seat plate 14 is closely attached to the top surface of the lower parting surface block 15 and is on the same level, and the shoe mold pressure groove 13 is matched with the mold groove on the base plate 14 to accommodate the injection molding liquid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com