A prefabricated composite wall panel for a green building

A composite wall panel and green building technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of high steel resource consumption, unfavorable resource conservation, and increased installation costs, achieving less material consumption, improved sound insulation performance, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

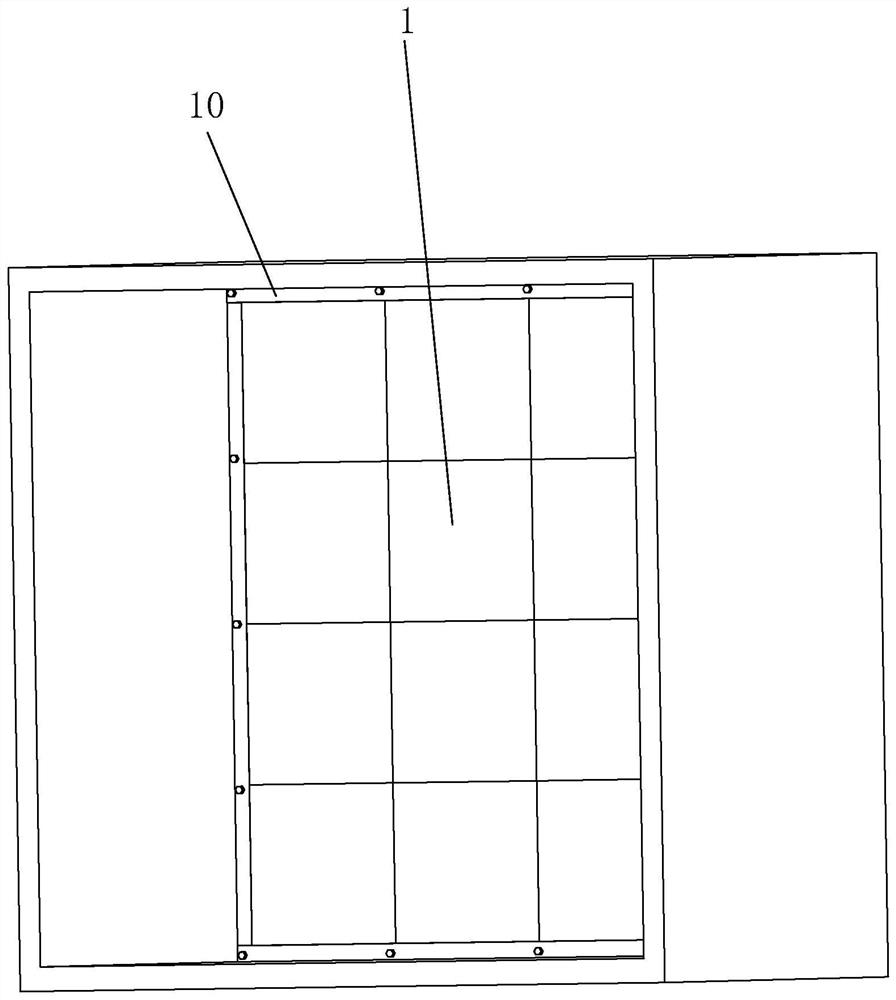

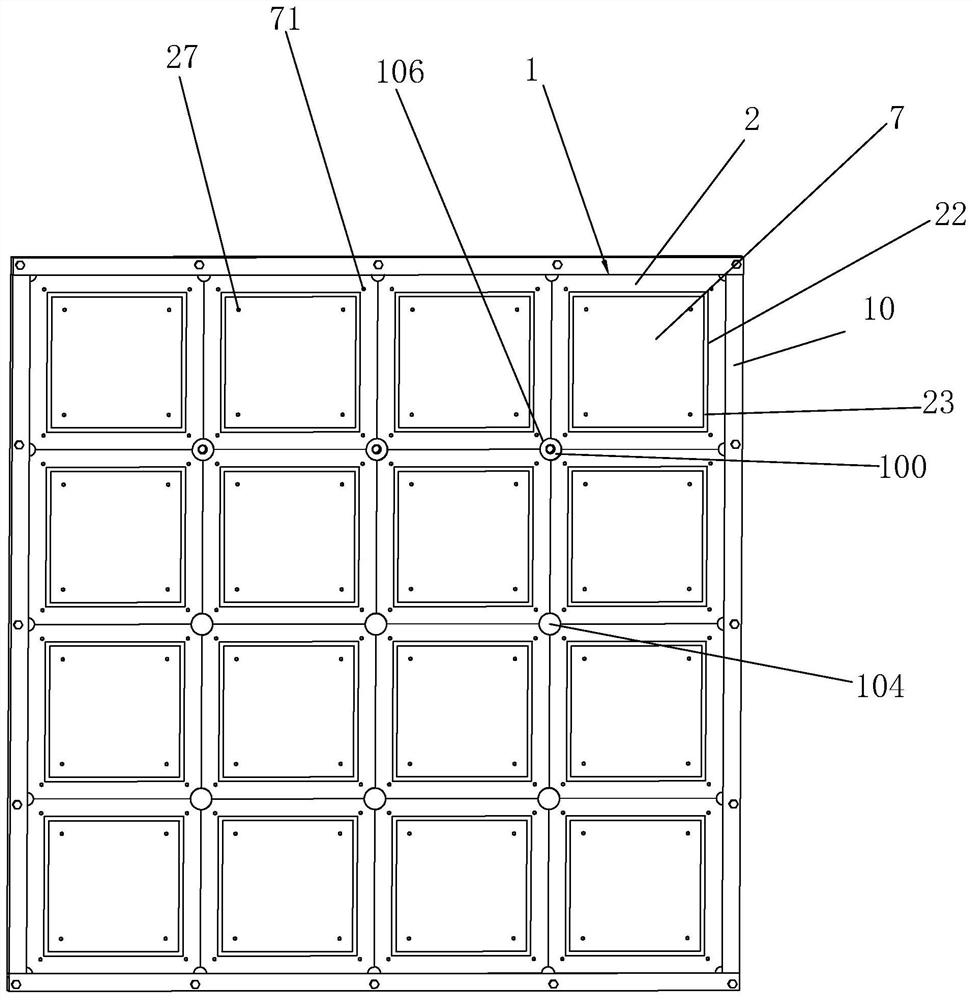

[0047] refer to figure 1 and figure 2 , is a prefabricated composite wall panel for a green building disclosed in the present invention, comprising a combined composite panel 1, a mounting strip 10 for assembling the combined composite panel 1, and a fixing piece 100 fixedly connected to the wall surface, the fixing piece 100 It is used for fixedly connecting the combined composite board 1 to the wall.

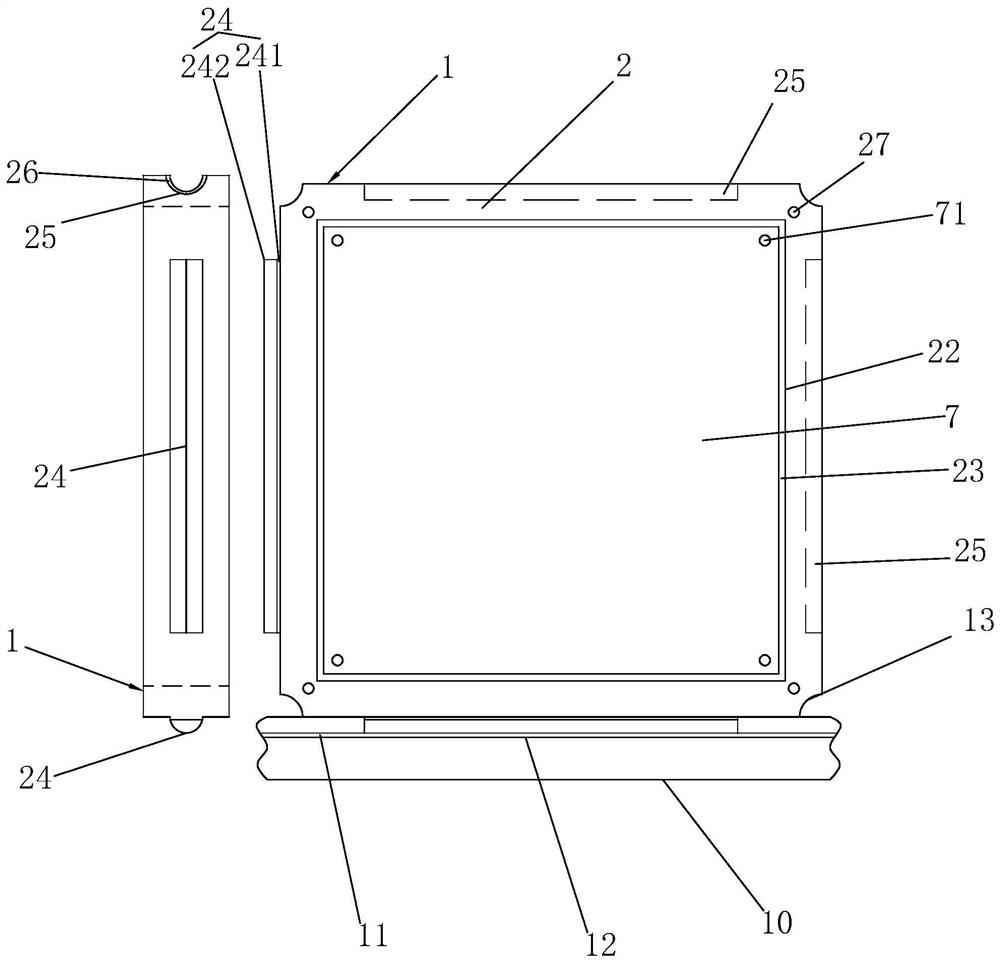

[0048] refer to image 3 and Figure 4 The combined composite board 1 includes a frame body 2 made of aluminum alloy, and a first composite board 3 for sound insulation and heat preservation is detachably connected to the frame body 2, and the first composite board 3 is detachably connected to the frame body 2 facing the wall. side; the second composite board 4 is detachably connected to the frame body 2, and the second composite board 4 is detachably connected to the side of the frame body 2 facing away from the wall; the second composite board 4 has two-way temperature a...

Embodiment 2

[0057] A method for assembling a prefabricated composite wall panel of a green building disclosed by the present invention includes the following steps:

[0058] Step 1. Assembling the primary composite board: firstly fit the first composite board 3 into the first fitting groove 21 of the frame body 2, the rubber sleeve 23 is set on the peripheral side of the first composite board 3, and then the second The composite board 4 is fitted in the second fitting groove 22 of the frame body 2, and the rubber sleeve 23 is sleeved on the peripheral side of the second composite board 4;

[0059] Step 2, assembly of the installation frame: the installation bar 10 is fixed on the wall by screws to form an installation frame, and the assembly groove 11 of the installation bar 10 faces the center of the installation frame;

[0060] Step 3: Assembling the surface of the primary composite wall panel, a plurality of primary composite panels are fitted and installed in the installation frame, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com