Pipeline assembly and construction method of pipeline assembly

A pipeline component and pipeline technology, which is applied in pipeline support, pipeline protection, pipeline laying and maintenance, etc., can solve the problems of unfavorable pipeline stability, weak pipeline constraints, and easy shaking, etc., so as to improve convenience, improve service life, The effect of slowing down the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

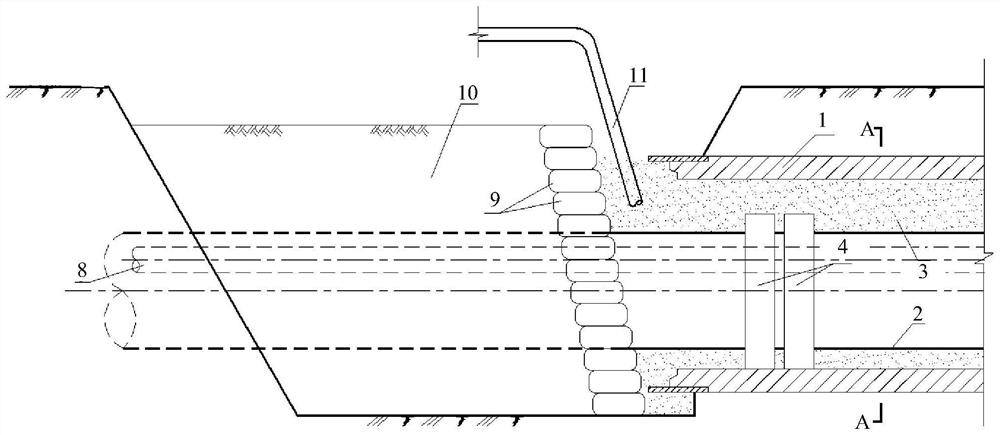

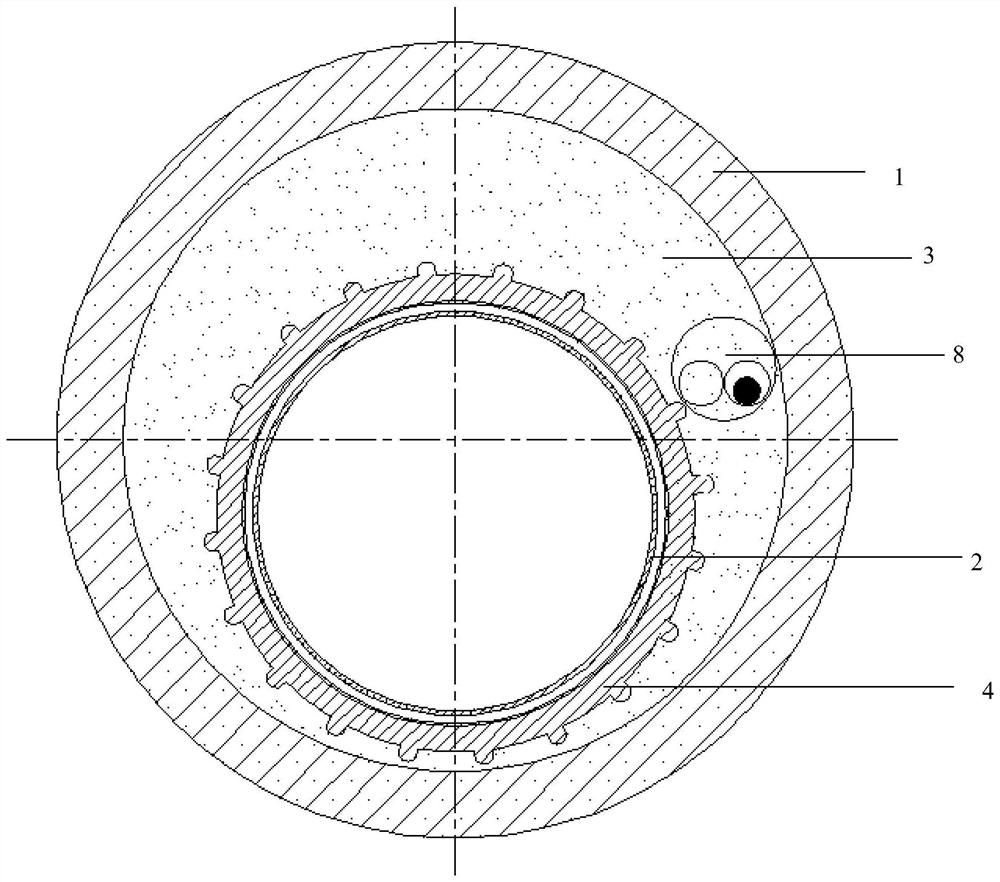

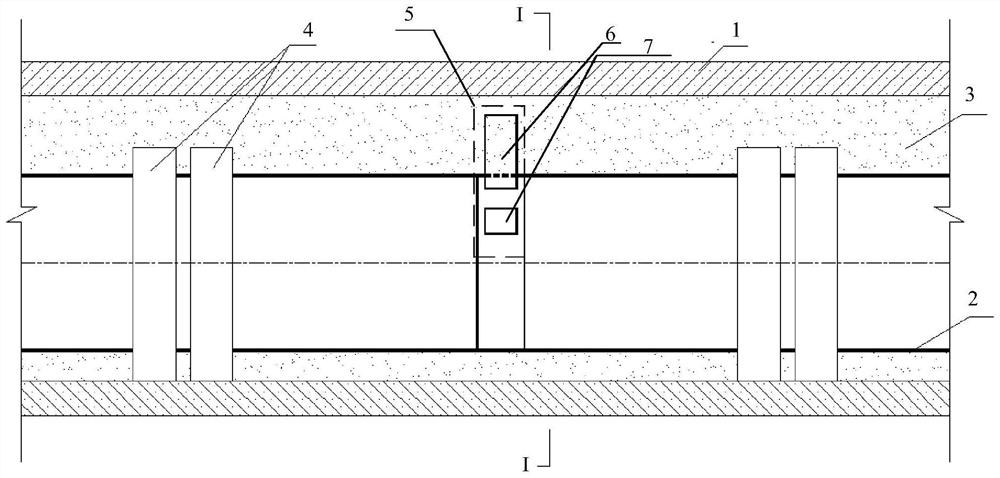

[0041] combined reference Figure 1 to Figure 4 , which shows a schematic structural diagram of the pipeline assembly provided by the embodiment of the present application. The pipeline assembly may include: a casing 1 and a pipeline 2 .

[0042] figure 1 is a schematic longitudinal section of the pipeline assembly provided by the embodiment of the present application, from figure 1 It can be seen that the pipe 2 is located in the casing 1 , and a hollow cavity 3 is formed between the pipe 2 and the casing 1 .

[0043] In a possible implementation manner, the casing 1 includes any one of the following: reinforced concrete casing, steel pipe. The sleeve 1 can be used to protect the pipeline 2 or to facilitate the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com