High thermal conductivity geothermal energy heat exchange tunnel system and its construction method

A technology with high thermal conductivity and geothermal energy, applied in heat exchange equipment, tunnels, geothermal energy, etc., can solve the problems of increasing construction difficulty, high requirements for water pumps, and affecting tunnel water stop, so as to improve the problem of linear heat sources and reduce the Uniform temperature difference stress and deformation, strong engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

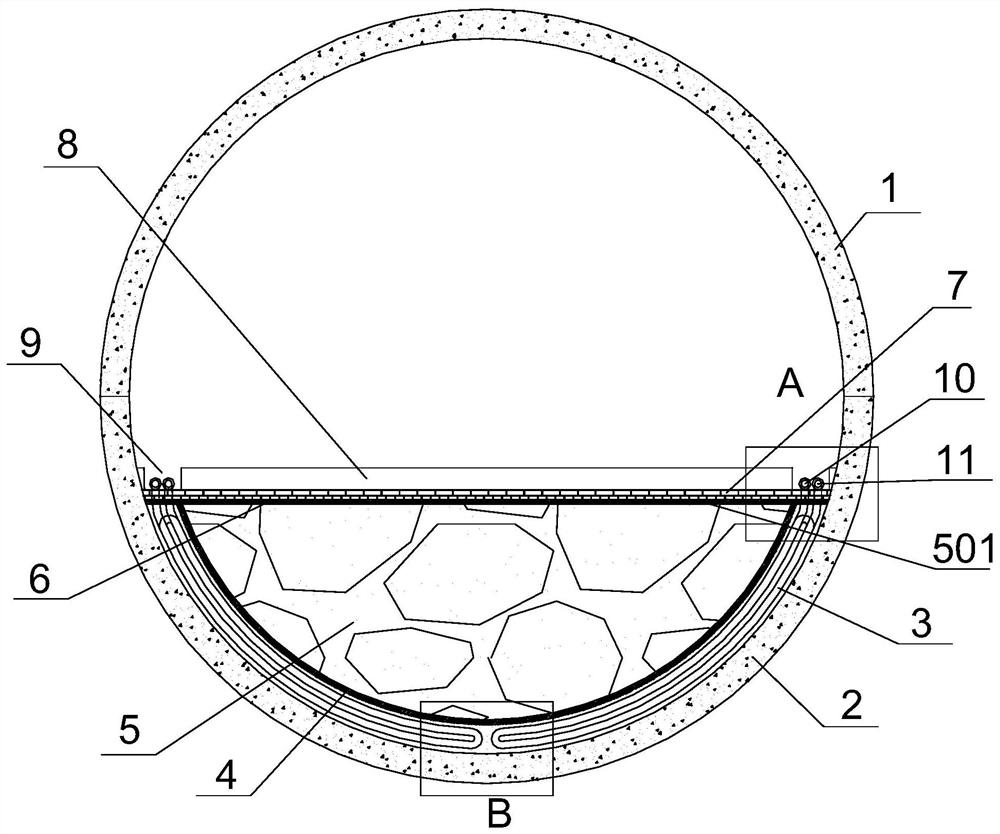

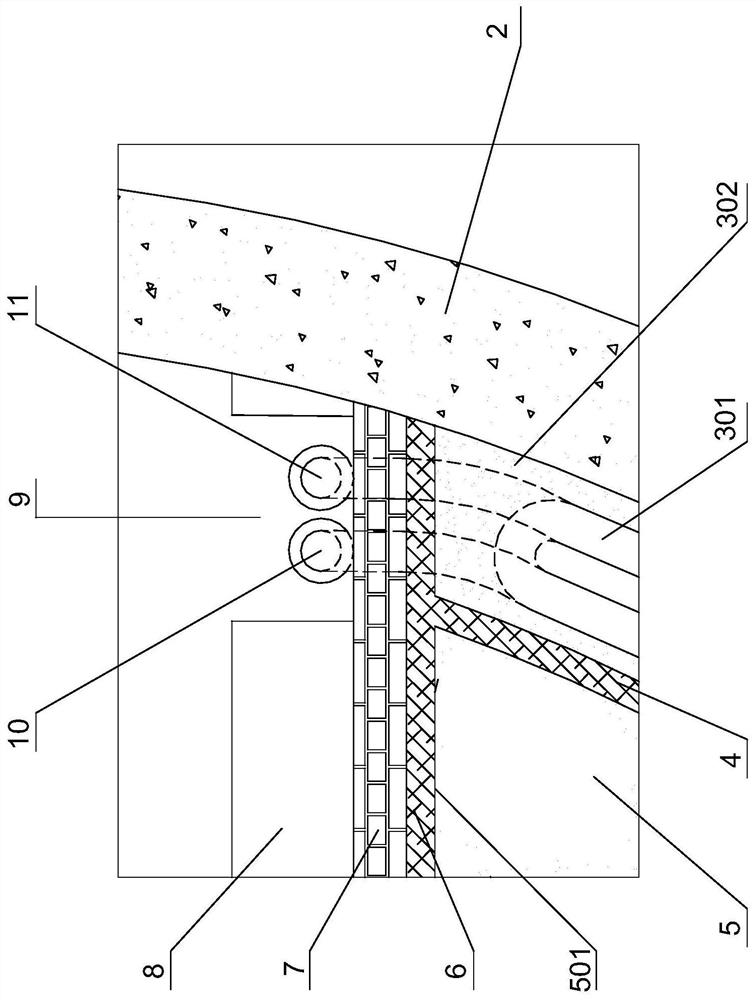

[0045] Examples, see Figure 1 to Figure 4 Shown: the high thermal conductivity geothermal energy heat exchange tunnel system, including the upper tunnel lining 1 and the lower tunnel inverted arch 2 that cooperate with each other. That is, viewed in cross-section, the second tunnel lining 1 and the tunnel invert 2 form a closed ring.

[0046] Further speaking:

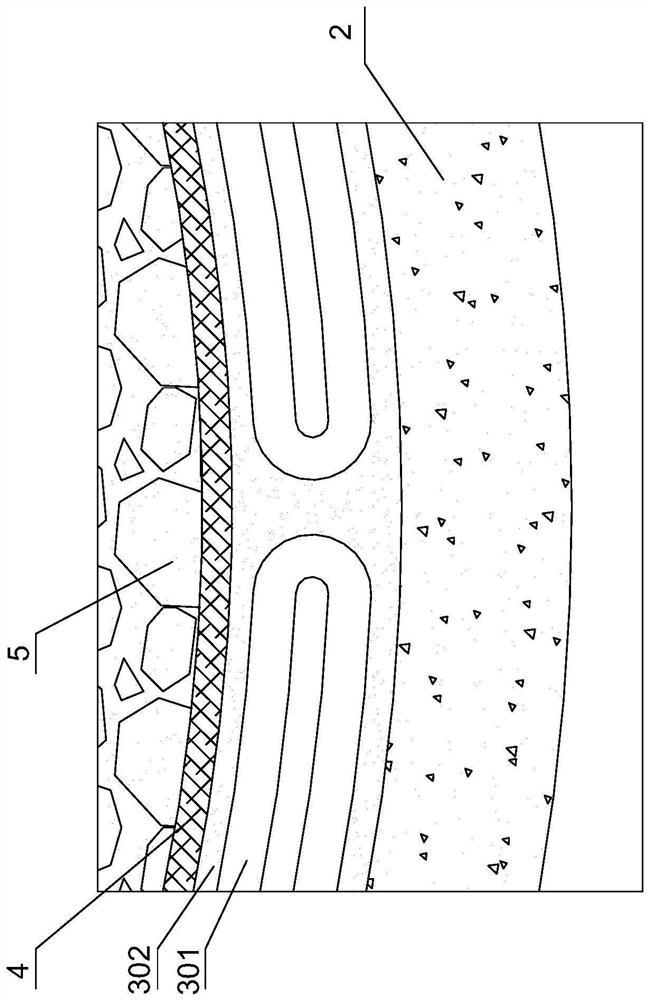

[0047]A patch type prefabricated geotextile bag heat exchange layer 3 is laid on the upper surface of the tunnel invert 2 . The patch-type prefabricated geotextile bag heat exchange layer 3 includes a geotextile bag (not shown in the figure), a heat exchange tube 301 and a high thermal conductivity filler 302 located in the geotextile bag. Among them, the length of the geotextile bag is prefabricated according to the design requirements; comprehensively considering the convenience of on-site construction, the heat exchange tube 301 can be arranged in full width or half width, and the heat exchange tube 301 can be ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com